Fluorocarbon color coated plate is a widely used multiple fields with many advantages.

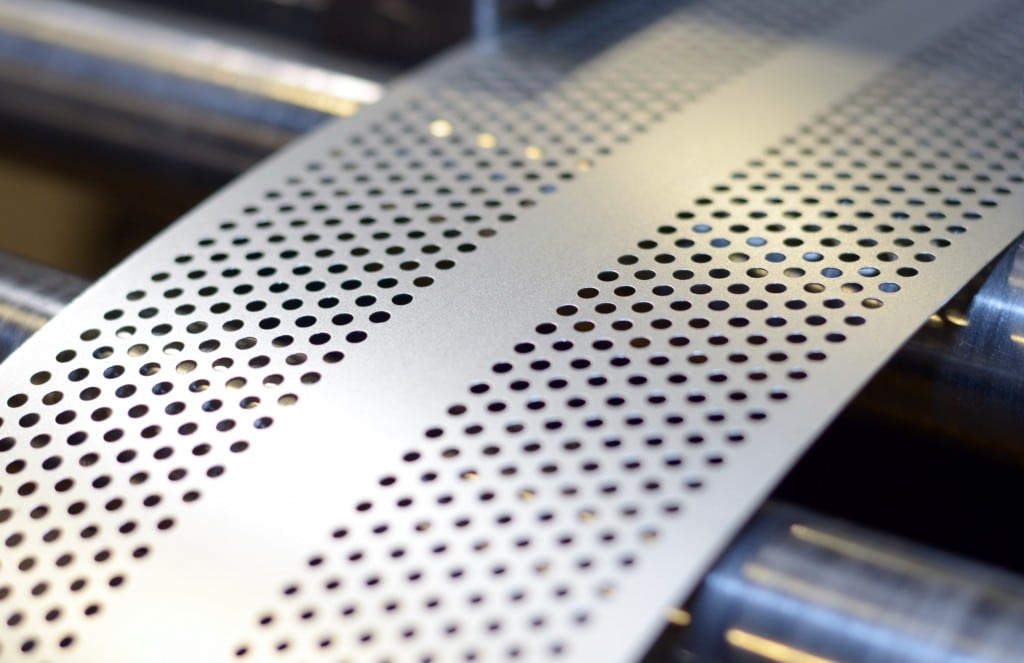

Firstly, fluorocarbon color coated sheet is a surface treatment material made of fluorocarbon resin as the substrate and baked at high temperatures. It has characteristics such as high strength, good weather resistance, and strong corrosion resistance. At the same time, fluorocarbon coated panels also have a certain self-cleaning function, which can reduce the frequency of cleaning and maintenance to a certain extent.

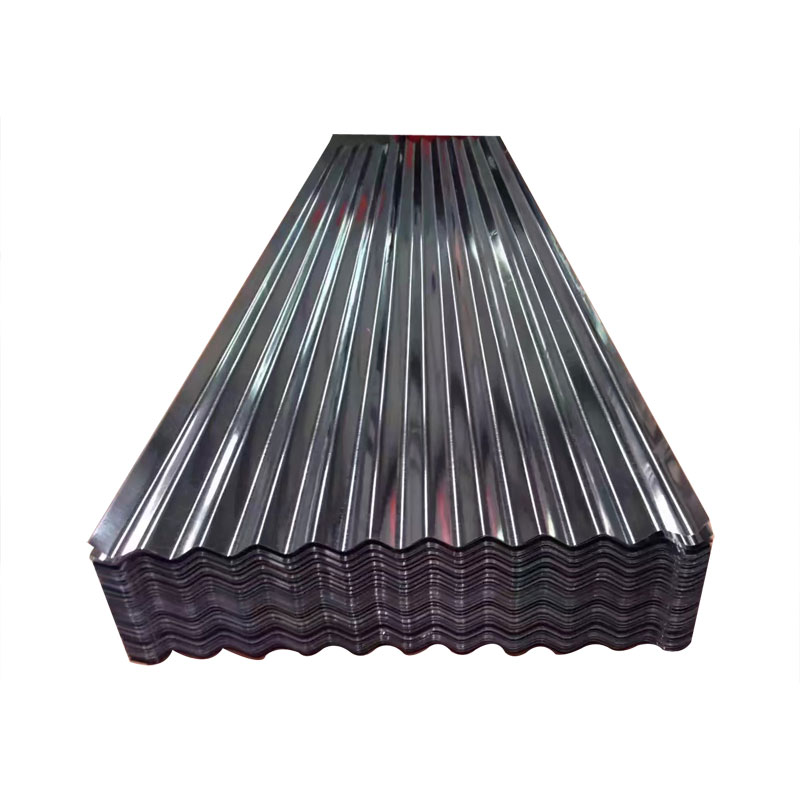

Fluorocarbon color coated panels have a wide range of applications in the construction industry. Firstly, it is often used for exterior wall decoration. Due to its excellent weather resistance and weathering resistance, fluorocarbon coated panels can maintain bright colors and beautiful appearance for a long time, and are not easy to fade and deform. This makes it the first material for exterior wall decoration of high-end residential and commercial buildings. At the same time, fluorocarbon color coated panels can effectively resist the erosion of external environments such as acid rain and ultraviolet radiation, extending the service life of buildings.

Secondly, fluorocarbon color coated panels are also widely used in indoor decoration. Its flat surface and diverse color choices make it an ideal choice for decorative materials such as indoor walls and ceilings. The installation of fluorocarbon color coated panels is simple and the construction cycle is short, which can meet the requirements of fast-paced engineering progress. At the same time, it also has certain sound insulation and heat insulation performance, which can improve the indoor environment and improve the comfort of living and working.

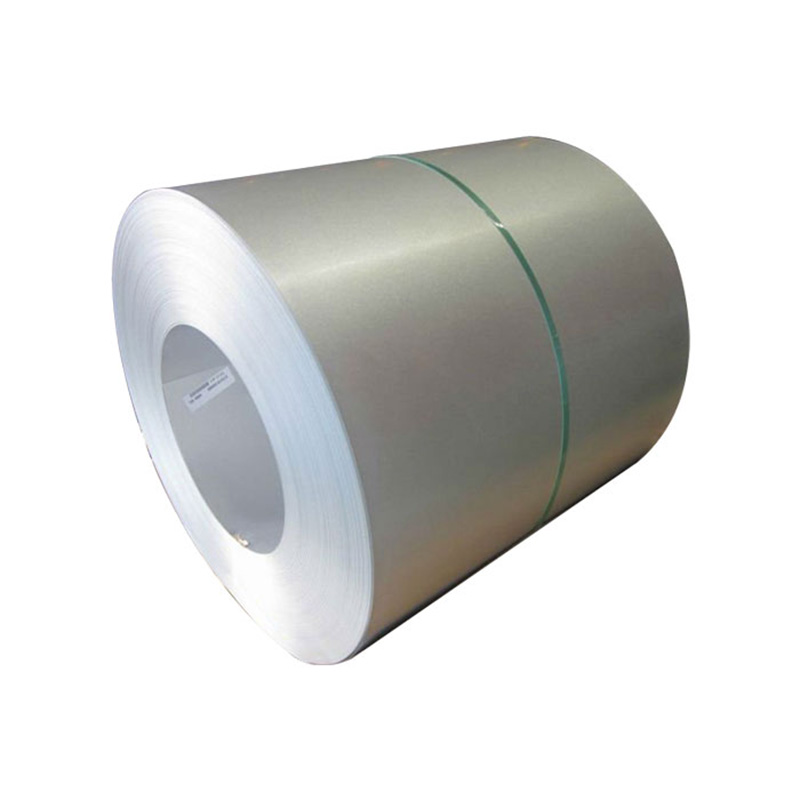

In addition to the construction industry, fluorocarbon color coated panels are also widely used for the exterior decoration of transportation vehicles. It has good weather resistance and high color stability, and can maintain good appearance effects in harsh external environments. Therefore, many vehicles such as cars, trains, and ships are decorated with fluorocarbon color coated panels on the exterior, improving the overall aesthetics and quality.

Overall, the advantages and application fields of fluorocarbon color coated panels are very extensive. It can not only provide good appearance and protective performance for buildings, but also meet the needs of different fields. With the progress of technology and people’s attention to environmental protection, fluorocarbon color coated panels will continue to play an important role in the future.