Introduction

Steel sheets are the anchor of modern construction, manufacturing, and fabrication industries. From building rooftops to automobile panels and architectural facades, steel sheets are everywhere. Their durability, versatility, and cost-effectiveness make them an indispensable material across a wide range of sectors.

In this in-depth guide, we’ll explore everything you need to know about steel sheet, including its various types such as flat steel sheet, perforated steel sheet, steel roof sheets, and decking sheet. We’ll also discuss steel sheet metal characteristics and provide insights into steel sheet price trends.

What is Steel Sheets?

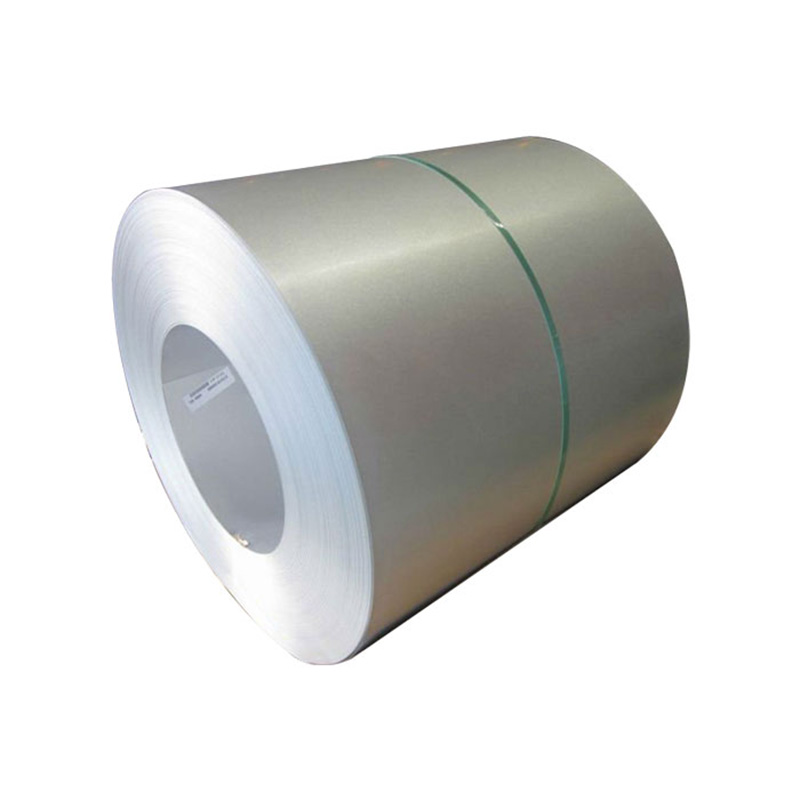

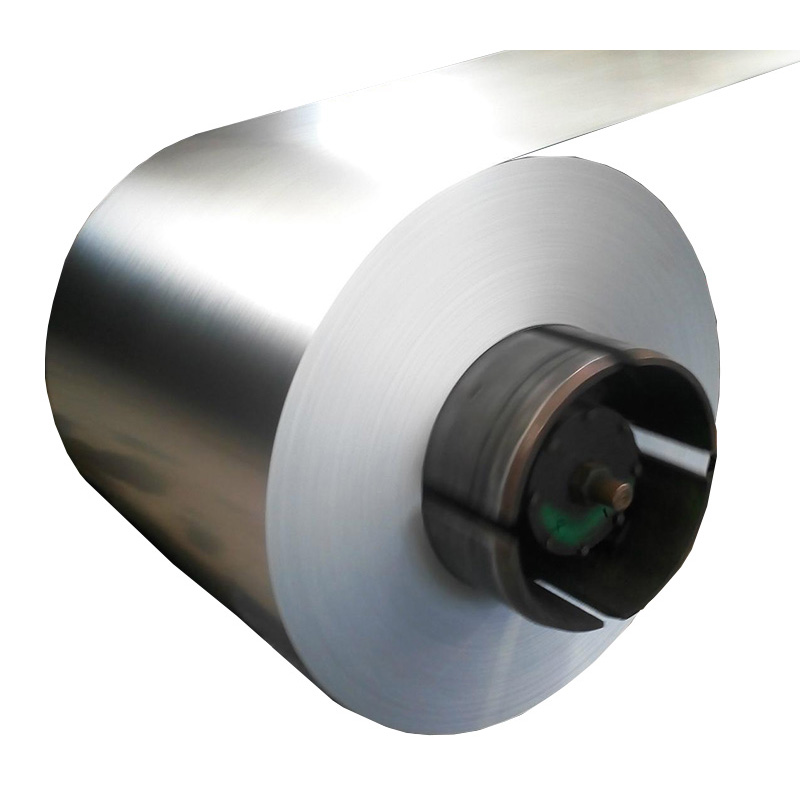

A steel sheet is a thin, flat piece of steel that is formed through an industrial rolling process. It can be cold-rolled or hot-rolled depending on the desired finish and structural strength.

Steel sheets vary in thickness, with thinner sheets classified as “foil” or “leaf” and thicker variants referred to as “plates.”

Average Steel Sheets Thicknesses

- 0.12 mm to 3 mm (sheet metal range)

- 3 mm and above (plate metal)

Kinds of Steel Sheets and their applications

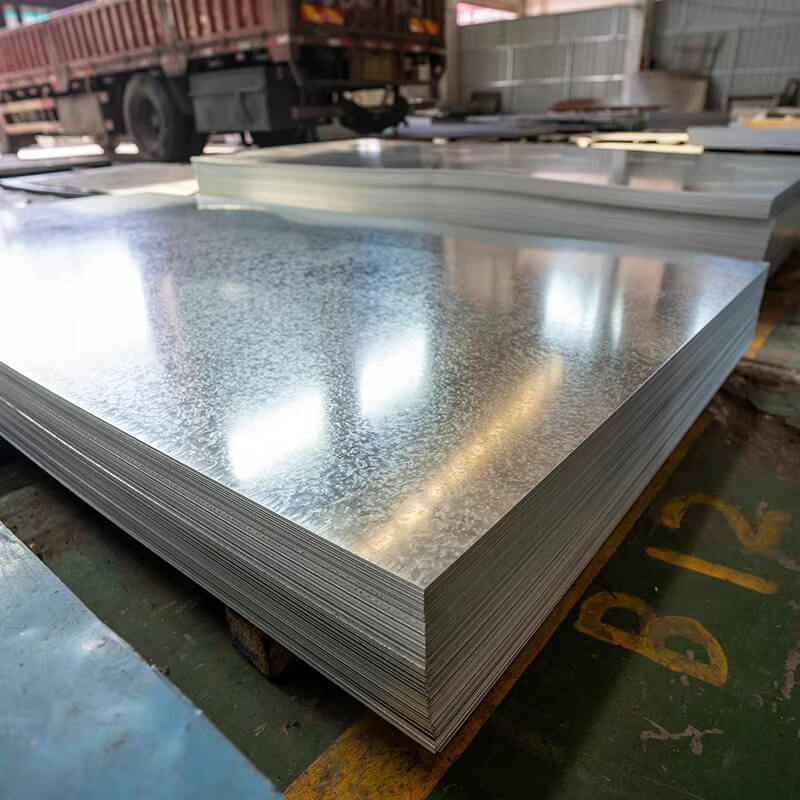

1. Flat Steel Sheets

Flat steel sheet is one of the most widely used forms of sheet steel. As the name suggests, it is completely flat and smooth, making it ideal for fabrication and machining. Common applications include

- Automotive body panels

- Appliances (refrigerators, washing machines)

- Machine parts

- Construction frames

Flat steel sheet is available in both cold-rolled and hot-rolled forms. Cold-rolled flat sheets are smoother and dimensionally precise, whereas hot-rolled flat sheets are more affordable and rugged.

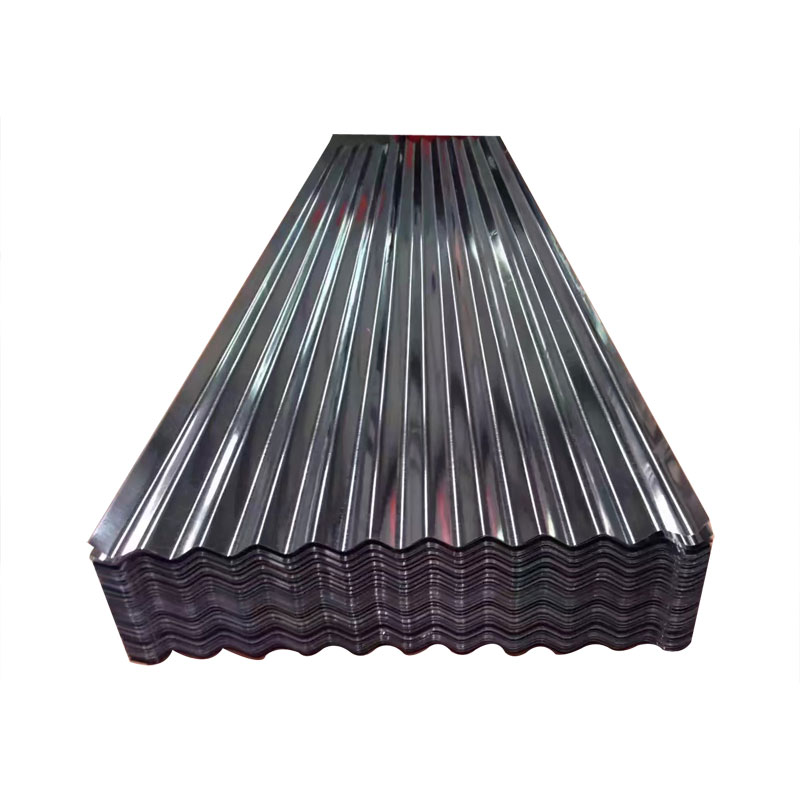

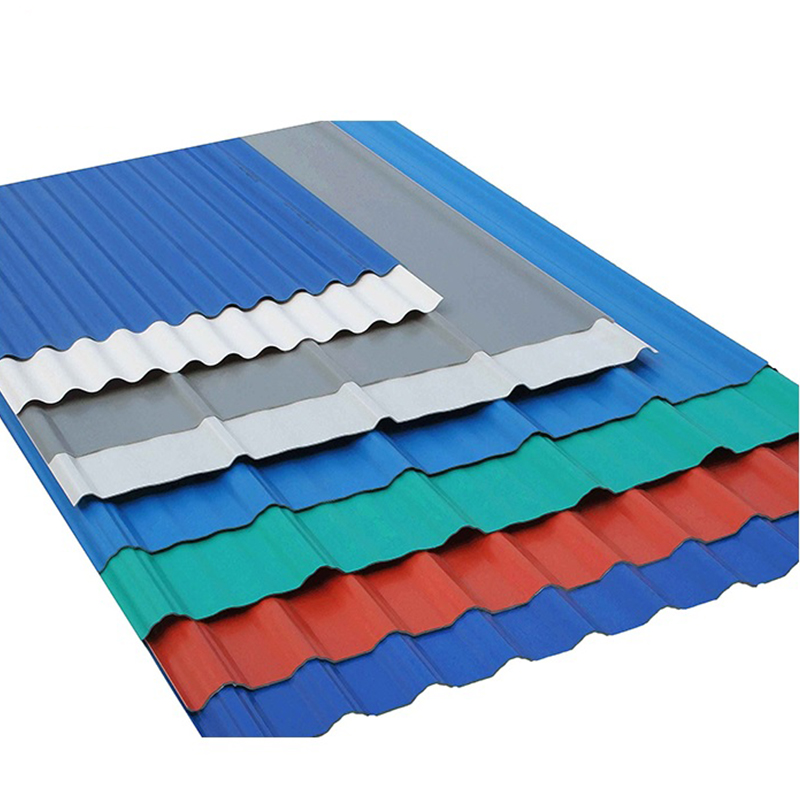

2. Steel Roof Sheets

Steel roof sheets are specially designed sheets used for roofing applications in residential, commercial, and industrial structures.

Types of Steel Roof Sheets:

- Corrugated sheets

- IBR (Inverted Box Rib) sheets

- Standing seam sheets

- Color-coated and galvanized roofing sheets

Advantages:

- Weather-resistant

- Fireproof and insect-resistant

- Long lifespan with minimal maintenance

- Easy to install and lightweight

With increasing demand for durable and cost-effective roofing solutions, steel roof sheets have become a popular choice in both urban and rural construction projects.

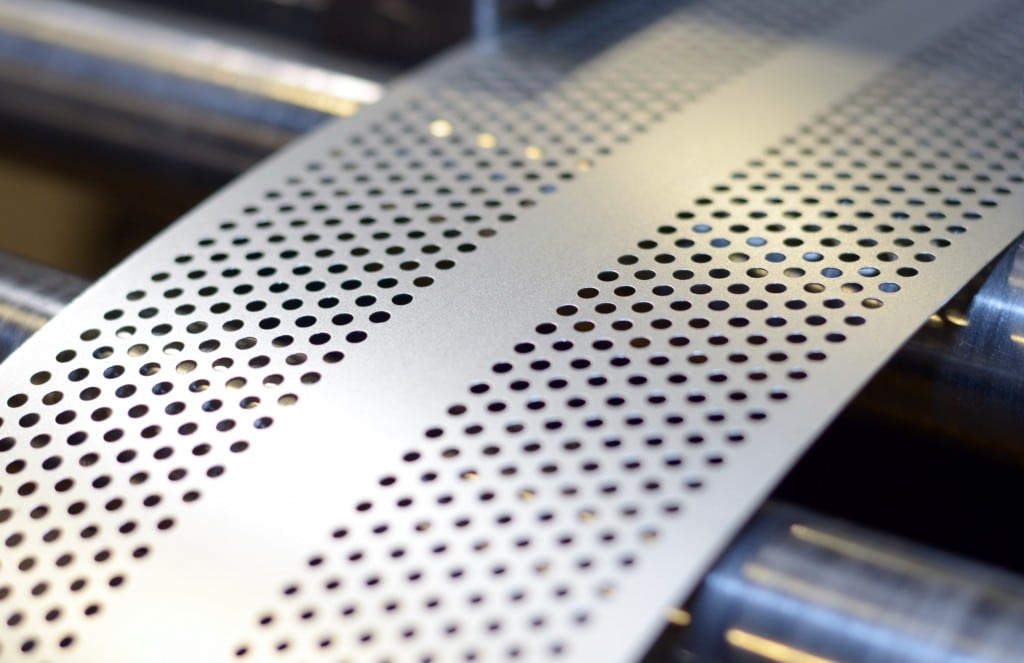

3. Perforated Steel Sheet

Perforated steel sheet consists of a flat steel sheet that has been mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes.

Advantages:

- Excellent airflow and light filtration

- Stylish architectural appeal

- Noise reduction and sound absorption

- Lightweight yet strong

Common Applications include

- Ventilation panels

- Acoustic panels

- Facades and cladding

- Machine guards and screens

- Decorative elements

Perforated sheets come in various patterns, including round holes, square holes, slotted holes, and custom shapes based on specific design requirements.

4. Decking Sheet

Decking sheet, also known as floor decking sheet, is a high-strength, galvanized steel sheet used as a structural platform in construction.

Features:

- High load-bearing capacity

- Acts as a permanent shuttering system

- Easy to install with interlocking features

- Reduces construction time and labor cost

Common Applications include

- Multi-story buildings

- Warehouses and mezzanines

- Commercial complexes and shopping malls

- Residential apartments

Decking sheets not only add strength to concrete slabs but also help reduce the dead weight of structures, making them ideal for high-rise buildings.

Steel Sheet Metal: Properties and Advantages

Steel sheet metal is widely appreciated for its flexibility in shaping, forming, and welding. It can be bent, cut, and fabricated into almost any shape, making it highly useful in both industrial and artistic applications.

Key Properties of Steel Sheet Metal:

- High tensile strength

- Corrosion resistance

- Thermal conductivity

- Aesthetic appeal

Advantages:

- Long service life

- Environmentally friendly and recyclable

- Cost-effective and readily available

- Can be painted, powder-coated, or anodized

From industrial enclosures to ornamental designs, steel sheet metal has proven its utility time and time again.

Steel Sheet Price: What Affects the Cost?

The steel sheet price can vary significantly depending on several factors. Understanding these variables can help buyers make more informed purchasing decisions.

1. Raw Material Costs

2. Type of Steel

3. Sheet Thickness and Size

4. Finishing and Coating

5. Market Demand and Supply Chain

Example Price Range (as of 2025 estimates)

Mild steel sheet (1 mm): 4.6 RMB to 6.7 RMB per kg

Galvanized sheet (1 mm): 6.3 to 8.4 RMB per kg

Perforated steel sheet: 8.4 RMB to 12.6 RMB per kg depending on pattern

Roofing sheet (corrugated or IBR): 25.2 RMB to 50.5 RMB per piece (based on size)

Note: Prices vary by region, supplier, and specifications.

Applications of Steel Sheets Across Industries

1. Construction and Infrastructure

2. Automotive Sector

3. Consumer Goods

4. Agriculture

5. Energy and Utilities

6. Architecture and Design

Choosing the Right Steel Sheet: Key Factors

1. Application Requirements

2. Material Type

3. Thickness and Strength

4. Coating and Finish

5. Form Factor

Consult with a steel supplier or engineer to ensure the selected material meets the mechanical and environmental demands of your project.

Maintenance and Handling Tips

Handling:

- Use gloves to prevent rust from fingerprints

- Avoid dragging to prevent surface scratches

- Store in dry, covered areas

Maintenance:

- Clean with non-corrosive detergents

- Inspect regularly for corrosion or damage

- Touch up painted or coated surfaces when scratched

Conclusion

Steel sheets are the quiet workhorses of the modern industrial world. Whether it’s the sturdy flat steel sheets for manufacturing, weatherproof steel roof sheets, ventilation-ready perforated steel sheets, or load-bearing decking sheet, these versatile materials meet an impressive range of needs.

By understanding the various types, applications, and factors affecting steel sheet price, buyers and engineers can make smart, cost-effective decisions for both small and large-scale projects.

From infrastructure to interior design, steel sheet metal continues to shape the world—literally and figuratively.

WITOP steel have 10 corrugation steel lines for galvanized and galvalume roofing sheet with annual capacity of 100000 tons.WITOP steel can print the blue/red/black LOGO and marks on roofing sheet for customers.We can process Wave-Shape and Trapezoid-Shape of corrugated Roofing sheet.

When roofing sheet comes to constructing a long-lasting, aesthetically pleasing, and weather-resistant roof, selecting the right roofing material is essential. Roofing sheets are available in various materials and designs to cater to different climates, budgets, and architectural styles.

In this comprehensive guide, we will explore popular roofing sheet types such as long span aluminium roofing sheet, Milano roofing sheet, Metro tiles roofing sheet, shingles roofing sheet, classic stone coated roofing sheet, aluzinc roofing sheet, bond roofing sheet, iron roof sheet, Metcoppo roofing sheets, and tower aluminium roofing sheet.

We’ll also delve into practical considerations for selecting the ideal aluminium roofing sheet house setup.