Choosing the right metal roofing coil for your building takes more than just picking a color or finish. You need to match the coil’s specs to your project’s needs from the start. If you skip details or rush decisions, you could end up with wrong measurements, visible seams, or fasteners that rust too soon. Some people even forget about things like roof slope or use the wrong accessories, which can cause leaks or damage. Pay attention to both technical and practical factors, and you’ll avoid costly headaches later.

Key Takeaways

- Consider your location and climate when choosing a metal roofing coil. Different weather conditions require specific materials for durability.

- Check local building codes before ordering. Compliance with regulations can save you from costly rework and fines.

- Select a roofing style that matches your building’s aesthetics. The right color and finish enhance your building’s appearance without sacrificing quality.

- Plan your budget carefully. Understand the cost factors, including material type and necessary accessories, to avoid unexpected expenses.

- Choose the right metal type based on your environment. Aluminum is best for coastal areas, while steel is suitable for most other climates.

- Pay attention to coil specifications like thickness and width. These details ensure proper fit and performance during installation.

- Pick a reliable supplier with quality certifications. A trustworthy supplier provides better materials and support, reducing future repair costs.

- Double-check your order details before confirming. Accurate specifications prevent mistakes that can lead to delays and additional costs.

Project Needs

Location & Climate

Weather Resistance

Where your building stands makes a big difference in the type of metal roofing coil you should choose. You want your roof to handle whatever the weather throws at it. Here are some things to think about:

- If you live in a hot, dry place, you need a fire-resistant roof. This helps protect your building from wildfires.

- In areas with hurricanes or strong winds, your roof must meet strict wind resistance standards. This keeps your roof safe and secure during storms.

- For buildings near the coast, saltwater can cause metal to rust. Aluminum roofing works best here because it resists corrosion. Galvalume might not last as long in salty air.

You should also look at the type of metal and coating. Some coatings, like PVDF, add extra protection against harsh weather and UV rays. Thicker coatings and special finishes can help your roof last longer, especially outdoors.

Building Codes

Every city or town has its own building codes. These rules tell you what kind of roof you can use. You need to check local codes before you order your metal roofing coil. Some places require certain fire ratings or wind resistance. If you skip this step, you might have to redo your roof later. That costs time and money.

Design & Budget

Style

You want your building to look good, right? The style of your roof matters. You can pick from different colors, gloss levels, and textures. Some people choose colors that match their brand or neighborhood. Others want a certain finish to make their building stand out. The right metal roofing coil lets you get the look you want without giving up strength or weather protection.

Cost Factors

Planning your budget is just as important as picking the right material. Here’s a simple way to keep your spending on track:

- Look at your current bills and see how a new roof fits in.

- Set a spending limit that feels comfortable.

- List the must-have items, like panels and underlayment.

- Make a wish list of extras, such as special finishes or accessories.

- Pick the option that matches your budget and needs.

The cost of your roof depends on many things: panel width, paint type, profile, metal thickness, and the accessories you need (like fasteners, clips, and sealants). If you plan ahead, you can avoid surprises and get the best value for your money.

Choosing the right metal roofing coil means thinking about where you live, what your building needs, and how much you want to spend. Take your time, ask questions, and you’ll end up with a roof that lasts.

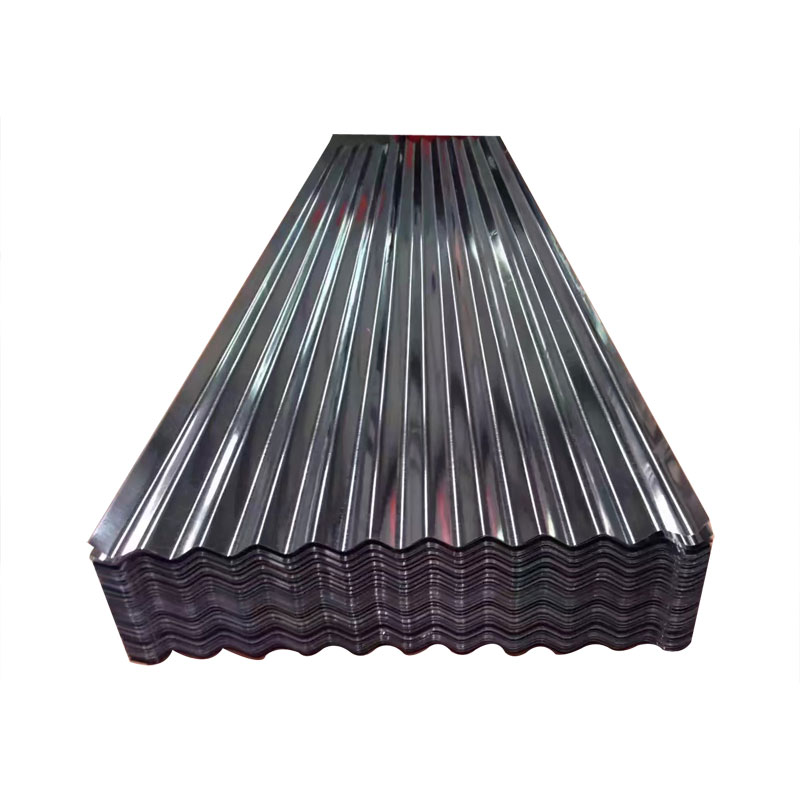

Metal Roofing Coil Materials

When you start looking for the best metal roofing coil, you’ll see a lot of choices. Each material has its own strengths, weaknesses, and price tag. Let’s break down what you need to know so you can pick the right one for your building.

Steel

Steel is the most popular choice for many projects. You’ll find it in homes, warehouses, and commercial buildings. Why do people like steel? It’s strong, affordable, and easy to work with.

Strength

Steel stands up to heavy loads and tough weather. If you want a roof that can handle snow, hail, or strong winds, steel is a solid bet. Galvanized and Galvalume-coated steel offer extra protection against rust. These coatings help your roof last longer, especially in places with lots of rain or humidity.

Durability

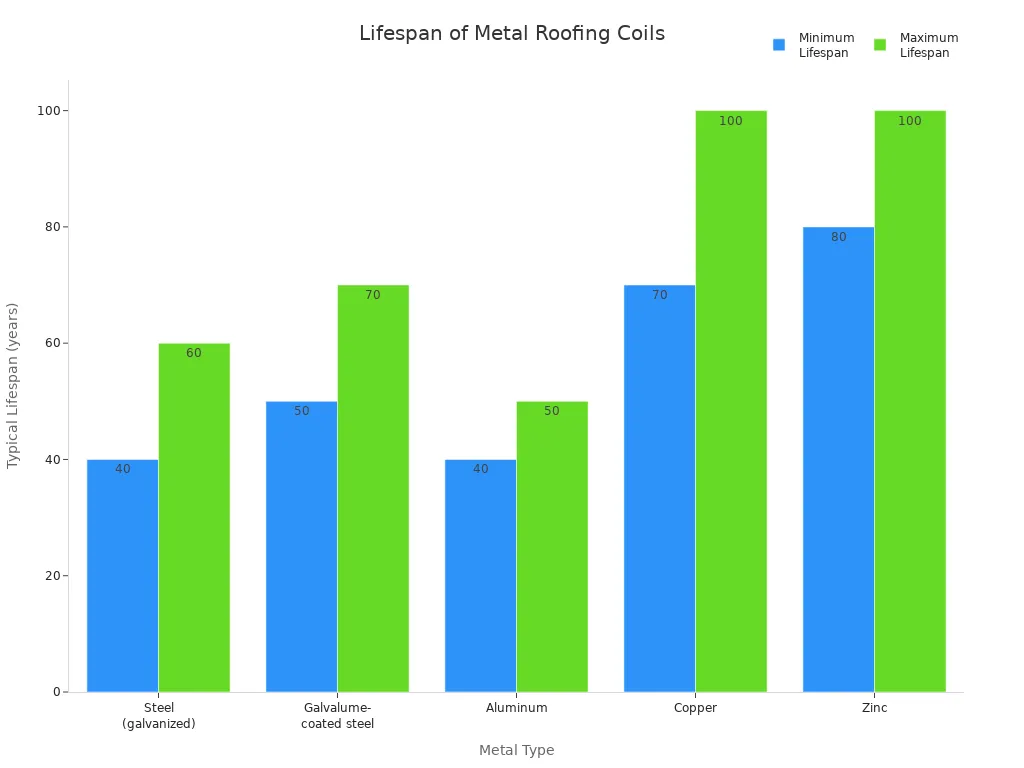

Steel roofs can last for decades. Galvanized steel usually gives you 40–60 years of service. Galvalume-coated steel can stretch that to 50–70 years. You get a cost-effective roof that doesn’t need much maintenance.

Here’s a quick look at how steel stacks up against other materials:

| Material | Cost Comparison | Performance Attributes |

|---|---|---|

| Aluminum | Generally cheaper than copper and zinc | Lightweight, strong, highly recyclable |

| Zinc | Expensive | Longevity, self-healing properties |

| Copper | High-cost option | Aesthetic appeal, historical use |

| Stainless Steel | High-end choice | Durable |

Aluminum

Aluminum is a favorite for buildings near water. If your project sits close to the ocean or a lake, you want a metal roofing coil that won’t rust.

Corrosion Resistance

Aluminum resists corrosion better than steel. Saltwater and humidity don’t bother it much. You’ll see aluminum roofs on coastal homes and marinas. They last 40–50 years and stay strong even when the weather gets rough. Aluminum is also lightweight, so it puts less stress on your building’s structure. Over time, the color may dull, but the metal keeps protecting your roof.

Tip: If you live by the coast, choose aluminum or zinc for your metal roofing coil. These metals fight off rust and keep your roof looking good longer.

Zinc & Copper

Zinc and copper are premium choices. You’ll pay more, but you get a roof that stands out and lasts for generations.

Longevity

Zinc and copper roofs can last 80–100 years. Zinc has a self-healing layer that repairs small scratches and keeps rust away. Copper develops a green patina over time, which protects the metal and gives your building a classic look. Both metals resist corrosion, even in harsh climates.

Here’s a table showing how these metals handle corrosion in coastal environments:

| Metal | Corrosion Resistance Properties | Strength Compared to Steel | Cost |

|---|---|---|---|

| Copper | Highly corrosion-resistant but can stain runoff areas. | Lower | High |

| Aluminum | Highly corrosion-resistant but dulls in color over time. | Lower | High |

| Zinc | Highly corrosion-resistant but darkens in color and has a high cost. | Lower | High |

| Stainless Steel | Strong but may corrode at fasteners made of carbon steel. | Strong | N/A |

| Galvanized Steel | Strong but has shorter resistance to salt corrosion. | Strong | N/A |

| Zinc-Alum Coated Steel | Strong with higher resistance to corrosion than galvanized steel. | Strong | N/A |

If you want a roof that will last a lifetime and look unique, zinc and copper are hard to beat. They cost more up front, but you save money on repairs and replacements.

Check out this chart to see how long each metal roofing coil can last:

Quick Comparison

- Steel: Strong, affordable, and durable. Good for most climates.

- Aluminum: Lightweight and resists rust. Best for coastal or humid areas.

- Zinc: Long-lasting and self-healing. Great for high-end projects.

- Copper: Beautiful and historic. Offers unmatched longevity.

When you choose a metal roofing coil, think about your location, your budget, and how long you want your roof to last. If your building sits near water, pick aluminum or zinc for the best corrosion resistance. If you want a roof that makes a statement and lasts for generations, copper or zinc might be the way to go.

Coil Specifications

Choosing the right coil specs is just as important as picking the right metal. If you get the details wrong, your roof might not fit, look right, or last as long as you want. Let’s break down what you need to know about thickness, width, color, and finish before you order your metal roofing coil.

Thickness

Gauge

When you hear people talk about “gauge,” they mean the thickness of the metal. The lower the gauge number, the thicker the metal. Thicker metal gives you more strength and better protection, but it also costs more and weighs more.

Here’s a quick table to help you see the most common gauges and their minimum thickness:

| Application Type | Gauge | Minimum Thickness (inches) |

|---|---|---|

| Residential (Standing Seam) | 26 | 0.0187 |

| Residential (Thru-Fastened) | 29 | 0.0142 |

| Commercial/Heavy-Duty | 24 | 0.023 |

| Standard Residential/Light Duty | 26 | 0.018 |

Most homes use 26 or 29 gauge. Commercial buildings often go thicker, like 24 gauge, for extra strength.

Structural Needs

You want your roof to handle whatever nature throws at it. Thicker gauges do a better job in tough weather. Here’s why:

- Thicker metal stands up to high winds, hail, and heavy snow.

- It resists dents, punctures, and warping over time.

- Thicker panels stay stable during installation and last longer.

- If you live in a hurricane zone, thicker metal and narrower panels help your roof stay put in winds up to 150 mph or more.

Keep in mind, thicker metal weighs more. Your building needs to support that extra weight. Always check with your contractor or engineer if you’re not sure.

Width

Profile Compatibility

Coil width matters for both looks and installation. You need to match the coil width to your roofing profile and the machine that shapes your panels. If you get this wrong, you could waste material or end up with panels that don’t fit.

Here’s a table showing standard coil widths and how they affect installation:

| Standard Widths (Effective Coverage) | Description | Impact on Installation Efficiency |

|---|---|---|

| 686mm | Most common size worldwide, especially in Africa/Middle East | Balances coverage and material use, speeds up installation |

| 762mm | Common in Australia, New Zealand, parts of Europe | Covers more area per sheet, so you need fewer sheets and finish faster |

Tip: Always check your rollforming machine’s specs before you order. Make sure the coil width matches what your machine can handle. If you use an overhead reel rack, know the maximum coil weight too. This helps you avoid jams, wasted metal, or costly delays.

Color & Finish

Paint Systems

The color and finish you choose do more than just make your building look good. They protect your roof from sun, rain, and rust. Not all paint systems are the same. Some last longer and resist fading better than others.

Here’s a quick comparison of the most common paint systems:

| Paint System | Fade Resistance | Longevity |

|---|---|---|

| Polyester | Low | Short-term |

| Silicone Modified Polyester (SMP) | Moderate | Mid-term |

| Fluoropolymer/PVDF (Kynar 500®) | High | Long-term |

- Polyester: Cheapest, but fades and chalks quickly.

- SMP: Better than polyester, but not the best for long-term color.

- PVDF (Kynar 500®): Top choice for fade resistance and long life. Keeps its color even in harsh sun.

If you want your roof to look sharp for decades, go with PVDF. It stands up to UV rays and keeps its color longer than other paints.

Fade Resistance

You can pick from over 40 colors for your metal roof. Some colors, like Midnight Bronze, give you a classic look and hold up well over time. High-performance finishes keep your roof looking new, even after years of sun and rain.

Galvanized finishes, like G-30, G-60, and G-90, add a layer of zinc to steel. This helps stop rust and keeps your roof strong in tough weather. The higher the number, the more zinc, and the better the protection.

Note: Always match your color and finish to your building’s style and the local climate. Some finishes work better in salty air or strong sun.

Matching Coil Specs to Your Roofing Machine

Before you place your order, double-check these steps:

- Know what your rollforming machine can handle—thickness, width, and coil weight.

- Give your supplier the exact coil dimensions you need.

- Make sure the coil matches your machine’s specs to avoid problems during installation.

If you get these details right, you’ll save time, money, and headaches. Your metal roofing coil will fit perfectly, look great, and last for years.

Supplier & Quality

Supplier Choice

Picking the right supplier for your metal roofing coil matters more than you might think. You want a roof that lasts, looks good, and stands up to tough weather. If you go with the cheapest supplier, you risk getting low-quality materials that can fail early. That means leaks, rust, and expensive repairs down the road. Reliable suppliers help you avoid these problems by following strict quality standards.

Quality Assurance

You should always check if your supplier meets recognized certifications and standards. These show that the company cares about quality and safety. Here’s a quick table to help you spot the most important ones:

| Certification/Standard | Description |

|---|---|

| ISO 9001 | General quality management system certification ensuring a well-defined quality management process. |

| ASTM Standards | Specific standards like ASTM A1011/A1011M that define chemical composition, mechanical properties, and dimensional tolerances for hot-rolled steel. |

| EN Standards | European Norms like EN 10025 that specify requirements for structural steels, including chemical composition and mechanical properties. |

| JIS Standards | Japanese Industrial Standards such as JIS G3101 that outline requirements for general structural rolled steel. |

When you choose a supplier with these certifications, you get coils that resist cracking, warping, and rusting. Your roof will last longer and need fewer repairs. You also get better color retention and protection against fading and chalking.

Warranty

A good warranty gives you peace of mind. Suppliers offer different types of warranties, like substrate, paint, and weathertight coverage. Some companies promise “lifetime” warranties, but you need to read the fine print. Coverage periods and exclusions can vary a lot. Look for warranties that cover paint system integrity, substrate protection, and performance metrics. For example, Galvalume® offers a warranty against perforation, while Galvanized does not. Always ask your supplier to explain what’s included and what’s not.

Tip: Don’t let a long warranty fool you. Sometimes, companies offer longer warranties for lower quality products. Make sure you understand what the warranty really covers.

Order Details

Once you pick a reliable supplier, you need to get your order details right. Clear communication helps you avoid mistakes and delays.

Quantity

Figure out exactly how much coil you need for your project. Order too little, and you’ll face delays. Order too much, and you waste money. Suppliers can help you estimate the right amount based on your roof size and design.

Lead Time

Lead time is how long it takes for your order to arrive. If you need your metal roofing coil fast, ask about turnaround times before you order. Here’s a table showing typical lead times from major North American suppliers:

| Supplier | Lead Time for Custom Orders | Notes |

|---|---|---|

| Pro Cut Metals | 1-2 days | Quick turnaround due to inventory in stock. |

| Hixwood | 4 hours to 1 week | Same day or next day for re-roofing. |

| Hixwood (Materials) | 1 week to 3 months | Varies by material type. |

If you plan ahead and communicate clearly, you’ll get your coils on time and keep your project moving.

Note: Reliable suppliers deliver on schedule and help you avoid costly delays. They also provide better warranties and support if something goes wrong.

Installation Compatibility

Equipment

Roll Forming

When you start installing metal roofing coils, you need the right equipment. If you use the wrong tools, your panels might not fit, and you could end up with leaks or extra repairs. You want your roof to look sharp and last for years, so let’s talk about what you need.

Here’s a table showing the most important tools for metal roofing coil installation:

| Equipment/Tool | Purpose/Use |

|---|---|

| Measuring tools | For accurate measurements during installation |

| Long straight-edge | To ensure straight cuts and alignments |

| Rivet gun | Used for securing ridgelines |

| Panel hemming tool | Trims panels to fit into cleats |

| Duckbill snips | For making long cuts on flat panels |

| Seaming tool | Attaches seams together |

| Turbo shear | For making fast cuts |

| Power supply | Needed for cutting and fastening tools |

You want to use tools that match your coil specs and roofing machine. If your equipment doesn’t fit the coil, you might see gaps, crooked seams, or panels that don’t lock together. That means more work and higher costs later. Always check your roll forming machine’s specs before you start. If you manage your power supply well, you avoid interruptions and keep your crew moving.

Tip: Compatible tools make installation faster and smoother. If you use the wrong equipment, you might need extra maintenance or repairs down the road.

Accessories

Fasteners

Fasteners hold your metal panels in place. You want fasteners that resist corrosion and keep your roof tight, even in bad weather. If you pick the wrong fasteners, water can sneak in and cause rust or leaks. Stainless steel or coated fasteners work best for most metal roofs. You should match the fastener type to your coil material for the best results.

Flashings

Flashings protect the edges and joints of your roof. You need them around valleys, ridges, and eaves. Flashings keep water out and help your roof last longer. If you skip flashings or use the wrong type, you might see leaks or damage after the first big storm.

Here’s a table with key accessories for metal roofing coil installations:

| Accessory | Purpose |

|---|---|

| Eave Trim | Directs water away from the building and improves appearance |

| Fasteners | Secure panels and keep your roof weather-tight |

| Underlayment | Adds a layer of protection against moisture |

| Sealants | Seals seams and laps to block water infiltration |

| Other Components | Includes rake trim, ridge caps, and valley flashings for complete protection |

Note: Don’t forget underlayment and sealants. These add extra protection and help your roof handle heavy rain or snow.

If you use the right equipment and accessories, your metal roofing coil will fit perfectly and stay strong for years. You’ll avoid leaks, rust, and costly repairs. Take your time, double-check your tools, and choose accessories that match your project. Your roof will thank you!

Common Mistakes

Overlooking Codes

You might think building codes are just paperwork, but they protect your investment. If you skip checking local codes, you risk installing a roof that doesn’t meet safety standards. Some areas require specific fire ratings or wind resistance. If your roof doesn’t match these rules, inspectors can force you to replace it. That means extra costs and wasted time. You also risk fines or delays if you ignore codes. Always ask your local building department about the latest requirements before you order your metal roofing coil. This step saves you headaches and keeps your project on track.

Wrong Material

Picking the wrong material for your metal roofing coil can turn into a costly mistake. You want your roof to last, but using the wrong metal in the wrong climate can cause big problems. For example, steel might rust quickly near the ocean, while aluminum works better in salty air. If you choose a coil that doesn’t fit your weather conditions, you could face:

- Premature wear and tear, which means your roof won’t last as long as you hoped.

- Voided warranties, so you pay out of pocket for repairs.

- Total roof failure during extreme weather, like hurricanes or heavy snow.

You don’t want to spend money fixing leaks or replacing panels every few years. Take time to match your coil material to your climate and building needs. Ask your supplier for advice if you’re unsure.

Incorrect Specs

Getting the specs wrong can mess up your whole project. If you order the wrong thickness, width, or finish, your panels might not fit or perform as expected. This mistake can also affect your warranty. Manufacturers set strict rules for coverage, and if you don’t follow them, you lose protection.

Here’s a table showing common warranty types for Galvalume substrates:

| Warranty Type | Description |

|---|---|

| AZ50 | Painted Galvalume substrate warranty |

| AZ55 | Unpainted (or acrylic-coated) Galvalume warranty |

Warranties often get voided for reasons like:

- Bends that are thinner than the required thickness.

- Roof slopes flatter than the minimum ratio.

- Poor drainage that lets water pool on the roof.

- Mechanical or chemical damage during installation.

- Improper handling or storage before installation.

- Damage from contact with corrosive materials.

If you don’t double-check your specs, you risk leaks, rust, and expensive repairs. Always confirm your coil thickness, width, and finish before you order. Talk to your supplier about warranty details and installation tips. This way, you protect your investment and avoid common pitfalls.

Poor Supplier Choice

You might think saving money by picking the cheapest supplier is a smart move. It sounds good at first, but this decision can cause big problems for your metal roofing project. When you choose a supplier who cuts corners, you risk getting coils that just don’t measure up.

Let’s break down what can go wrong if you go with a low-cost or unverified supplier:

| Risk Type | Description |

|---|---|

| Low-Quality Products | Products may not meet durability standards, leading to premature failure. |

| Lack of Warranties | Unverified suppliers often do not provide warranties, increasing risk for buyers. |

| Poor Paint System | Cheap paint systems can lead to color fading and reduced longevity. |

| Inadequate Metal Substrate | Low-cost metal may not meet necessary standards, affecting overall product performance. |

| Shipping and Packaging Issues | Consistent damage during shipping can compromise product integrity. |

| Incorrect Specifications | Products may not match advertised qualities, leading to customer dissatisfaction. |

You want your roof to last for decades, not just a few years. If you get coils with poor paint systems, you’ll see fading and chalking way too soon. Your building might look worn out before you know it. Some suppliers use metal that doesn’t meet industry standards. This means your roof could bend, warp, or even leak after the first storm.

Have you ever heard of a supplier who doesn’t offer a warranty? That’s a huge red flag. If something goes wrong, you’re stuck with the bill. Reliable suppliers stand behind their products. They give you clear warranties and help you if problems pop up.

Shipping and packaging matter too. If your coils arrive damaged, you lose time and money. You might need to reorder or fix panels before you even start. Good suppliers pack their products carefully and ship on time.

Tip: Always ask your supplier about their quality checks, certifications, and warranty details. If they dodge your questions or give vague answers, look somewhere else.

Here’s what you can do to avoid supplier mistakes:

- Check reviews and ratings online. Other customers can tell you a lot.

- Ask for proof of certifications like ISO 9001 or ASTM standards.

- Request samples before you place a big order.

- Make sure the supplier offers a clear warranty and explains what it covers.

- Confirm they can deliver the exact specs you need for your project.

Choosing the right supplier isn’t just about price. It’s about trust, quality, and peace of mind. When you work with a reliable company, you get coils that fit, last, and look great. You avoid headaches, costly repairs, and unhappy surprises. Take your time, ask questions, and pick a supplier who cares about your project as much as you do. Your roof—and your wallet—will thank you!

Metal Roofing Coil Checklist

Steps

Ready to order your metal roofing coil? Let’s walk through the steps so you don’t miss anything important. You want your roof to look great and last for years, so double-check each part of the process.

1. Pick your material, color, and thickness. Decide what works best for your climate and building style. 2. Write down the exact coil dimensions and how many coils you need. 3. Check your rollforming machine’s specs. Make sure it can handle the coil size and thickness. 4. Figure out the number of sheets you’ll need for full coverage. 5. Match all accessories, like fasteners and flashings, to your roof profile. 6. Ask your supplier about lead times. You want your coils to arrive when you need them. 7. Include your company info on the order. This helps with tracking and warranty claims.

Tip: If you follow these steps, you’ll avoid common mistakes like ordering the wrong size or forgetting key accessories.

Review Specs

Before you hit “confirm,” take a few minutes to review your specs. This step saves you from headaches later. Here’s a table to help you check the most important details:

| Specification Criteria | Details |

|---|---|

| Manufacturer vs. Supplier | Decide if you want to work directly with a factory or a trading company. |

| Production Capability & Scale | Check the factory’s size and yearly output. |

| Operational Reliability | Look for fast response times and on-time delivery rates. |

| Quality Control | Ask about testing equipment and internal QC processes. |

| Experience & Longevity | Choose companies with a strong track record. |

| Industry Standards | Make sure they follow national and international standards. |

| Quality Verification Methods | Request Mill Test Certificates and consider factory audits. |

| Sample Testing | Test samples for coating thickness and strength. |

| Customer Reviews & References | Read reviews and ask for references from other clients. |

You should also confirm your color choice and decide if you want painted or unpainted coils. Check the coil size and make sure your machine can handle it. Identify the panel widths you need for your project. Ask your supplier if their materials meet your quality standards.

Note: A quick review now can save you time and money later. If you spot a mistake, you can fix it before your order ships.

Confirm Order

Once you’ve checked everything, it’s time to confirm your order. Make sure you include all the details so your supplier knows exactly what you want. Here’s a table showing what to include:

| Information Type | Description |

|---|---|

| Order Specifications | List coil dimensions, colors, and quantities. |

| Tracking and Management Practices | Use inventory systems to track your order and manage stock. |

| Shipping and Delivery Tracking | Schedule shipping dates and confirm delivery with signatures or photos. |

| Reporting and Reconciliation | Track which coils you use for warranty and inventory management. |

You can ask for a dedicated account manager to help with your order. If you have questions about shipping or timing, reach out for support. Good suppliers help you track your order and solve problems fast.

Callout: Double-check your order before you send it. If you include all the right info, you’ll get your coils on time and avoid delays.

You want your metal roof to last and look great. Start by focusing on the basics:

| Factor | Description |

|---|---|

| Roof Specifics | Think about roof shape, slope, panel length, and your building’s structure. |

| Aesthetics | Pick colors and designs that boost your building’s style. |

| Substrates & Coatings | Choose materials and coatings that offer strong durability and performance. |

A quick chat with a professional supplier can make a big difference. Their advice helps you match the right coil to your project’s needs and avoid costly mistakes.

FAQ

What is the best metal for a roof near the ocean?

Aluminum works best for coastal areas. It resists rust and stands up to salty air. You get a roof that lasts longer and needs less maintenance.

How do I know which coil thickness to choose?

Check your local weather and building codes. Thicker coils handle heavy snow and strong winds. Your contractor can help you pick the right gauge for your project.

Can I install metal roofing coils myself?

You can try, but it’s tricky. You need special tools and experience. If you want a roof that looks good and lasts, hire a professional installer.

Do metal roofing coils come in different colors?

Yes! You can choose from many colors and finishes. Some paint systems last longer and resist fading. Ask your supplier for color samples before you order.

How long does a metal roof last?

Most metal roofs last 40 to 70 years. Zinc and copper can last over 100 years. Regular cleaning and inspections help your roof stay strong.

What should I look for in a supplier?

Pick a supplier with good reviews, clear warranties, and quality certifications. Reliable suppliers deliver on time and help you avoid costly mistakes.

Will my metal roof need special fasteners?

Yes. You need fasteners that match your coil material. Stainless steel or coated fasteners work best. They help prevent leaks and rust.

Can I use metal roofing coils on any building?

You can use metal roofing coils on homes, barns, warehouses, and more. Just make sure your building’s structure can support the weight and your roof design fits the coil specs.