Popular Application of aluminum zinc sheet

In recent years, with the continuous development of technology and the improvement of people’s awareness of environmental protection, more and more buildings have started to choose to use the aluminum zinc sheet (galvalume steel plate/alu-zinc steel plate)for decoration.

Firstly, aluminum zinc sheet have excellent performance.

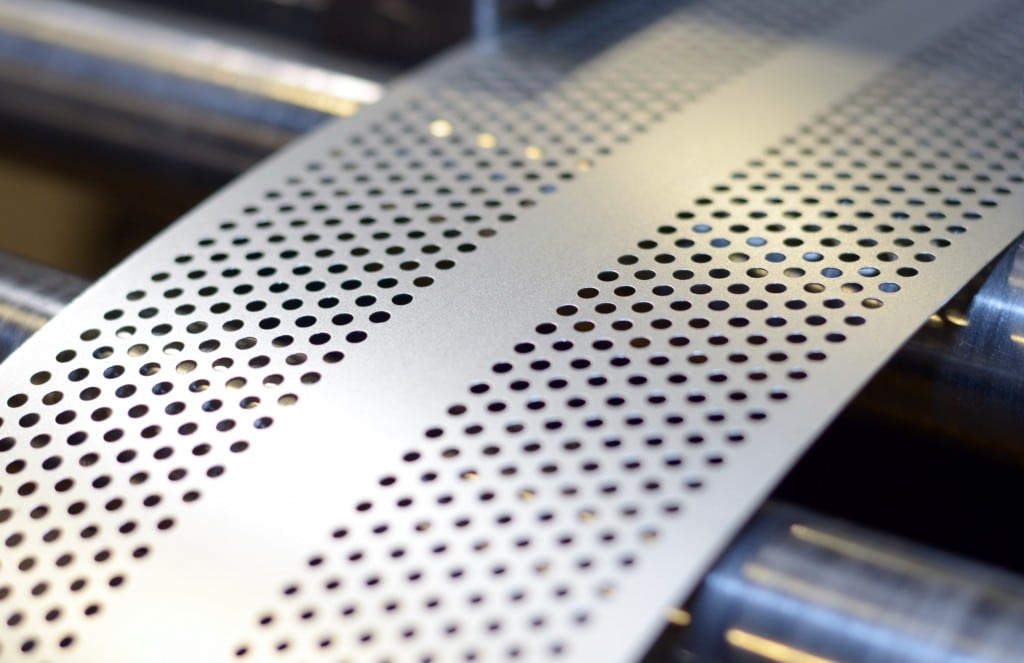

The aluminum zinc sheet adopts advanced technology, which enables the aluminum zinc layer to effectively protect the steel plate from rust and corrosion. This special coating enables aluminum zinc plate to have a longer service life and weather resistance, and can maintain good appearance and performance in various harsh environments. In addition, aluminum zinc plate also have good shear strength, tensile strength, and corrosion resistance, which can meet different building decoration needs.

Secondly, the decoration effect of aluminum zinc sheet is excellent.

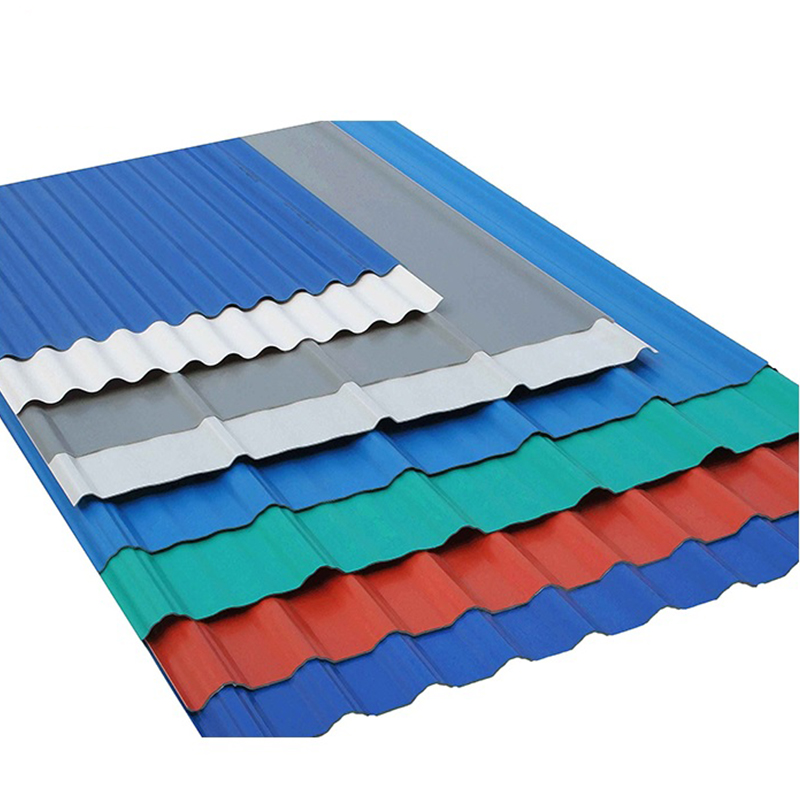

The surface of the aluminum zinc plate adopts advanced nano coating technology, which gives it a high gloss and smoothness and can present a beautiful metallic texture. Aluminum zinc plated panels can also be customized according to architectural design needs, with different colors, textures, and shapes to achieve personalized decoration styles. In addition, aluminum zinc plate can also be used in conjunction with other materials, such as glass, ceramics, etc., to enhance the aesthetics and artistic sense of the building.

Thirdly, aluminum zinc sheet have good environmental performance.

The nano coating used in the aluminum zinc plate has excellent anti fouling performance, can resist the erosion of atmospheric pollutants, and is not prone to detachment and discoloration. In addition, the materials of aluminum zinc plates can be recycled, reducing resource waste and environmental pollution. During the decoration process, aluminum zinc plated panels do not require spraying and baking, saving energy and reducing emissions. Therefore, choosing aluminum zinc plates for building decoration can reduce the impact on the environment and comply with the concept of sustainable development.

Fourthly, the installation and maintenance of aluminum zinc plates are relatively convenient.

Aluminum zinc plates have lower weight and higher stiffness, making them easy to handle and install. During installation, simple fabrication and fixation are required, reducing the difficulty and time of construction. In addition, the maintenance cost of aluminum zinc plates is relatively low, and regular cleaning and maintenance of the coating can maintain their good appearance and performance.

Fifthly, aluminum zinc plates have high economic benefits.

Although the price of aluminum zinc plates is relatively high, their long-term service life and good performance can reduce the cost of maintenance and replacement. In addition, the wet coating process for aluminum zinc plates is more economical compared to traditional spraying, which can reduce construction time and material loss. Therefore, considering its long-term returns and comprehensive cost-effectiveness, more and more buildings are choosing to use aluminum zinc plates for decoration.

In short, with the development of technology and the improvement of environmental awareness, aluminum zinc sheet(galvalume steel sheet/alu-zinc steel sheet) as a new type of building decoration material has become a popular choice in the market. Its excellent performance, excellent decoration effect, good environmental performance, convenient installation and maintenance, and high economic benefits are all important reasons for the increasing use of aluminum zinc plating in buildings.