Introduction

In the world of construction, manufacturing, and fabrication, galvanized steel has earned a strong reputation for its lastingness, corrosion resistance, and versatility. Whether you’re working on roofing, walling, automotive components, HVAC systems, or fencing, products like galvanized sheet metal rolls, hot dipped galvanized steel coils, galvanized metal strips, and GI sheet rolls play a crucial role in getting the job done right.

In this blog post, we’ll take a deep dive into these popular materials, how they’re made, their applications, and how to choose the right type for your project.

What Is Galvanized Steel?

Galvanized steel is essentially regular carbon steel that has been coated with a protective layer of zinc. This zinc layer serves as a sacrificial barrier that prevents corrosion and rust, even if the coating gets scratched. Among the many galvanizing methods, hot-dip galvanizing is the most common and effective for industrial use.

Galvanized Sheet Metal Roll

A galvanized sheet metal roll refers to a long sheet of steel that has been coated in zinc and rolled into coils. These rolls can be cut, bent, and shaped to suit various applications, such as ducts, panels, enclosures, and chassis.

Key Features:

- Zinc-coated for corrosion resistance

- Flexible and easy to fabricate

- Available in multiple thicknesses and widths

- Compatible with welding, painting, and powder coating

Galvanized sheet metal rolls are widely used in the production of galvanized metal panels for construction and roofing. Because they can be unrolled and cut to custom lengths, they are cost-effective and reduce material wastage.

Hot Dipped Galvanized Steel Coils

Hot dipped galvanized steel coils are produced by immersing cold-rolled steel in molten zinc, which forms a strong metallurgical bond between the steel and zinc layer. This process enhances corrosion protection and increases the lifespan of the steel.

Advantages:

- Thicker zinc coating compared to electro-galvanizing

- Excellent protection against weather and moisture

- Long service life even in harsh outdoor environments

Hot dipped galvanized coils are often used for large-scale projects such as bridges, road barriers, industrial warehouses, and agricultural buildings. They’re also a go-to choice for manufacturers producing galvanized sheet rolls and galvanized strips.

Galvanized Metal Strips

Galvanized metal strips are narrow bands of galvanized steel cut from wider coils. These strips are essential in the production of electrical appliances, cable trays, roofing nails, framing components, and more.

Why Use Galvanized Strips?

- Easy to handle and install

- Uniform thickness and width

- Ideal for automated roll-forming machines

- Corrosion resistance increases lifespan in exposed applications

In the construction industry, galvanized strips are commonly used as edge trims, brackets, and framing supports. Their flexibility and strength make them perfect for reinforcing structures without adding unnecessary weight.

GI Sheet Roll (Galvanized Iron Sheet Roll)

The term GI sheet roll refers specifically to Galvanized Iron sheets that are zinc-coated to enhance durability. These rolls are often used in similar ways as general galvanized sheet metal rolls but may differ slightly in alloy composition or manufacturing standard.

GI Sheet Roll Uses:

- Roofing and wall cladding

- Ductwork and HVAC systems

- Interior partitions and false ceilings

- Rural and industrial fencing

The growing demand for GI sheet rolls in emerging markets stems from their affordability and ability to withstand monsoon conditions and high humidity, especially in coastal and tropical regions.

Galvanized Sheet Roll vs. Galvanized Metal Panels

While a galvanized sheet roll is the raw material supplied in coil form, galvanized metal panels are the finished products shaped and cut for specific applications.

Panels are commonly used in:

- Exterior and interior wall systems

- Roofing applications

- Siding and fencing

- Decorative facades

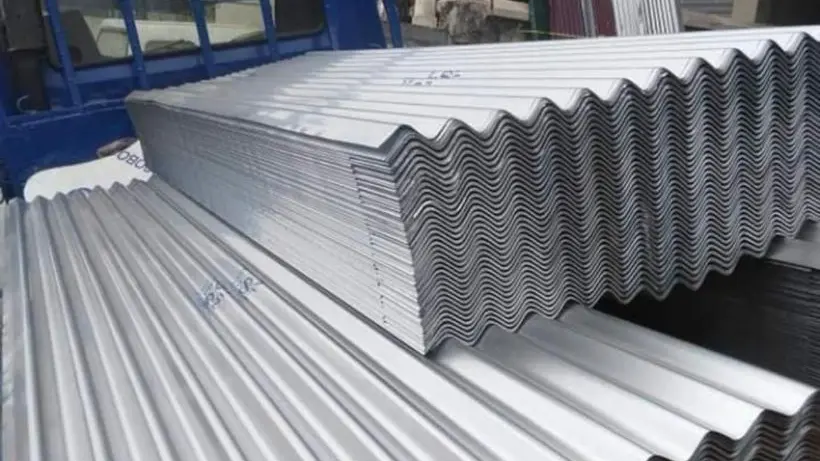

Galvanized metal panels come in various profiles like ribbed, corrugated, or flat designs. They provide both structural support and aesthetic appeal, making them popular for both residential and commercial buildings.

Benefits of Using Galvanized Products

Whether you’re using coils, strips, or panels, galvanized steel offers several unbeatable benefits:

1. Corrosion Resistance

Zinc forms a protective barrier that slows down oxidation and rust formation, even when scratched or exposed.

2. Long Service Life

Galvanized steel can last anywhere from 20 to 50 years, depending on environmental exposure.

3. Cost-Effective

Though slightly more expensive than untreated steel, the extended service life and reduced maintenance costs offer long-term savings.

4. Recyclability

Galvanized steel is 100% recyclable, making it an eco-friendly choice for green buildings and sustainable projects.

5. Low Maintenance

Unlike painted or coated metals, galvanized products require minimal upkeep, even in outdoor environments.

Industries That Rely on Galvanized Steel

Galvanized steel is a favorite in many industries due to its reliability and versatility:

- Construction: Roofing, cladding, gutters, framing

- Automotive: Body panels, chassis, bumpers

- Agriculture: Silos, fences, greenhouse frames

- Telecommunications: Towers, brackets, enclosures

- HVAC: Ducts, housing, vents

No matter the industry, galvanized steel provides a practical solution for structures that demand strength and resistance to the elements.

Choosing the Right Galvanized Product: Parameters that need to be considered

When selecting between galvanized sheet metal rolls, hot dipped galvanized steel coils, or galvanized metal strips, consider the following factors:

1. Thickness

Thicker materials offer more strength but can be harder to shape. For structural applications, choose a higher gauge.

2. Coating Thickness

Higher zinc coating (measured in GSM – grams per square meter) provides better corrosion resistance, especially for outdoor use.

3. Forming Requirements

If your application requires complex bending or forming, opt for products with high ductility.

4. Budget

While hot dipped galvanized coils offer superior protection, they may come at a higher initial cost. Balance your budget with durability requirements.

Trends in Galvanized Steel Production

With the rise of eco-conscious construction and infrastructure projects, demand for galvanized products is growing. Manufacturers are investing in new technologies to improve coating uniformity, reduce energy consumption, and meet tighter environmental regulations.

In addition, pre-painted galvanized steel (also known as PPGI) is gaining popularity for architectural applications, combining corrosion resistance with visual appeal. Galvanized steel is no longer just a utilitarian choice – it’s also a design material.

Final Thoughts

Whether you’re a builder, fabricator, architect, or DIY enthusiast, galvanized sheet metal rolls, hot dipped galvanized steel coils, galvanized metal strips, GI sheet rolls, and galvanized metal panels offer durable, economical, and flexible solutions for countless projects.

Choosing the right type of galvanized steel can improve your project’s longevity, reduce maintenance costs, and ensure long-term performance in all weather conditions. From rooftops to road signs, the applications are endless—and the advantages are hard to beat.

If you’re looking to source high-quality galvanized steel products or need help selecting the right material for your application, feel free to reach out Qingdao Witop Steel group. Our team is always at your service helping you to find your desired products. With the right product and proper installation, galvanized steel can deliver decades of dependable service.