1. Process of color coated steel sheet

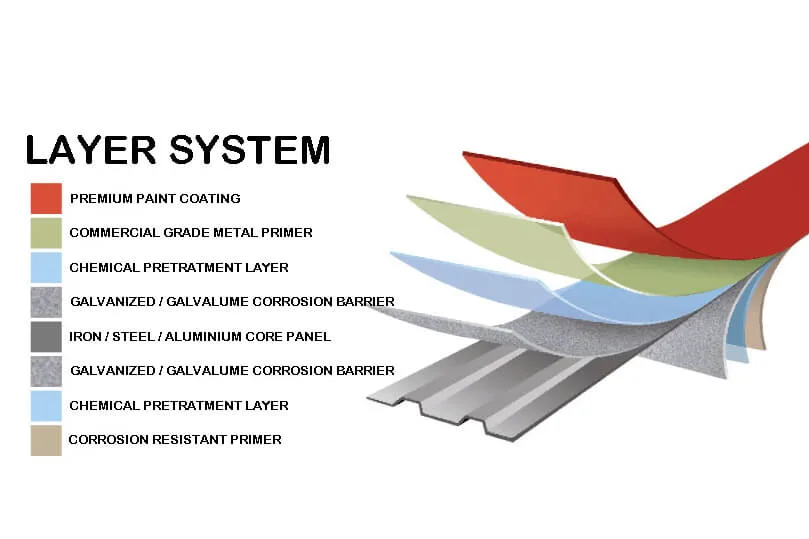

Color coated steel sheet is made from cold-rolled steel plate and galvanized steel plate as the substrate, after continuous surface pre-treatment, and then baked and cooled. The main production processes of the general process are: uncoiling – pre-treatment – coating – baking – post processing – coiling.

2. Application of Color Coated Steel Sheet

Coated steel plates are lightweight, aesthetically pleasing, and have good corrosion resistance. They can also be directly processed. Colored coated plates provide a new raw material for industries such as construction, shipbuilding, automotive manufacturing, furniture industry, and power industry, playing a good role in replacing wood with steel, conserving energy, and preventing pollution.

The organic coating on the color coated plate using galvanized steel plate as the substrate, in addition to the protective layer of zinc, plays a covering and isolation role, can prevent steel plate corrosion, and has a longer service time than galvanized steel plate.

However, the usage time of color coated plates with the same amount of galvanizing, type of coating, and thickness of coating varies greatly depending on different regions and purposes. Taking industrial areas or coastal areas as an example, their service life may be affected due to accelerated corrosion caused by the action of sulfur dioxide gas or salt in the atmosphere. Places that have been soaked in rain for a long time or have a large temperature difference during the day are prone to corrosion of the coating during the rainy season, resulting in a decrease in its service life.

Buildings or factories made of color coated sheets often suffer from rainwater erosion and have a longer service life. Otherwise, they are affected by dust due to the action of sulfur dioxide gas and salt. So when designing, the larger the inclination of the roof, the less likely it is to accumulate dust and other pollutants, and the longer the use time; For areas that are not frequently washed by rainwater, or some parts, regular water flushing should be carried out.