Introduction

Coated Steel Coils is the keystone of the modern world. From the lofty skyscrapers that define our cities to the home appliances we rely on daily, its capability and skillfulness are unparalleled.

But raw steel has a critical vulnerability: rust. To open up its full potential, steel must be protected from the corrosive forces of moisture and oxygen.

This is where the science of coating comes in. By applying protective layers to a base steel coil, manufacturers create advanced materials that offer decades of durability and aesthetic appeal.

This article will clarify the world of coated steel, exploring the fundamental differences between galvanized and Galvalume coatings, the vibrant world of the ‘color steel coil’, and the captious international trade classifications that make the global steel market possible.

The Groundwork of Protection: Metallic Coatings

Before we can add color, we must first establish a robust defense against corrosion. This is achieved by bonding a metallic coating to the base steel sheet in a continuous process. The two dominant players in this field are Galvanized (GI) and Galvalume (GL) steel.

Galvanized Steel Coil (GI): What’s it all about?

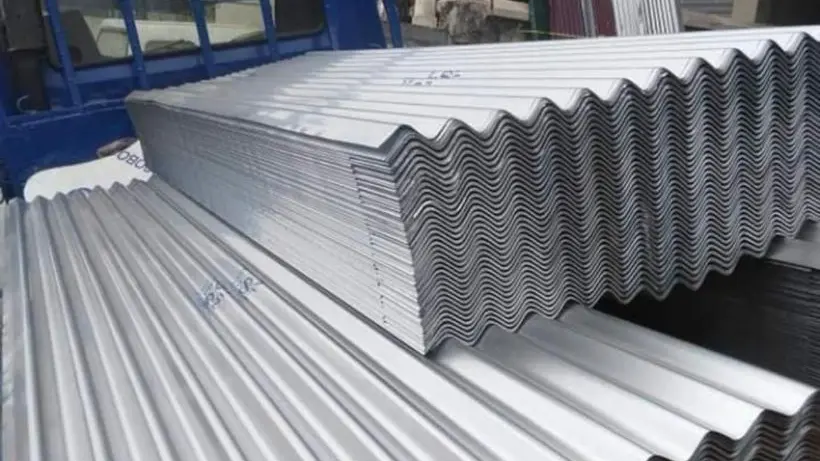

A ‘galvanized steel coil’ is a carbon steel sheet that has been coated with a layer of nearly pure zinc. The most common method is hot-dip galvanizing, where the steel coil is passed through a bath of molten zinc at high temperatures, creating a strong metallurgical bond.

How GI Works: Sacrificial Protection

Zinc provides two forms of protection. First, it acts as a physical barrier, preventing moisture from reaching the steel. More importantly, it offers “sacrificial” or cathodic protection. Zinc is more electrochemically active than iron (steel).

When the coating is scratched or a cut edge is exposed, the zinc will preferentially corrode, “sacrificing” itself to protect the underlying steel. This self-healing property is a major advantage of galvanized steel, especially in applications with many cuts, bends, and drilled holes.

Key Characteristics:

- Composition: 99%+ Zinc coating.

- Protection: Excellent sacrificial protection for cut edges.

- Appearance:Typically features a crystalline, snowflake-like pattern known as “spangle,” which can vary from large to minimized or zero spangle depending on the production process.

- Best For: Environments where the material will be heavily formed or where cut-edge protection is paramount, such as in HVAC ductwork, agricultural equipment, and certain structural components.

Galvalume Steel Coil (GL): The speciality

A ‘Galvalume steel coil’ represents an evolution in coating technology. It is a carbon steel sheet coated with a specific alloy of aluminum and zinc. The internationally recognized composition is approximately 55% aluminum, 43.5% zinc, and 1.5% silicon, which is added to ensure proper adhesion to the steel substrate.

How GL Works: Barrier and Sacrificial Protection

Galvalume combines the best properties of both aluminum and zinc. The aluminum component creates a highly durable and stable oxide barrier that is incredibly resistant to corrosion over the long term. The zinc component provides galvanic protection, though to a lesser degree than pure zinc. This means that while Galvalume offers some sacrificial protection at scratches and cut edges, its primary defense is the robust aluminum barrier.

Key Characteristics:

- Composition: 55% Aluminum-Zinc alloy.

- Protection: Superior long-term barrier protection, offering 2-4 times the corrosion resistance of galvanized steel in many atmospheric conditions.

- Appearance: A smooth, uniform, and typically smaller spangle pattern gives it a more refined and consistent look.

- Best For: Applications where long-term durability and aesthetic consistency are critical, particularly in roofing and architectural cladding. It is the preferred substrate for high-end metal buildings.

Adding Aesthetics and Performance: The Pre-Painted Steel Coil

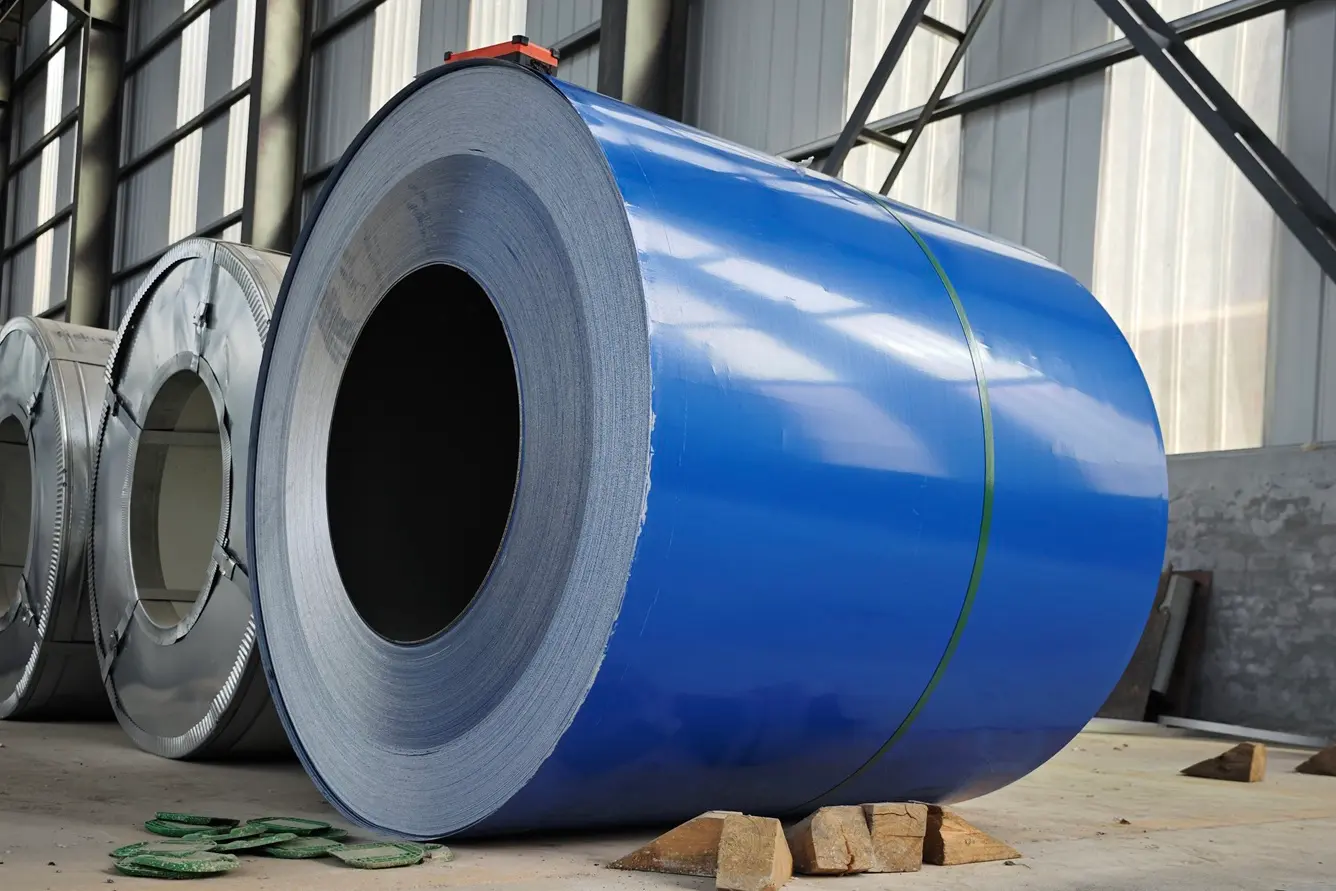

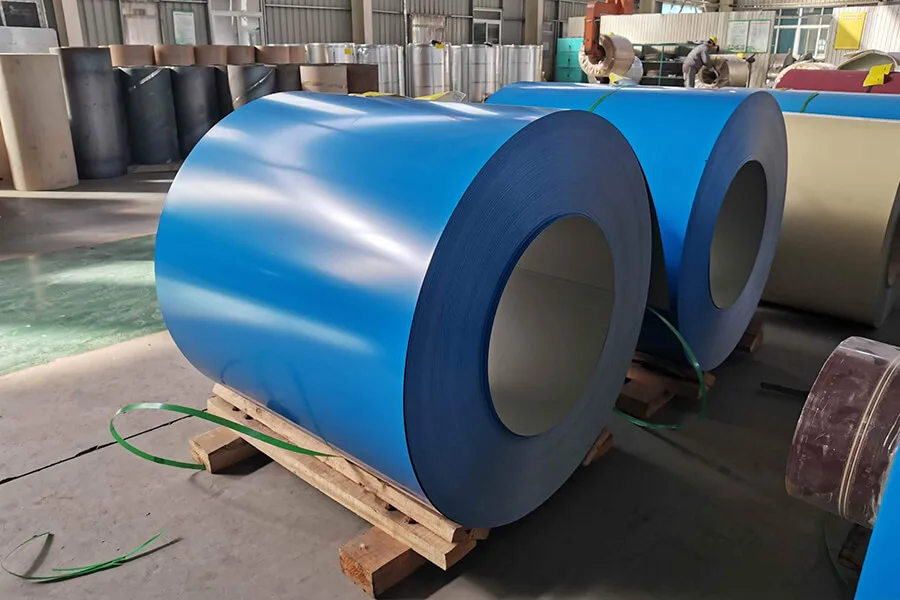

While metallic coatings provide superb corrosion resistance, many applications demand color, enhanced UV resistance, and specific textures. This is achieved through the coil coating process, which produces pre-painted steel coils.

A color steel coil is a general term for a metallic-coated coil (either galvanized or Galvalume) that has undergone a continuous, factory-controlled process to apply layers of paint. This process is highly efficient and produces a finish of superior quality and consistency compared to post-painting fabricated parts.

A prepainted galvanized steel coil, commonly abbreviated as PPGI, uses a galvanized coil as its base substrate. The zinc-coated steel is cleaned, pre-treated, and then coated with a primer and a topcoat of paint (like Polyester, SMP, or PVDF) before being cured in an oven.

PPGI is a versatile and cost-effective workhorse. It combines the excellent sacrificial protection of zinc with the aesthetic and added barrier protection of paint. It is widely used for:

- Interior panels and partitions

- Garage doors

- Basic roofing and siding for sheds and agricultural buildings

- Home appliance casings (e.g., the side panels of a refrigerator)

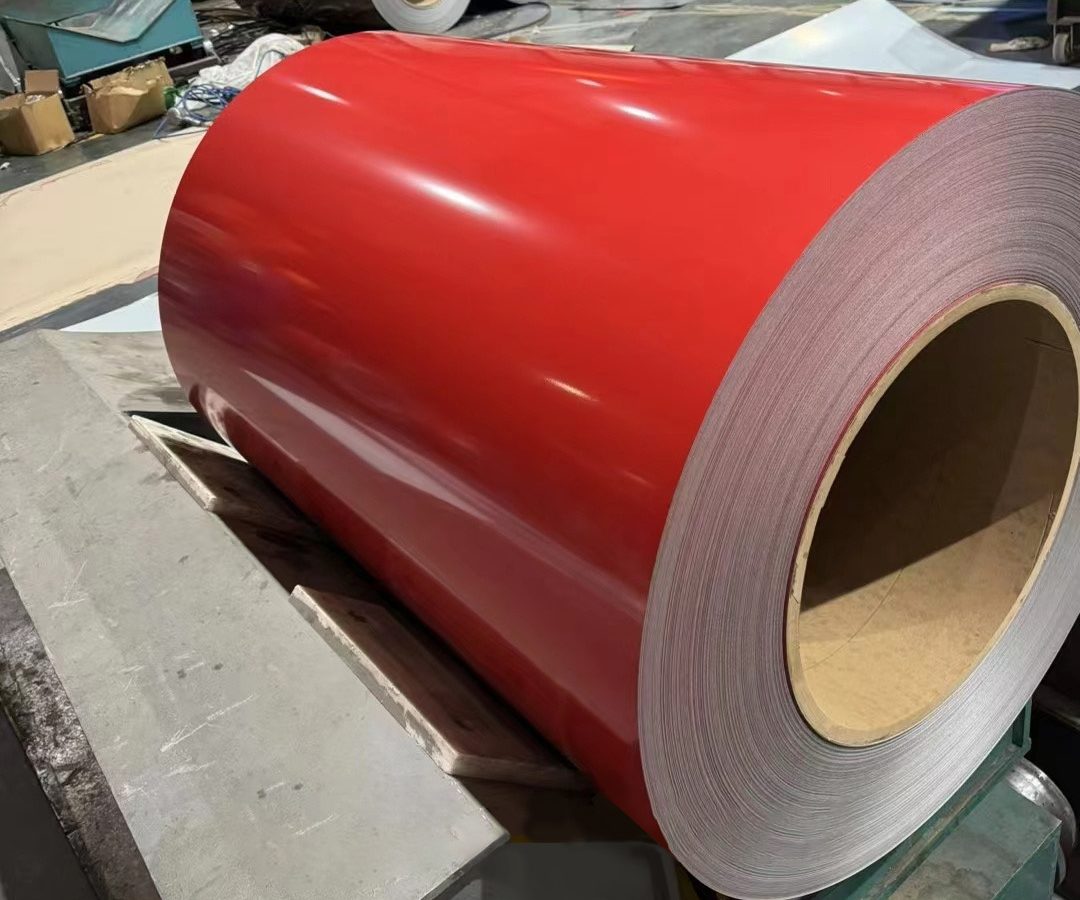

As the name suggests, pre painted galvalume steel coils (PPGL) use a Galvalume coil as the substrate. The process is identical to that of PPGI, but the final product benefits from the superior underlying corrosion resistance of the aluminum-zinc alloy.

PPGL is considered a premium product. The combination of the long-lasting Galvalume coating and a high-performance paint system (often PVDF) creates a material with an exceptionally long service life, outstanding color retention, and extensive warranties, often exceeding 30-40 years. PPGL is the material of choice for:

- High-end architectural standing seam metal roofs

- Curtain walls and exterior building facades

- Industrial and commercial building cladding

- Environments with high UV exposure or where long-term aesthetic appeal is critical.

Navigating Global Trade: Understanding HS Codes

For any business involved in the import or export of steel, understanding the Harmonized System (HS) Code is not just important—it is essential. The HS Code is an international standardized system of names and numbers to classify traded products. Customs authorities use it to apply duties, tariffs, and taxes. Assigning the correct code is crucial for legal compliance and accurate costing.

Here are the primary HS codes for the products we’ve discussed.

-

Galvanized Steel Coil HS Code

Flat-rolled products of iron or non-alloy steel coated with zinc fall under heading 7210. The most common classification is:

- HS Code: 7210.49

- Chapter 72: Iron and Steel

- Heading 7210: Flat-rolled products of iron or non-alloy steel such as clad, plated or coated.

- Subheading 7210.4: Otherwise plated or coated with zinc.

- Subheading 7210.49: — Other (This is a catch-all for various thicknesses and types not specified elsewhere).

-

Galvalume Steel Coil HS Code

The HS system has a specific classification for aluminum-zinc alloys, making it distinct from standard galvanized products.

- HS Code: 7210.61

- Chapter 72: Iron and Steel

- Heading 7210: Flat-rolled products of iron or non-alloy steel such as clad, plated or coated.

- Subheading 7210.6: Plated or coated with aluminium-zinc alloys.

- Subheading 7210.61: — Plated or coated with aluminium-zinc alloys.

Prepainted Galvanized/Galvalume Steel Coil HS Code

Once paint is the defining characteristic, the classification changes, regardless of whether the substrate is GI or GL.

- HS Code: 7210.70

- Chapter 72: Iron and Steel

- Heading 7210: Flat-rolled products of iron or non-alloy steel… clad, plated or coated.

- Subheading 7210.70: — Painted, varnished or coated with plastics.

Disclaimer: While these are the most common HS codes, specific classifications can vary based on steel thickness, width, and the regulations of the importing/exporting country. Always consult with a customs broker or the official tariff schedule for definitive classification.

Why HS Codes Matter for Steel Coil Customers

When a company imports products such as galvanized steel sheet in coil or pre painted galvalume steel coils, customs officials require precise HS codes to:

- Determine tariffs and import duties.

- Ensure compliance with safety/environmental standards.

- Track global trade statistics.

Using the wrong HS code can result in shipment delays, fines, or overpayment of duties. Therefore, when importing galvanized steel coil HS code or galvalume steel coil HS code items, importers should always consult both the supplier’s documentation and the destination country’s customs requirements.

Conclusion

The journey from a raw steel coil to a vibrant, durable finished product is a testament to modern material science. Understanding the distinctions between these advanced materials is key to ensuring the success and longevity of any project.

Understanding their differences, benefits, and especially their HS codes (like the galvanized steel coil HS code and galvalume steel coil HS code) is vital for making informed purchasing and import-export decisions.

As demand continues to grow globally, the integration of durability, aesthetics, and sustainability will keep these steel coil products at the forefront of industrial and architectural applications.

Qingdao Witop Steel group is to create value with our customers, improving competitiveness and productivity together. Through a highly efficient technological and industrial base in China and a global commercial network, we are committed to establishing a long-term cooperation with the customer. The group mainly produce cold rolled steel, hot dipped galvanized steel, hot dipped galvalume steel, pre-painted/color coated steel, tinplate, color stone coated roof tile and other steel materials.