Color coated coil are divided into indoor panels and outdoor panels.

The different surface coatings of the two types of color coated steel plates determine their suitability for different occasions. The surface of indoor panels is generally coated with resin, which cannot adapt to the harsh natural environment outdoors. If used outdoors, it will naturally accelerate its aging process, leading to discoloration and discoloration. The surface coating of outdoor color coated sheet is generally made of anti aging and UV resistant polyfluoroethylene elastomeric grease, which is expensive.

Surface scratches. Surface scratches are a type of surface defect in the production process of color coated plate, which not only affects the appearance of color coated products, but also reduces the corrosion resistance of color coated products with scratches. According to the source, it can be divided into raw material scratches and production process scratches.

Scratches on the surface of raw materials. It refers to the quality defects generated by the substrate during the galvanizing production process. When using scratch substrates to produce color coated coil, the surface of the color coated coils is prone to color differences or even missed coatings. The control measure is to check the production quality in the process and prevent scratches on the raw material substrate.

Holiday coating. Holiday coating refers to quality defects caused by the unpainted steel plate during the production process of color coated plates. Miscoating is one of the common product quality defects in the production of color coated plates. It not only directly affects the appearance of color coated products, but also affects the performance of color coated products. It will also reduce the corrosion resistance of color coated board products and lose the characteristics of color coated products. Therefore, we fully understand the reasons for missed coatings during the production process and take effective measures to prevent and control missed coating defects.

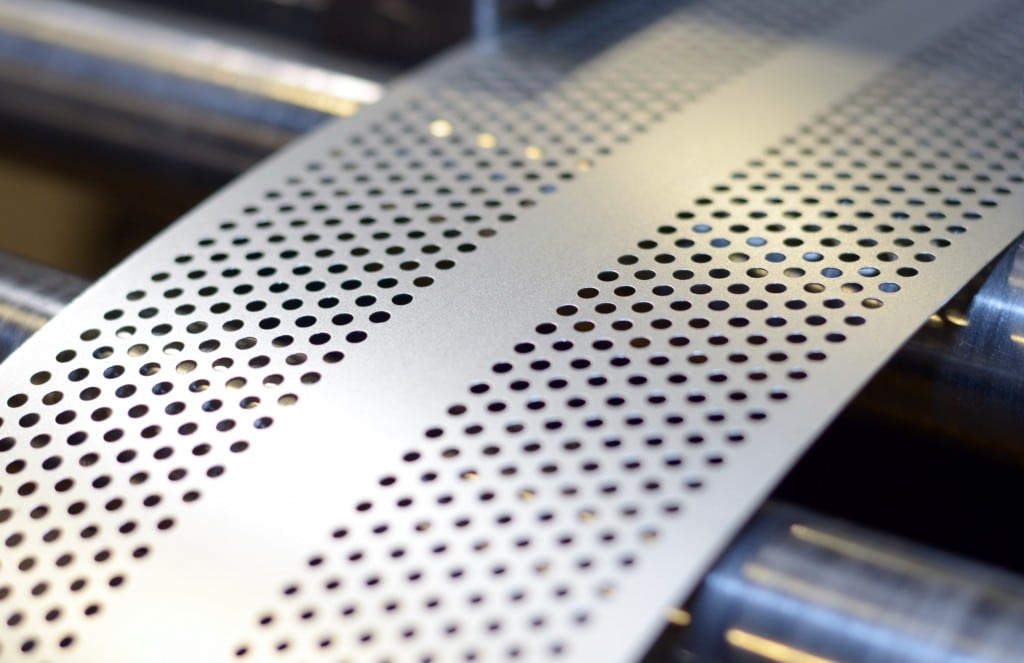

During high-temperature transportation, place desiccant in the middle of each color coated plate, or open small holes on both sides for ventilation, or place an exhaust system to avoid surface oxidation caused by encountering high-temperature water droplets during transportation.

There are many problems encountered during the production and transportation of color coated sheet. As long as these issues are resolved, the complete performance of the color coated roll can be maintained and safely delivered to the customer.