You might not notice galvanized steel strip at first glance, but it plays a vital role in building projects around you. This material stands out for its ability to resist corrosion and handle tough conditions. With its strong, durable nature, you can count on it to support structures for years. Its versatility lets you use it in many ways, from roofing to frames. When you choose the right materials, you help your project last longer and perform better.

Key Takeaways

- Galvanized steel strip resists corrosion, making it ideal for harsh environments.

- The zinc coating protects the steel, extending its lifespan and reducing maintenance costs.

- Choose the right hardness level—soft, semi-hard, or full hard—based on your project needs.

- Different spangle types offer various finishes; select zero spangle for a smooth look or big spangle for decoration.

- Galvanized steel strip is versatile; use it in construction, automotive, appliances, and more.

- Investing in galvanized steel strip saves money over time due to its durability and low upkeep.

- Proper handling and installation ensure the material performs well and lasts longer.

- WITOP’s quality control and packaging guarantee reliable products that arrive in excellent condition.

Galvanized Steel Strip Overview

Definition and Production

A galvanized steel strip is a thin strip of carbon steel coated with zinc. You often see this material in construction because it resists corrosion and stands up to harsh environments. The zinc layer protects the steel from rust and damage, making it a reliable choice for many building needs. You can find galvanized steel strip in beams, columns, and other metal structures.

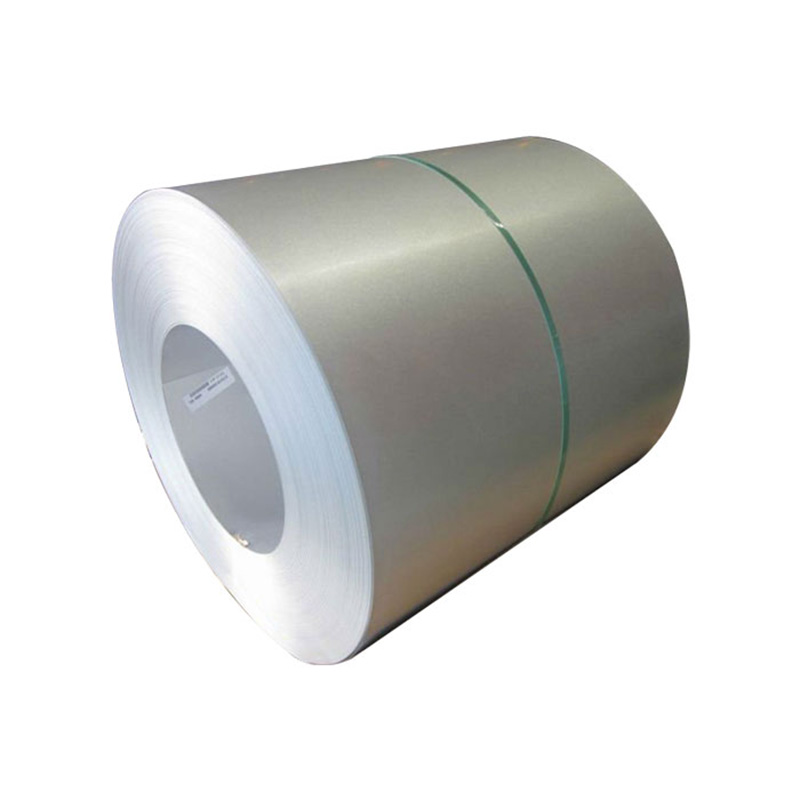

Hot-Dip Galvanizing Process

The most common way to produce galvanized steel strip is the hot-dip galvanizing process. In this method, manufacturers immerse steel strips in molten zinc. This continuous process covers the steel with a strong, even layer of zinc. WITOP uses this advanced hot-dip process to ensure each strip gets full protection. This method allows for high-speed production and consistent quality, which is important for large construction projects.

Zinc Coating Benefits

The zinc coating on galvanized steel strip offers several benefits:

- It acts as a barrier against moisture and chemicals.

- It prevents rust and extends the life of the steel.

- It provides a shiny, attractive finish.

You get a product that lasts longer and needs less maintenance. This makes galvanized steel strip a smart investment for any project.

Key Properties

Corrosion and Heat Resistance

Galvanized steel strip stands out for its resistance to corrosion. The zinc layer shields the steel from water, air, and other elements that cause rust. You can use it in places with high humidity or exposure to chemicals. It also handles heat well, so it works in environments with changing temperatures.

Mechanical Strength

You can rely on galvanized steel strip for its mechanical strength. It supports heavy loads and keeps its shape under pressure. This strength makes it suitable for structural parts in buildings and industrial equipment.

Hardness and Spangle Types

Soft, Semi-Hard, Full Hard

WITOP offers galvanized steel strip in different hardness levels:

- Soft: Easy to bend and shape, perfect for detailed work.

- Semi-Hard: Balances flexibility and strength, good for general construction.

- Full Hard: Very strong, best for parts that need to hold up under stress.

You can choose the right hardness for your specific project needs.

Zero, Small, Regular, Big Spangle

The surface of galvanized steel strip can show different spangle patterns. Spangle refers to the crystal-like finish on the zinc coating. WITOP provides several options:

- Zero Spangle: Smooth surface, ideal for painting or visible areas.

- Small Spangle: Fine pattern, often used in appliances.

- Regular Spangle: Standard look for most construction uses.

- Big Spangle: Bold pattern, sometimes chosen for decorative purposes.

Tip: Choosing the right spangle and hardness helps you match the material to your project’s demands. For example, use zero spangle for a clean look or full hard for extra strength.

These features make galvanized steel strip a versatile and dependable material for construction and industry. You get a product that adapts to many uses, stands up to tough conditions, and delivers lasting value.

Benefits in Construction

Corrosion Protection

Longevity in Harsh Environments

When you choose galvanized steel strip for your building project, you gain powerful protection against corrosion. The zinc coating forms a shield that slows down oxidation and keeps the steel safe. You see this benefit most clearly in places with high humidity or exposure to chemicals. The zinc acts as a sacrificial layer. Even if it starts to corrode, it protects the steel underneath.

The zinc coating acts as a shield, slowing down oxidation and preserving the metal for much longer. The zinc serves as a sacrificial material; even if it corrodes, it protects the underlying steel.

You can rely on galvanized steel strip in harsh environments. It stands up to moisture, rain, and corrosive substances. This means your structures last longer and need fewer repairs. You spend less time worrying about rust and more time focusing on your project’s success.

- Resistance to oxidation

- Prolonged lifespan of the material

- Reduced maintenance costs

- Ability to withstand adverse conditions such as humidity and corrosive substances

Durability and Strength

Performance Under Stress

Galvanized steel strip gives you impressive durability. You can use it in places where strength matters most. The steel core supports heavy loads and resists bending. The zinc coating adds another layer of toughness. You see reliable performance even when the material faces stress from wind, weight, or vibration.

You can trust galvanized steel strip in structural applications. It keeps its shape and holds up over time. This reliability helps you build safer and stronger buildings. You avoid unexpected failures and keep your project on track.

Cost Efficiency

Maintenance and Lifecycle Savings

You save money when you use galvanized steel strip. The zinc coating means less rust and fewer repairs. You do not need to replace parts as often. This reduces interruptions and keeps your project running smoothly.

Investing in galvanized steel strips means durability and less need for replacement, which directly benefits those managing industrial projects or constructions exposed to harsh conditions, as it reduces interruptions and extends the lifespan of metal structures.

You also spend less on maintenance. The material’s long life lowers your overall costs. You get more value from your investment and see better results in the long run.

Versatility

Range of Applications

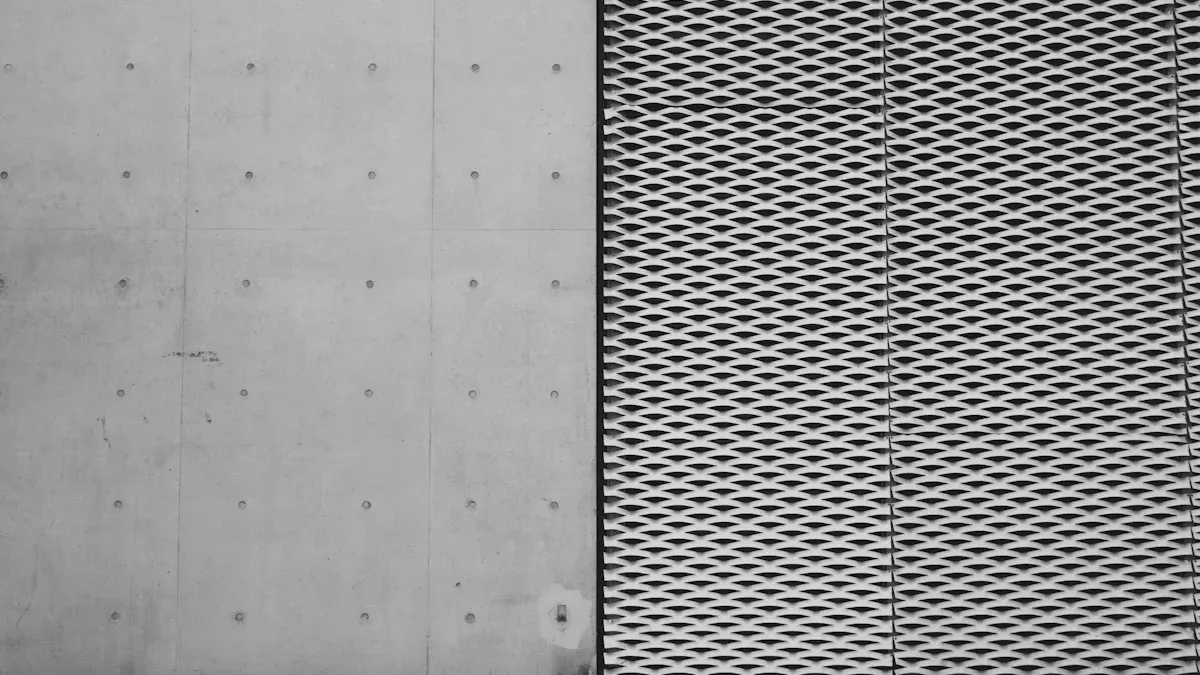

You can use galvanized steel strip in a wide range of projects. This material adapts to many needs in both construction and industry. Its unique combination of strength, corrosion resistance, and flexibility makes it a top choice for builders and engineers.

You find galvanized steel strip providing structural support in many construction projects. It strengthens beams, columns, and metal frameworks. You also see it used for fluid conduction in systems that move water or air, such as plumbing and air conditioning. In industrial settings, it works well for transferring liquids and granules, especially in sugar and alcohol plants.

Here are some common uses in construction and industry:

- Provides structural support for buildings and infrastructure.

- Enhances durability and resists corrosion in harsh environments.

- Used for fluid conduction in water and air conditioning systems.

- Ideal for fences, scaffolding, and metal structures.

- Applied in chemical and petrochemical industries.

- Used in roofing and structural profiles.

You also benefit from its versatility in residential, commercial, and industrial spaces. In homes, you can use galvanized steel strip to protect electrical cables from impacts and exposure. In commercial buildings, it keeps cables safe and ensures long-lasting performance. Industrial areas that do not face aggressive chemicals or extreme conditions rely on this material for safety and economy. Garages and parking lots use it to guard against light impacts and moisture.

Here is how you might use galvanized steel strip in different settings:

- Residences: Protects electrical cables from damage and exposure.

- Commercial spaces: Keeps cables safe in stores, offices, and buildings, offering durability and cost savings.

- Industries: Suitable for areas with low risk, where you need reliable protection without exposure to harsh chemicals.

- Garages and parking lots: Shields against minor impacts and moisture, helping maintain safety.

WITOP’s strict quality control and advanced packaging add another layer of reliability. Each steel strip passes through careful inspection, so you receive a product that meets high standards. The three-layer export package protects the material from moisture and damage during transport. This attention to detail means you can trust the product to arrive in excellent condition, ready for your project.

Note: When you choose a versatile material like galvanized steel strip, you open up more possibilities for your designs. You can use it in many ways, knowing it will perform well and last a long time.

Galvanized Steel Strip Applications

Building and Infrastructure

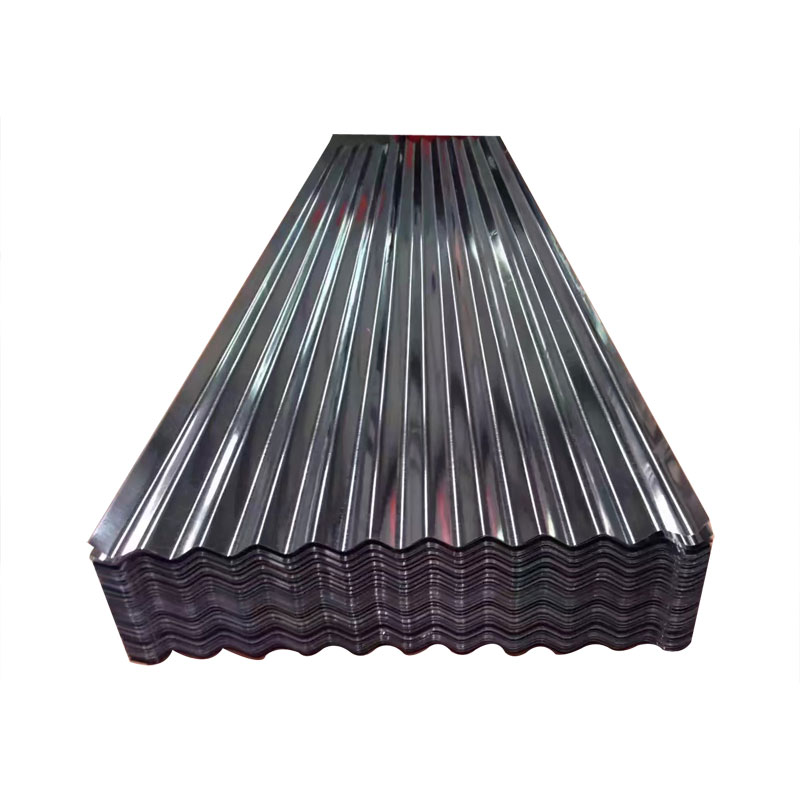

Roofs, Doors, Windows, Furring Channels

You see galvanized steel strip used in many parts of buildings and infrastructure. This material supports roofs, frames doors and windows, and forms metal furring channels. You can rely on it for stability and safety in construction. Builders choose it for its ability to resist moisture and heat. You also find it in places where you need to secure and tie structures, pipes, and cables. Electricians use it to hold cables and wires in place, keeping systems safe from weather. In factories, you use it to tie loads, secure machine parts, and assemble ventilation ducts. Farmers depend on it for fencing, equipment support, and fixations because it lasts a long time.

- Secures and ties structures, pipes, and cables

- Supports roofs, doors, and windows

- Forms metal furring channels for walls and ceilings

- Holds cables and wires in electrical installations

- Ties loads and secures machine components in industry

- Assembles ventilation ducts, resisting heat and moisture

- Builds fences and supports equipment in agriculture

Tip: You can choose the right thickness and width for your project. WITOP offers a wide range of specifications to fit your needs.

| Specification Type | Minimum | Maximum |

|---|---|---|

| Width of strip | 700 mm | 1,600 mm |

| Thickness of strip | 0.25 mm | 1.55 mm |

Automotive Industry

Body Shells, Chassis, Fuel Tanks

You find galvanized steel strip in the automotive industry because it offers strength and protection. Car makers use it for body shells, chassis, and fuel tanks. You get a material that resists corrosion and stands up to tough conditions. This means vehicles last longer and need less maintenance. You also benefit from its versatility, as it fits many parts and designs.

| Benefit | Description |

|---|---|

| Resistance to Corrosion | The zinc layer protects steel and extends the lifespan of car parts. |

| Proven Durability | You see fewer repairs because the material withstands harsh environments. |

| Versatility of Applications | You use it in many sectors, including automotive, construction, and equipment manufacturing. |

Note: WITOP supplies galvanized steel strip to international markets, meeting the needs of car makers in Africa, the Middle East, and Southeast Asia.

Appliances and Containers

Home and Industrial Uses

You use galvanized steel strip in appliances and containers for both home and industrial settings. Manufacturers choose it for washing machines, refrigerators, and air conditioners. You also see it in storage containers and bins. The material protects against rust and damage, so products last longer. You can select the right hardness and spangle type for each application, making it easy to match your needs.

WITOP’s commitment to quality and careful packaging ensures you receive reliable products. You get steel strips that arrive in good condition, ready for use in your project. The company’s strong international presence means you can trust their products in many industries around the world.

Tip: When you select galvanized steel strip, you gain flexibility for many applications. You can use it in construction, automotive, appliances, and more.

Comparison with Other Materials

Stainless Steel vs. Galvanized Steel Strip

Cost and Performance

When you compare stainless steel and galvanized steel strip, you notice important differences in cost and performance. Stainless steel resists corrosion very well, but it often costs much more. Galvanized steel strip gives you strong protection against rust at a lower price. You can use it for large projects without breaking your budget.

Here is a table that shows how galvanized steel strip stands out:

| Advantage | Description |

|---|---|

| Cost-effective | Galvanized steel offers an economical solution for large-scale projects compared to stainless steel. |

| Versatility of use | You can use it in fastenings, packaging, temporary structures, and industrial reinforcements. |

| Easy handling | Galvanized steel is more malleable, so you cut and bend it easily, which speeds up installation. |

| Suitable for dry areas | In dry or moderately humid environments, galvanized steel meets most industrial and fastening needs. |

Tip: If you want a material that balances cost and performance, galvanized steel strip is a smart choice for many construction and industrial uses.

Aluminum vs. Galvanized Steel Strip

Weight and Corrosion Resistance

Aluminum is much lighter than steel. You might choose aluminum when you need to reduce weight, such as in transportation or portable structures. Galvanized steel strip, however, offers greater strength and durability. It resists bending and holds up under heavy loads.

Both materials protect against corrosion, but galvanized steel strip provides a tough zinc coating that shields the steel from moisture and chemicals. You get reliable performance in harsh environments. Aluminum does not rust, but it can corrode in salty or acidic conditions. Galvanized steel strip works well in places with changing weather and exposure to water.

- Aluminum: Lightweight, easy to move, good for portable projects.

- Galvanized steel strip: Strong, durable, excellent for structural support and long-term use.

Note: You should consider the needs of your project. If you need strength and corrosion resistance, galvanized steel strip is often the better option.

Non-Galvanized Steel vs. Galvanized Steel Strip

Maintenance and Longevity

Non-galvanized steel can rust quickly when exposed to moisture. You need to paint or coat it often to keep it safe. Galvanized steel strip comes with a zinc layer that protects the steel for years. You spend less time and money on maintenance.

You see longer service life with galvanized steel strip. It stands up to rain, humidity, and chemicals. Non-galvanized steel may need frequent repairs and replacements. Galvanized steel strip helps you build structures that last and require less upkeep.

- Non-galvanized steel: Needs regular maintenance, shorter lifespan.

- Galvanized steel strip: Low maintenance, long-lasting, reliable in tough conditions.

Choosing galvanized steel strip means you get a material that saves you time and money over the life of your project.

Real-World Examples

Residential Projects

Enhanced Service Life

You want your home to last for generations. When you use galvanized steel strip in residential projects, you add years to the life of your structure. Builders often choose this material for roofing, window frames, and wall channels. You see fewer repairs because the zinc coating protects against rust and moisture. For example, in coastal areas, homes face salty air and high humidity. Galvanized steel strip stands up to these harsh conditions. You enjoy peace of mind knowing your house will stay strong and safe.

Homeowners in Southeast Asia report that their roofs and window frames remain free from corrosion, even after many rainy seasons. You can expect similar results when you select this material for your own project.

Commercial and Infrastructure

Structural Reliability

You need reliable materials for commercial buildings and infrastructure. Galvanized steel strip provides the strength and durability that large projects demand. Contractors use it for beams, columns, and furring channels in shopping centers, schools, and hospitals. You see this material in bridges and public transportation hubs. The zinc coating keeps the steel strong, even when exposed to heavy traffic and changing weather.

- Shopping centers use galvanized steel strip for support beams.

- Hospitals rely on it for window and door frames.

- Bridges and train stations benefit from its resistance to corrosion.

| Project Type | Application | Benefit |

|---|---|---|

| Shopping Center | Support beams | Long-lasting strength |

| Hospital | Window and door frames | Reliable protection |

| Bridge | Structural components | Corrosion resistance |

You notice that these buildings require less maintenance. You save money and time because the material holds up under stress.

International Success Stories

WITOP’s Export Projects

You see the impact of WITOP’s products around the world. WITOP exports galvanized steel strip to Africa, the Middle East, and Southeast Asia. Construction companies in these regions use it for both residential and commercial projects. In Africa, builders use it for school roofs and water tanks. In the Middle East, you find it in airport terminals and shopping malls. Southeast Asian manufacturers rely on it for home appliances and storage containers.

WITOP’s strict quality control and advanced packaging ensure that you receive steel strips in perfect condition, no matter where your project is located.

You can trust WITOP’s galvanized steel strip to deliver consistent results. When you choose this material, you join builders and engineers worldwide who value reliability and performance.

Selection and Usage Tips

Choosing the Right Grade

Matching Hardness and Spangle to Application

You need to select the right grade of galvanized steel strip for your project. Start by thinking about where you will use the material. If you work in an environment with high humidity, chemicals, or changing temperatures, choose a grade with strong corrosion resistance and durability. For example, if you install galvanized pipes in areas with steam or impurities, pick a grade that can handle these tough conditions.

WITOP offers several hardness levels—Soft, Semi-Hard, and Full Hard. Soft grades work well for bending and shaping. Semi-Hard gives you a balance between flexibility and strength. Full Hard is best for parts that need to withstand heavy loads or pressure.

Spangle type also matters. Zero spangle gives you a smooth surface, which is perfect for painting or visible areas. Small, regular, and big spangle options let you match the finish to your design needs.

Tip: Always match the hardness and spangle type to your application. This helps you get the best performance and appearance for your project.

Installation Best Practices

Handling and Joining

Proper installation ensures your galvanized steel strip performs well and lasts longer. You should take care during transportation, handling, and storage. Check the integrity of the material when you receive it. Stack smaller profiles on top of larger ones to prevent deformation. Tie and align lots to reduce the risk of distortion.

When you work with galvanized steel strip, you can bend, cut, weld, and shape it easily. The protective zinc layer stays intact, so you do not lose corrosion resistance. This material offers excellent adhesion and dimensional stability, which helps during assembly and finishing.

- Handle and store profiles carefully to maintain integrity.

- Stack smaller profiles on larger ones.

- Align and tie lots to minimize distortion.

- Use galvanized steel strip in areas exposed to weather, moisture, or chemicals.

- Shape and join the material without damaging its protective layer.

Note: Careful handling and proper joining techniques help you avoid damage and ensure long-lasting results.

Quality and Packaging

Ensuring Product Integrity

Quality control and packaging play a big role in protecting your galvanized steel strip. WITOP uses advanced testing equipment to check tensile strength and dimensional retention. You receive steel strips that meet strict standards.

Packaging matters, especially for transport and storage. WITOP uses a three-layer export package to shield the material from moisture and damage. The packaging materials fit the steel strips and seals perfectly, which keeps everything secure.

- Choose packaging that matches the size and shape of your steel strips.

- Make sure seals and strapping devices align with the profile.

- Consider the operational environment—humidity, dust, and corrosion may require reinforced finishes.

- Select galvanized steel strips for added surface protection against oxidation.

Tip: Work with reputable suppliers like WITOP. Their focus on quality control and packaging helps you get reliable products that arrive in perfect condition.

By following these tips, you make smart choices for your project. You get the right grade, install it correctly, and protect your investment with proper quality control and packaging.

You see galvanized steel strip as a key material in modern construction. Its carbon structure supports heavy loads and high pressure. The zinc coating protects against corrosion and reduces oxidation. You spend less on maintenance because the material lasts longer. The affordable price makes it a smart choice for many projects. When you choose high-quality options like WITOP, you help your buildings last longer and perform better.

- Increased resistance for demanding projects

- Corrosion-free performance in harsh environments

- Low maintenance for long-term savings

- Affordable price for greater value

Smart material choices lead to stronger, longer-lasting results.

FAQ

What is the main advantage of using galvanized steel strip in construction?

You get strong protection against rust and corrosion. The zinc coating helps your structures last longer, even in tough environments. You also save money on maintenance over time.

How do I choose the right hardness for my project?

You should match the hardness to your needs.

- Soft: Easy to bend

- Semi-Hard: Balanced strength

- Full Hard: Maximum durability

Tip: Use full hard for heavy-duty parts.

Can I paint over galvanized steel strip?

Yes, you can paint over it. Clean the surface first. Use a primer made for galvanized steel. This helps the paint stick and last longer.

What thickness and width options are available?

You can choose from a wide range.

| Thickness (mm) | Width (mm) |

|---|---|

| 0.09 – 5.00 | 20 – 599 |

Select the size that fits your project.

Is galvanized steel strip safe for outdoor use?

Yes, you can use it outdoors. The zinc coating protects against rain, sun, and changing temperatures. Your structures stay strong and resist rust.

How should I store galvanized steel strip before use?

Store it in a dry, covered area. Keep it off the ground. Use the original packaging to protect against moisture and damage.

Does galvanized steel strip require special tools for installation?

No, you can use standard tools for cutting, bending, and joining. The material is easy to work with. Always handle with care to keep the zinc coating intact.