Have you ever stood in front of a stack of color steel coils and wondered which one really fits your construction needs? You want a product that looks good and lasts, but picking the right coil can feel tricky. Many people run into issues like surface scratches or coatings that just do not hold up outdoors. Take a quick look at some common challenges:

| Challenge | What It Means for You |

|---|---|

| Quality Issues | Defects can lower both appearance and corrosion resistance. |

| Surface Defects | Scratches hurt both the look and the lifespan of your panels. |

| Suitability for Environments | Indoor panels often fail outdoors, leading to fast aging and fading. |

To make the best choice, you need advice that balances technical details with practical tips. Focus on what matters most for your project, and you will find a coil that fits your goals.

Key Takeaways

- Consider your local environment when choosing color steel coils. Factors like humidity and temperature affect durability.

- Select colors that match your personal taste and the surrounding area. This enhances the aesthetic appeal of your project.

- Check performance metrics like coating thickness and corrosion resistance to ensure long-lasting steel.

- Inspect the substrate type for quality. Different substrates offer varying levels of durability and corrosion resistance.

- Evaluate the manufacturing quality by checking coil edges and surface finishes for defects.

- Use simple tests like sound and visual inspections to assess the quality of steel coils before purchase.

- Choose a reliable supplier with good reviews and necessary certifications to ensure you receive high-quality materials.

- Balance cost and quality when purchasing. Investing in better materials can save money on repairs in the long run.

Project Requirements

When you start planning construction projects, you need to think about what your project really needs. Picking the right color steel coils means looking at your environment, the look you want, and how the material will perform over time. Let’s break down these three key areas so you can make smart choices for your structural steel needs.

Environment

Your local environment plays a huge role in how well steel will last. You want your structural steel to stand up to whatever nature throws at it. Here are some things to keep in mind:

- Humidity and temperature can change how steel performs. If you live near the coast, salt in the air can cause rust. You should choose coatings with strong corrosion resistance for these areas.

- In places with big temperature swings, pick colors that can handle thermal stress. Some colors fade or crack when the weather changes fast.

- Lighter colors reflect sunlight and heat. This helps keep buildings cooler in hot climates and can save energy.

If you match your color steel coils to your environment, your construction projects will last longer and look better.

Aesthetics

You want your building to look good and fit in with its surroundings. The color you choose for your structural steel can make a big difference. Here’s what you should think about:

- Pick a color that matches your personal taste. You’ll enjoy your project more if you like how it looks.

- Look at the colors around your site. Choose shades that blend well and avoid finishes that glare in the sun.

- Think about your building’s style. Some colors work better with modern designs, while others fit classic looks.

- If your project represents a brand, use colors that show off your company’s identity.

- Local climate matters too. Some colors hold up better in certain weather.

Choosing the right color for your steel helps your construction stand out and feel right for the area.

Performance

You want your structural steel to do its job for years. Performance matters just as much as looks. Here’s a quick table to help you check what’s important:

| Performance Metric | Description |

|---|---|

| Coating Thickness | Measures how thick the protective layer is on the steel. |

| Hardness | Shows how well the steel resists scratches and dents. |

| Flexibility | Tells you if the steel can bend without cracking. |

| Adhesion | Checks if the coating sticks well to the steel surface. |

| Impact Resistance | Measures how much force the steel can take before breaking. |

| Corrosion Resistance | Shows how well the steel fights rust and damage in tough environments. |

| Anti-aging Performance | Tells you how long the coating will last under different weather conditions. |

| Appearance Tests | Looks for defects and checks if the color is even across the surface. |

If you check these performance metrics, you’ll know your color steel coils will hold up in your construction projects. You want steel that looks good, lasts long, and fits your needs.

Color Steel Coils: Material Quality

When you want your building to last, you need to pay close attention to the material quality of your color steel coils. The right choice gives you strong, long-lasting results. Let’s look at what matters most.

Substrate Types

The substrate is the base metal under the coating. It decides how your color steel plates will perform in different environments. You have several options, and each one brings its own benefits.

| Substrate Type | Application Area | Quality Impact |

|---|---|---|

| Hot dipped galvanized steel | Outdoor uses | High corrosion resistance |

| Galvalume | Building materials | Excellent durability and aesthetic appeal |

| Zinc alloy | Various applications | Enhanced mechanical properties |

| Cold rolled steel | Indoor uses | Good surface finish and strength |

| Aluminum | Decorative materials | Lightweight and corrosion resistant |

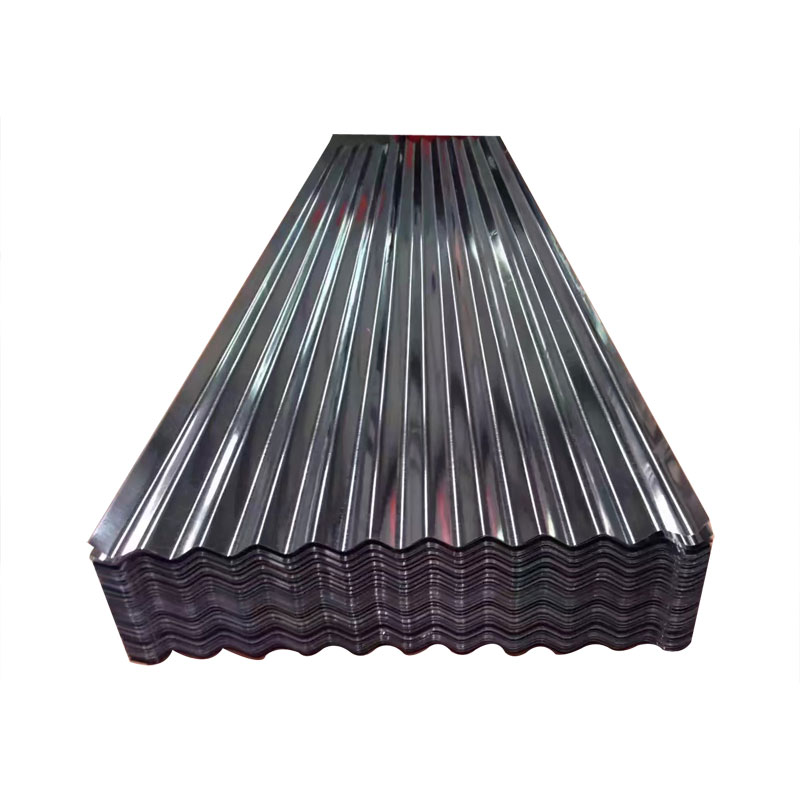

Galvanized

You see galvanized steel used in many outdoor projects. The zinc coating protects the steel from rust and boosts its strength. This type works well if you want high corrosion resistance and need your structural steel to last in tough weather.

Galvannealed

Galvannealed steel goes through an extra process that makes the zinc coating harder. This gives you better paint adhesion and more durability. If you want color steel plates that hold up to scratches and dents, this is a smart pick.

Tip: Always check the substrate type before you buy. The right base metal helps you meet your project’s strength and durability needs.

Film Thickness

The film thickness is the layer of paint or coating on your color steel plates. This layer protects the steel and keeps it looking good. Thicker coatings usually mean longer life and better resistance to weather.

- Thicker film gives you a longer aesthetic lifespan.

- It also extends the service life of your structural steel.

- The right film thickness helps your building stand up to rain, sun, and pollution.

Here’s a quick look at how film thickness affects corrosion resistance:

| Coating Type | Film Thickness (μm) | Corrosion Resistance Duration |

|---|---|---|

| SMP | 20-22 | 10-12 years |

| PE | 20-22 | 7-8 years |

If you want your color steel plates to last, always ask about the coating thickness. It’s a key part of quality structural steel grades.

Durability

You want your building to stay strong for years. Durability depends on both the substrate and the coating. When you choose high-quality structural steel grades, you get better strength and longer life.

Here are some ways you can check durability:

- Look for mechanical strength. Good color steel plates should not bend or break easily.

- Check for corrosion resistance. Ask your supplier about the results of salt spray or weathering tests.

- Make sure the steel meets industry standards for size, coating, and surface inspection. For example, width error should be within ±2mm, and the surface should be flat with no major defects.

| Test Type | Purpose |

|---|---|

| Mechanical Property Testing | Evaluates yield strength, tensile strength, elongation, and hardness. |

| Non-Destructive Testing (NDT) | Inspects for uniformity and defects without damaging the material. |

| Bend and Rebend Testing | Assesses flexibility and crack resistance after bending. |

Note: If you want the best results, always choose color steel plates that pass strict quality checks. This helps you avoid problems like rust, fading, or weak spots in your structural steel.

When you focus on substrate, film thickness, and durability, you get color steel coils that meet your needs and last for years. You also make sure your project uses only the best quality structural steel grades.

Color Steel Plates: Manufacturing Quality

When you want your construction project to stand out, you need to pay close attention to the manufacturing quality of your color steel plates. High-quality plates help your structural steel last longer and look better. Let’s walk through the main things you should check before you buy.

Coil Edges

Start by inspecting the coil edges. You can spot many problems just by looking closely. Uneven edges or strange curves can mean trouble for your structural steel. Here’s a quick checklist to guide you:

- Inspect for oil canning. This looks like visible waviness along the edge.

- Check for smooth edges. Rough or jagged edges can lead to rust and weak spots.

- Look for mushrooming. Warped or uneven edges can make installation harder.

You might also notice defects like coil break, crossbow, or surface imperfections. These issues can affect both the appearance and the strength of your color steel plates.

| Defect Type | Description |

|---|---|

| Coil Break | Narrow, irregular deformation lines on low carbon steel strips. |

| Crossbow | Uneven coil edge alignment and curvature along the coil length. |

| Surface Imperfections | Includes waviness, roughness, and oil canning. |

Tip: Always run your hand along the coil edge. If you feel bumps or see curves, ask your supplier for a better batch.

Surface Finish

The surface finish of your color steel plates matters for both looks and performance. A smooth finish helps your structural steel resist wear and tear. It also makes your building look sharp.

- The finish you choose—matte, gloss, or patterned—changes how light reflects off the steel.

- A brushed finish can hide scratches and fingerprints, which keeps your project looking fresh.

Check the roughness of the surface. Smoother finishes (Ra roughness 3.2 micrometers or less) boost wear resistance by up to 40%. If the surface feels rough or looks uneven, the steel may not last as long.

| Surface Finish | Ra Roughness (micrometers) | Wear Resistance Increase |

|---|---|---|

| Smoother | 3.2 or less | 40% |

| Rougher | Greater than 3.2 | N/A |

Note: Good surface finish means fewer repairs and less maintenance for your structural steel.

Uniformity

Uniformity is key for quality color steel plates. You want every section of your steel to look and perform the same. Here’s how you can check for uniformity:

- Use pattern recognition to spot blobs, bubbles, or discoloration.

- Try contrast enhancement to highlight subtle defects.

- Real-time analysis helps you catch problems fast.

- Defect classification sorts issues by size and severity.

- High-resolution cameras and advanced lighting show you every detail.

- AI-powered systems can give you a full report on defects.

- Conveyor and motion control keep inspections consistent.

| Inspection Method | Description |

|---|---|

| Pattern Recognition | Identifies normal patterns and flags deviations such as blobs, bubbles, or discoloration. |

| Contrast Enhancement | Adjusts image contrast to highlight subtle defects on light or dark surfaces. |

| Real-Time Analysis | Processes images instantly, enabling immediate defect detection and corrective actions. |

| Defect Classification | Categorizes defects based on size, type, and severity for actionable insights. |

| High-Resolution Cameras | Includes line-scan and area-scan cameras for different inspection scenarios. |

| Advanced Lighting Solutions | Utilizes various lighting techniques tailored to the color and finish of the coated metal. |

| AI-Powered Defect Detection | Employs AI algorithms for comprehensive defect analysis and reporting. |

| Conveyor and Motion Control | Ensures consistent imaging through uniform speed and synchronization of systems. |

If you check coil edges, surface finish, and uniformity, you’ll get color steel coils and plates that meet your project’s needs. Your structural steel will look great and stay strong for years.

Quality Testing

When you want to make sure your color steel coils are up to the task, you need to check their quality before you start building. You do not need fancy equipment for some of these tests. You can use your senses and a few simple tricks to spot problems early. Let’s look at two easy ways to test your coils right on site.

Sound Test

The sound test is a classic trick that many pros use. You can do it in seconds, and it tells you a lot about the steel’s quality. Here’s how you do it:

- Hold a small piece of the color steel coil or gently tap the coil with a metal object.

- Listen closely to the sound it makes.

What should you hear? Good quality steel gives off a crisp, clear, and ringing sound. If you hear a dull, muffled, or flat noise, that could mean the steel has internal cracks, hidden rust, or uneven thickness.

Tip: Try tapping a few different coils and compare the sounds. You’ll quickly notice which ones stand out as strong and which ones might have issues.

Here’s a quick table to help you remember what the sounds mean:

| Sound Type | What It Means |

|---|---|

| Clear & ringing | High quality, solid steel |

| Dull or flat | Possible defects or hidden problems |

| Rattling | Loose layers or poor bonding |

You do not need to be an expert to use this test. Trust your ears. If something sounds off, ask your supplier for another coil.

On-Site Checks

Besides the sound test, you can do a few more quick checks right where you store or receive your coils. These tests help you spot problems before they turn into bigger headaches.

- Visual Inspection: Look for dents, scratches, rust spots, or uneven color. Good coils should have a smooth, even surface with no visible damage.

- Touch Test: Run your hand along the coil. You should feel a smooth, even texture. Bumps or rough patches can mean poor manufacturing.

- Flex Test: Gently bend a small corner of the coil. Quality steel bends slightly without cracking or flaking. If the coating chips or the steel feels brittle, it may not last long.

- Thickness Check: Use a simple caliper or thickness gauge. Make sure the coil matches the thickness your project needs.

Note: Always check a few coils from each batch. Sometimes, problems only show up in certain pieces.

If you use these simple tests, you can catch most quality issues before they cause trouble. You save time, money, and stress by making sure your color steel coils are ready for the job.

Supplier Selection

Choosing the right supplier for your color steel coils can make or break your project. You want steel that meets all standards and lasts for years. Let’s look at how you can spot a reliable structural steel supplier and make sure you get the best value.

Reliability

You need a supplier who delivers on promises. Reliable suppliers always meet deadlines and provide steel that matches your standards. You can check reliability by looking at several key indicators. Here’s a table to help you compare:

| Indicator | Description |

|---|---|

| Material Quality | Check if the steel substrate and paint system meet recognized standards. |

| Coating Technology | See if the supplier offers a range of paint systems with strong performance. |

| Certifications | Make sure the supplier follows quality management systems like ISO 9001. |

| Quality Assurance | Ask about internal QA practices and testing for product reliability. |

| Customization | Look for suppliers who offer services tailored to your project needs. |

| Processing Capabilities | Find out if they have in-house services to streamline production and reduce waste. |

| Supplier Reputation | Read reviews and testimonials to see how others rate their reliability and customer service. |

| Logistical Strength | Check if the supplier can handle delivery schedules and supply chain challenges. |

If you want your steel to last, always choose a reliable structural steel supplier who meets these standards. You’ll avoid delays and get color steel plates that fit your project.

Certificates

Certifications prove that your supplier follows strict standards. You should always ask for certificates before you buy steel. These documents show that the color steel plate manufacturers meet industry requirements and produce safe, high-quality products. Here are some important certifications to look for:

- ISO9001 quality and management system certification

- PVOC certification

- SGS testing certificate

- BV testing certificate

You can also request:

- MTC (Material Certificate)

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Protection)

Tip: Suppliers with these certifications show they care about quality and safety. You can trust their steel to meet your standards.

Reputation

A supplier’s reputation tells you a lot about their business. You want to work with color steel plate manufacturers who have a strong track record. Check online reviews and ask for testimonials from past customers. Reliable suppliers often have positive feedback and repeat clients. You can also look for awards or industry recognition.

If you see complaints about missed deadlines or poor steel quality, keep searching. A reliable structural steel supplier will always put your needs first and follow strict standards. You deserve steel that meets every requirement and lasts for years.

Note: Good reputation means fewer headaches and better results for your project.

Cost Evaluation

Choosing color steel coils for your construction projects means you need to think about more than just the sticker price. You want to get the best value for your money, but you also want steel that will last and look good. Let’s break down how you can balance cost and quality, plan your budget, and get the best deal from your suppliers.

Price vs. Quality

You might feel tempted to pick the lowest price, but that can lead to problems later. When you compare steel options for your projects, look at both the price and the quality. Here’s how you can find the right balance:

- Galvanized steel gives you strong corrosion resistance. It lasts longer in tough environments, so you may save money on repairs.

- Color-coated steel keeps its color and looks sharp for years, but only if the coating is high quality.

- Both types need regular care to stay in top shape.

You should also pay attention to the coating. A thicker layer of paint not only looks better but also protects the steel for a longer time. If you invest in higher-quality materials, you might spend more at first, but you will save on maintenance and replacement costs as your construction projects age.

Tip: Don’t just look at the price tag. Think about how much you will spend over the life of your projects.

Budgeting

Smart budgeting helps you avoid surprises and keeps your construction on track. Here are some strategies you can use when planning for steel purchases:

- Set up long-term contracts with your suppliers. This can help you lock in a stable price.

- Work with more than one supplier. If one has a problem, you have other options.

- Add a little extra to your budget for price changes. Steel prices can go up and down.

- Watch the market. If you know what’s happening with steel prices around the world, you can make better choices.

- Some companies use financial tools to protect against price jumps.

- Try value engineering. Look for ways to save money without lowering the quality of your steel.

- Talk openly with your suppliers. Good communication can help you get better deals when prices rise.

If you follow these steps, you can keep your construction projects running smoothly, even if the market changes.

Negotiation

Getting the best price for your steel takes more than just asking for a discount. You need to use smart negotiation tactics. Here are some ways you can save money:

- Build strong relationships with your suppliers. They may offer you better prices and flexible terms.

- Learn how suppliers set their prices. This helps you know where you can ask for savings.

- Order in bulk when you can. Larger orders often come with bigger discounts.

- Ask for a detailed breakdown of costs. This gives you more power to negotiate.

- Always compare quotes from different suppliers. This helps you spot the best deal.

Note: Good negotiation can lower your costs and help you get higher-quality steel for your construction projects.

If you balance price and quality, plan your budget, and negotiate well, you will get the most value from your steel purchases. Your projects will stay on budget and your buildings will stand strong for years.

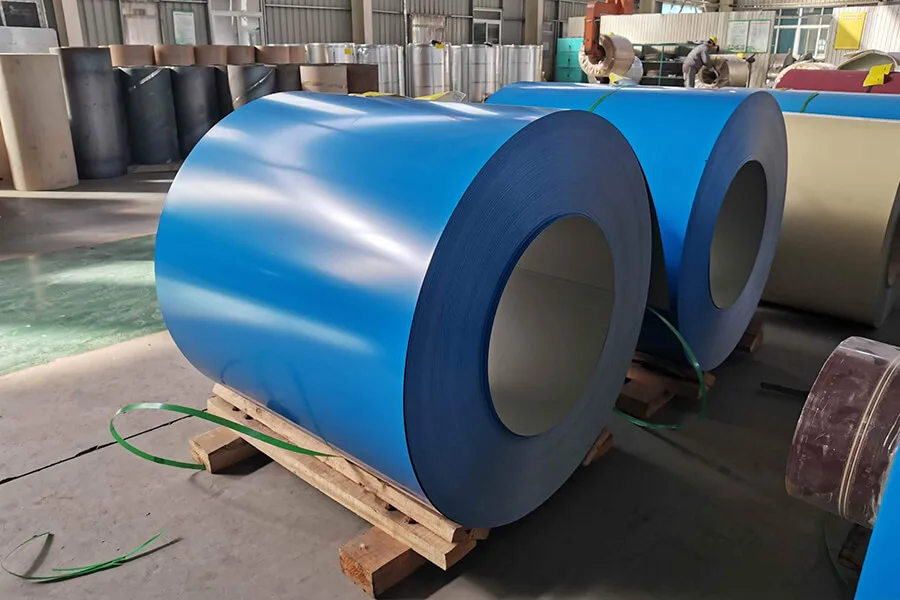

Color Selection

Choosing the right color for your steel coils can make your building stand out and last longer. You have many options, but a smart choice starts with understanding how colors work together, how your local climate affects your decision, and what custom finishes are available.

Color Wheel

You do not need to be an artist to use a color wheel. This simple tool helps you pick colors that look great together. If you want your steel panels to blend in, choose colors next to each other on the wheel. These are called analogous colors. For a bold look, pick colors from opposite sides. These are complementary colors and create strong contrast.

- Want a calm, modern feel? Try blues and grays.

- Looking for something lively? Pair green with red or orange with blue.

- For company branding, match your steel color to your logo or theme.

A color wheel can help you avoid clashing shades and create a building that feels balanced. You can even ask your supplier for a sample chart to see how different colors look on steel.

Climate Impact

Your local climate should guide your color choice. Some colors work better in certain weather. Here’s a quick table to help you decide:

| Climate Condition | Recommended Color | Reason for Selection |

|---|---|---|

| Hot and Humid Areas | Lighter Colors | Reflect more sunlight, keeping the structure cooler. |

| Colder Locations | Darker Colors | Absorb more sunlight, helping to keep the building warmer. |

| General Energy Efficiency | Lighter Colors | More energy-efficient due to reduced cooling needs. |

| Darker Colors | Can increase energy costs due to higher heating needs. |

If you live in a hot place, lighter colors on your steel will reflect sunlight and help keep your building cool. In cold areas, darker colors can help your steel absorb heat and lower your heating bills. Always think about how the weather will affect your color choice.

Tip: Lighter colors often last longer in sunny climates because they fade less.

Customization

You have more choices than ever when it comes to customizing your steel coils. Manufacturers offer a wide range of colors, finishes, and textures. You can pick from smooth, matte, or even woodgrain finishes. Some steel coils come with special coatings that add extra shine or protect against scratches.

Here are some popular options:

- Trim Coil: Pebble texture, painted finish, aluminum base.

- TruCoil® PVC: Embossed woodgrain, Q800 TuffTech coating, aluminum.

- IsoCoil®: Smooth matte finish, Q800 TuffTech, aluminum.

- Vesta Trim Coil: Smooth matte finish, Kynar 500® coating, steel.

- TruCedar® Trim Coil: Embossed woodgrain, Kynar® coating, steel.

- System Colors: Many shades like Evening Shade, Norwood, and more.

- Decorative Patterns: Choose from gold titanium, rose gold, sapphire blue, and other unique looks.

Sanmei Metal and other suppliers use advanced technology to create vibrant, durable colors on steel. You can even request custom shades to match your brand or design vision.

Note: Always ask your supplier about available finishes and color samples before you order. This helps you get the exact look you want for your steel project.

Final Tips

Checklist

Before you make your final decision on color steel coils, it helps to have a clear checklist. This way, you can make sure you do not miss any important steps. Here is a simple table you can use when you inspect your coils:

| Item Type | Inspection Criteria |

|---|---|

| Weight Check | Calibrate your scale and count each piece for accuracy. |

| Dimension Check | Confirm thickness, width, and diameter match your project’s needs. |

| Visual Inspection | Look for dents, scratches, or uneven welds on the surface. |

| Mill Test Certificate | Ask for the MTC to verify the steel’s origin and quality. |

| Chemical Composition Test | Use a spectrometer to check the steel’s chemical makeup. |

| Mechanical Property Test | Test for yield strength, tensile strength, and elongation. |

| Hardness Test | Check how well the steel resists dents and scratches. |

| Ultrasonic Testing | Scan for hidden flaws inside the steel material. |

You can print this checklist and bring it with you when you visit suppliers. It will help you stay organized and confident during your evaluation.

Mistakes

Everyone makes mistakes, but you can avoid the most common ones if you know what to watch for. Here are some pitfalls that often trip up buyers:

- Missed Coating: Sometimes the coating does not cover the steel evenly. This leaves the metal exposed and more likely to rust.

- Color Difference: You might see color changes between different batches or coils. This can make your building look patchy.

- Skipping the Maintenance: If you do not clean and care for your coils, dirt and grime will build up. This shortens their lifespan.

- Ignoring Environmental Factors: Always think about where you will use the coils. Coastal areas need extra corrosion resistance.

If you keep these mistakes in mind, you will save time and money. You will also get better results for your project.

Expert Advice

Sometimes, you need more than just a checklist. That is when expert advice becomes valuable. An expert can spot issues you might miss and help you choose the best color steel coils for your needs. You can ask an expert about the right substrate, coating, or even the best supplier in your area. Many experts have years of experience and know the latest trends in steel technology.

If you feel unsure, do not hesitate to reach out for expert advice. You can talk to a trusted supplier, a construction engineer, or a materials specialist. Their expert advice can help you avoid costly mistakes and get the most value from your purchase. Remember, even the best DIY research cannot replace the insights of an expert who has seen it all.

Tip: When in doubt, always seek expert advice. It can make the difference between a good project and a great one.

You can make smart choices for your construction project by following these steps:

- Check the thickness of both substrate and coating for your color steel coils.

- Inspect the plate’s edge for crystal density and impurities.

- Tap the plate and listen for a clear metallic sound.

- Ask for quality certificates and inspection standards.

- Compare price with product quality.

High-quality color steel coils give you better corrosion resistance and a great look. Durable color options mean less maintenance and longer life. Value comes from balancing cost and long-term performance. Use this advice to pick the right color and feel confident in your decision. Got questions or want to share your experience? Drop a comment below!

FAQ

What is the best way to store color steel coils before installation?

Keep your coils in a dry, covered area. Place them on wooden pallets or racks. Make sure air can flow around them. Avoid direct contact with the ground or water. This helps prevent rust and keeps your steel in top shape.

How do I know if a color steel coil is high quality?

Check for a smooth surface, even color, and no dents or scratches. Tap the coil and listen for a clear, ringing sound. Ask your supplier for quality certificates. Trust your senses and always inspect a few coils from each batch.

Can I use the same color steel coil for both indoor and outdoor projects?

You should not. Outdoor projects need coils with stronger coatings and better corrosion resistance. Indoor coils may not last outside. Always match the coil type to your project’s environment for the best results.

What should I do if I find defects after delivery?

Contact your supplier right away. Take clear photos of the defects. Keep the coils in their original packaging if possible. Most reliable suppliers will help you solve the problem quickly.

How do I choose the right color for my project?

Use a color wheel to find shades that match your style or brand. Think about your local climate. Lighter colors work well in hot areas. Darker shades suit colder places. Ask for samples to see how colors look in real light.

Do I need special tools to test color steel coils quality?

You do not need fancy tools. A simple caliper checks thickness. Your eyes and hands help spot surface issues. Tapping the coil tests sound. For deeper checks, ask your supplier for test reports or certificates.

How often should I maintain color steel coils after installation?

Inspect your steel at least once a year. Clean off dirt and debris. Check for scratches or rust spots. Quick fixes help your steel last longer and keep it looking great.

Can I customize the finish or texture of my color steel coils?

Yes! Many suppliers offer custom finishes like matte, gloss, or woodgrain. You can also pick special coatings for extra protection. Just ask your supplier about available options and samples.