WHAT IS GALVALUME METAL ROOF?

A Galvalume metal roof is a roofing system made from Galvalume-coated steel, which is designed to provide superior durability, corrosion resistance, and longevity.

Galvalume VS Aluzinc VS Zincalume

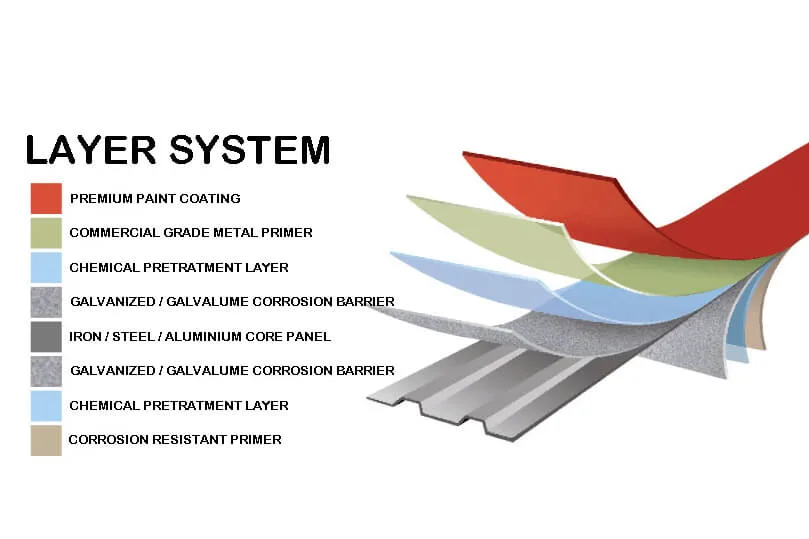

ZINCALUME, also known by the trade name Galvalume and Aluzinc, is a specialized coating applied to steel before it is painted. This metallic coating consists of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon. The combination of these metals creates a protective barrier that significantly enhances the steel’s resistance to rust and corrosion, even in harsh environments. The aluminum component offers excellent resistance to atmospheric corrosion, while the zinc component sacrificially corrodes to protect the underlying steel.

The Advantages of Galvalume metal roof?

Galvalume is a steel product coated with a mixture of aluminum, zinc, and silicon, providing superior corrosion resistance. Invented by Bethlehem Steel in the 70s, Galvalume offers numerous benefits for both residential and commercial buildings:

- Superior Corrosion Resistance: The 55% aluminum, 43.5% zinc, and 1.5% silicon coating offers excellent protection against rust, even in harsh environments.If you’re looking for a long-lasting roof with multiple benefits, such as resistance to corrosion and pest infestation, Galvalume is an excellent choice. These roofs can last between 40 to 60 years, depending on the local weather conditions in your area.

- Energy Efficiency: The reflective aluminum reduces heat absorption, lowering cooling costs.Galvalume excels at combating rust and corrosion. Thanks to its coating of zinc, silicon, and aluminum, a Galvalume metal roof provides superior resistance to rust and other forms of corrosion. It’s like having a waterproof and bug-repellent shield, making it especially ideal for cold and icy regions where snow and water damage are common issues. Here’s another reason why homeowners love Galvalume roofs: they’re low maintenance.

- Low Maintenance: The zinc coating I mentioned earlier offers excellent self-healing and protection properties. Unlike other roofing materials that often require regular treatments or sealants, Galvalume panels need minimal upkeep. This means you won’t have to spend much time or money on maintenance. Convenient, right?

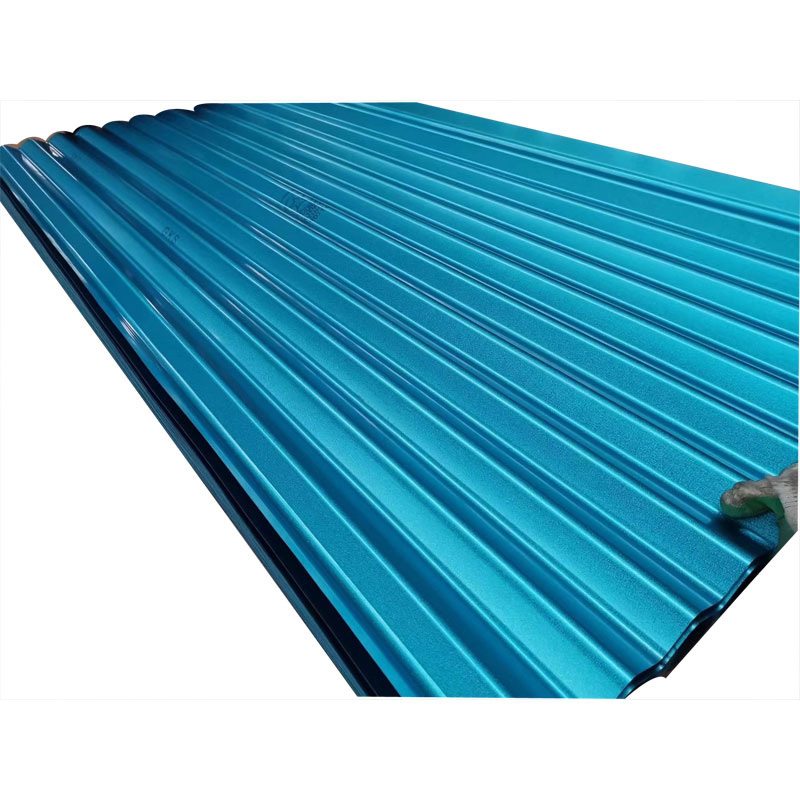

- Aesthetic Appeal: Galvalume steel panels can be customized to match your home’s specifications and architecture. Flexibility is the name of the game here. You can even create unique roof shapes and configurations by working with your metal roofing contractor.

- Environmental Friendliness: Galvalume metal roofs are 100% recyclable, and that includes its coating. So, you’re not merely securing your home, but also doing your part for the environment. The long lifespan of a Galvalume roof also means fewer replacements, which reduces waste.

- Fire Resistance: Galvalume roofs are non-combustible, and the additional layers of coating provide enhanced protection for your home. If you reside in an area susceptible to thunderstorms or wildfires, a Galvalume roof can offer peace of mind.

- Lightweight: Despite their strength and durability, Galvalume metal panels are relatively lightweight, reducing the structural load on buildings and simplifying installation.

- Cost-Effectiveness: Galvalume metal roofs might come with a slightly higher initial cost compared to certain other materials, but they represent a sound long-term investment. Why? Their remarkable durability eliminates the need for frequent repairs or replacements, ultimately saving you money over time. Additionally, Galvalume steel is energy-efficient, abundant, and readily accessible.

You may be curious about the potential drawbacks of this highly advantageous roofing material. Let’s delve into some considerations or disadvantages associated with Galvalume roofs. The disadvantages of a Galvalume metal roof include:

- Higher initial cost: Compared to some other roofing materials, Galvalume metal roofs may have a higher initial cost.

- Potential for scratches and wear: While Galvalume is corrosion-resistant, it may develop scratches and wear over long-term use.

- Requires professional installation: Installing a Galvalume metal roof requires professional skills and experience to ensure proper performance and longevity.

- Not suitable for all architectural styles: Due to its metallic appearance, a Galvalume metal roof may not be suitable for all architectural styles.

Please note that these disadvantages may not apply in all cases, and specific circumstances may vary depending on factors such as environment, installation quality, and maintenance.

GALVALUME VS. PAINTED METAL ROOF

In comparisons, Galvalume clearly surpasses other options. Its corrosion resistance far exceeds that of painted metal roofs. While a painted metal roof relies solely on the resins and pigments in the paint for protection, which can wear off over time, leaving the metal roof susceptible to corrosion, Galvalume offers a superior solution. It provides a roof that’s built to last, boasting greater durability and a longer lifespan than painted metal roofs.

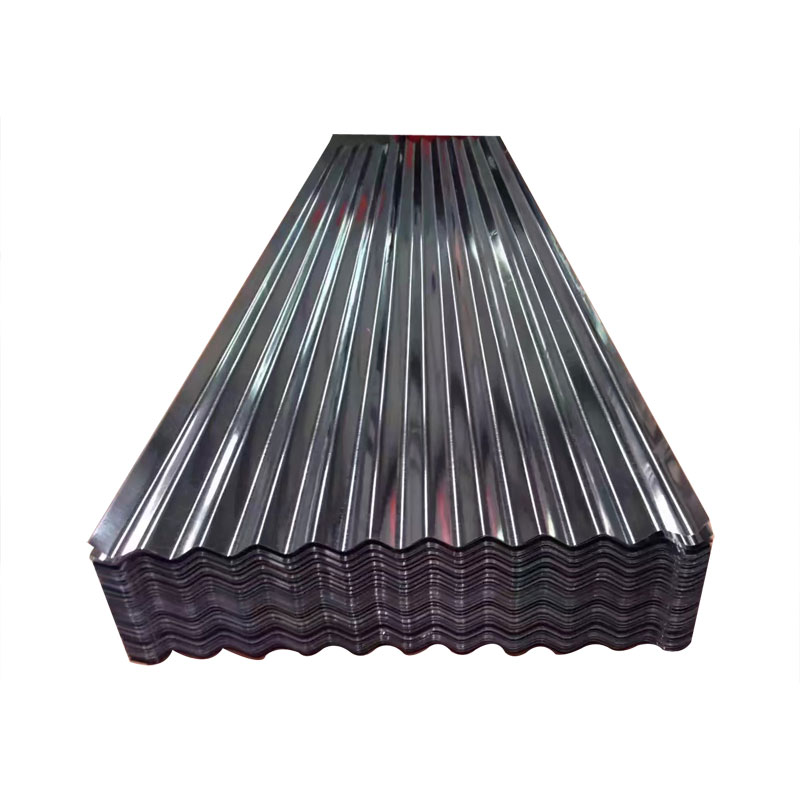

GALVALUME VS. GALVANIZED METAL

Galvanized panels are made by coating steel with a layer of zinc, which provides some protection against corrosion, but not as much as Galvalume. Since Galvalume panels are made from a combination of zinc, aluminum, and silicon, they offer superior weatherproofing and durability, which is better for most climates, including coastal areas. Both materials have similar price points, so the choice falls more on the type of durability you need.

How Much Does Metal Roofing Cost?

Galvalume steel is priced similarly to galvanized steel. Galvalume Metal roof is generally more affordable than other traditional standing seam metal roofing methods and lasts much longer.

Does the color fade in sunlight?

Painted roofs fade faster, but Galvalume maintains its color. That’s why Maverick Steel sells more coated metal – people know painted roofs will need repainting sooner, costing more in the long run. For preserving color and preventing fading, Galvalume is the best choice for architectural roofs. With proper maintenance, a galvanized steel roof can last for decades, saving time and money.

How to Find GALVALUME METAL ROOF and Galvalume Steel Suppliers?

If you want to find a reliable Galuvalume steel or metal roof factory in China, we will be happy to help you with a free consultation. I wrote an article about 5 Tips to Help You Select Galvanized Steel Coil Manufacturers in China. You can refer to this method to find good suppliers.