You need to understand the main classification methods for color-coated sheets to choose the right product for your project. These classifications include base material, coating type, gloss, surface treatment, post-processing, structural design, fire rating, and durability.

Knowing the differences helps you select coated sheets that offer protection against corrosion, reduce costs, support sustainability, and provide durability and convenience. This understanding ensures you get materials that fit your needs and last in demanding environments.

Key Takeaways

- Understand the main classification methods for color-coated sheets to choose the right product for your project.

- Color-coated galvanized steel coils (PPGI) offer excellent corrosion resistance and are suitable for both indoor and outdoor use.

- Color-coated Galvalume steel coils (PPGL) provide enhanced heat and corrosion resistance, making them ideal for harsh environments.

- Color-coated aluminum coils (PPAL) are lightweight and flexible, perfect for decorative applications and high-end architectural projects.

- Select the appropriate coating type based on your project’s needs, such as PE for general construction and PVDF for demanding environments.

- Consider gloss levels when choosing coated sheets; matte finishes offer a subtle look, while high gloss provides a bold, eye-catching finish.

- Surface treatments like sand and wrinkle can enhance aesthetics and durability, helping to hide scratches and fingerprints.

- Always check fire ratings and durability specifications to ensure safety and longevity in your selected coated sheets.

Color-Coated Sheets: Base Materials

Color-Coated Galvanized Steel Coil (PPGI)

Features

You will find that color-coated galvanized steel coils combine a zinc-coated steel base with a layer of organic paint. This combination gives you excellent corrosion resistance and a wide range of color options. You can use these coated sheets for both indoor and outdoor projects. The zinc layer protects the steel from rust, while the paint adds extra resistance to weather and chemicals.

Specifications

- Thickness range: 0.2mm to 1.2mm

- Width range: 600mm to 1250mm

- Standard grades: DX51D, DX52D

- International standards: These color coated sheet products meet strict quality requirements.

- Surface finish: Smooth, matte, or glossy

- Available as pre-coated steel sheets

Durability

You can rely on PPGI for long-term performance. The zinc coating and paint layer work together to provide high resistance to corrosion and scratches. These coated sheets pass multiple safety tests and meet international standards, which ensures you get consistent durability.

Applications

You can use color-coated galvanized steel coils in many application areas:

- Roofing and wall panels

- Home appliances

- Garage doors

- Fencing

- Construction and industrial buildings

Color-coated Galvalume steel coil (PPGL)

Features

PPGL uses a steel base coated with an alloy of aluminum and zinc. This gives you enhanced resistance to heat and corrosion. The aluminum-zinc layer provides better protection in harsh environments. You will notice that PPGL coated sheets offer high flexibility and impact resistance, making them suitable for demanding projects.

Specifications

- Thickness range: 0.2mm to 1.2mm

- Width range: 600mm to 1250mm

- Alloy composition: 55% aluminum, 43.5% zinc, 1.5% silicon

- Surface finish: Smooth, granular, or wrinkle

- Meets international standards for quality and safety

Durability

PPGL coated sheets deliver outstanding durability. The aluminum-zinc alloy resists oxidation and maintains its appearance over time. You can expect these color coated sheet products to perform well in coastal and industrial application areas.

Applications

You can use color-coated Galvalume steel coils in the following application areas:

- Coastal buildings

- Chemical plants

- Agricultural structures

- Solar panel frames

- Exterior wall cladding

Color-coated Aluminum coil (PPAL)

Features

Color-coated aluminum coils use an aluminum base with a layer of organic paint. You get lightweight coated sheets with excellent resistance to corrosion and weathering. Aluminum offers high flexibility and impact resistance, which makes these color coated sheet products easy to shape and install.

Specifications

- Thickness range: 0.2mm to 1.5mm

- Width range: 600mm to 1600mm

- Alloy grades: 3003, 3105, 5052

- Surface finish: Matte, glossy, or brushed

- Available as organic-coated sheets

Durability

You can trust PPAL for superior durability. Aluminum resists rust and chemical damage. The paint layer adds extra resistance to UV rays and moisture. These coated sheets maintain their color and strength in various climates.

Applications

You can use color-coated aluminum coils in many application areas:

- Decorative panels

- Ceiling tiles

- Signboards

- Transportation vehicles

- High-end architectural projects

Compare PPGI, PPGL, PPAL

| Type | Base Material | Resistance to Corrosion | Weight | Application Areas | Color Options |

|---|---|---|---|---|---|

| PPGI | Galvanized Steel | High | Medium | Construction, appliances | Wide |

| PPGL | Galvalume Steel | Very High | Medium | Coastal, industrial | Wide |

| PPAL | Aluminum | Excellent | Light | Decoration, transport | Wide |

Tip: You should choose PPGI for general construction, PPGL for harsh environments, and PPAL for projects that need lightweight and flexible coated sheets. All three types offer strong resistance and a variety of color options to match your needs.

Color Coated Sheet: Coating Types

PE

Features

You will find that PE polyester color coated sheet uses a polyester resin as its main ingredient. This resin gives coated sheets a smooth finish and vibrant color. You can choose from a wide range of colors to match your project. The paint layer adheres well to the metal surface, which helps prevent peeling and fading. You get a cost-effective solution for many applications.

Durability

PE polyester color coated sheet offers good durability for indoor and outdoor use. The paint layer resists UV rays and moisture. You can rely on these coated sheets for stable performance in moderate climates. The surface maintains its color and gloss over time.

Applications

You can use PE polyester color coated sheet in many areas. Construction projects often use these coated sheets for roofing and wall panels. You will see them in warehouses, commercial buildings, and residential homes. The table below shows which industry sectors use each coating type:

| Coating Type | Industry Sector |

|---|---|

| Polyester | Construction |

| SMP | Domestic Appliances |

| HDP | Furniture |

| PVDF | Transportation |

SMP

Features

SMP silicon modified color coated sheets use a silicon-modified polyester resin. This resin improves the flexibility and weather resistance of coated sheets. You get a surface that resists chalking and fading. The paint layer provides a glossy or matte finish, depending on your needs.

Durability

You can expect SMP silicon modified color coated sheets to last longer than standard polyester coatings. The silicon modification increases resistance to UV rays and chemicals. These coated sheets keep their color and gloss in outdoor environments.

Applications

You will find SMP silicon modified color coated sheets in domestic appliances. Manufacturers use these coated sheets for refrigerator panels, washing machine covers, and other household products. The improved durability makes them suitable for products that face frequent use.

HDP

Features

HDP high durability polyester color coated sheet uses a special polyester resin. This resin gives coated sheets enhanced resistance to weather and chemicals. You get a surface that stays bright and clean even in tough conditions. The paint layer offers a wide range of colors and gloss levels.

Durability

You can rely on HDP high durability polyester color coated sheet for excellent durability. The coating resists fading, chalking, and corrosion. These coated sheets perform well in outdoor furniture and architectural projects.

Applications

You will see HDP high durability polyester color coated sheet used in furniture and decorative panels. Designers choose these coated sheets for their long-lasting color and smooth finish. The high weather resistant color coated sheet is ideal for outdoor installations.

PVDF

Features

You will notice that PVDF color-coated sheets use polyvinylidene fluoride resin as the main coating. This resin gives you a surface with outstanding chemical resistance. You can expect these coated sheets to keep their color and gloss for many years. The PVDF coating forms a strong bond with the metal base. You get a finish that resists chalking, fading, and pollution. PVDF color-coated sheets also provide excellent flexibility. You can bend and shape these coated sheets without cracking the surface. The coating stands up to harsh weather, acid rain, and industrial fumes.

Durability

You can trust PVDF color-coated sheets for the highest level of durability among all coated sheets. The PVDF resin protects the metal from UV rays, salt spray, and chemicals. You will see that these coated sheets maintain their appearance even in extreme climates. The coating does not peel or blister. You get long-lasting protection for your projects. PVDF color-coated sheets pass strict durability tests and meet international standards.

Applications

You can use PVDF color-coated sheets in projects that demand the best performance. Architects choose these coated sheets for high-rise buildings, airports, and stadiums. You will find them in curtain walls, exterior panels, and roofing systems. PVDF color-coated sheets also work well in coastal areas and industrial zones. The coating resists corrosion from salt and chemicals. You can rely on these coated sheets for projects that require both beauty and strength.

Compare PE SMP HDP PVDF

When you compare the four main coating types for color-coated sheets, you will see clear differences in performance and application.

| Coating Type | Weather Resistance | Color Retention | Flexibility | Typical Applications |

|---|---|---|---|---|

| PE | Good | Good | High | Roofing, wall panels |

| SMP | Better | Better | High | Appliances, outdoor panels |

| HDP | Excellent | Excellent | High | Furniture, decorative panels |

| PVDF | Superior | Outstanding | High | High-end architecture, coastal projects |

You should choose PE color-coated sheets for general construction. SMP coated sheets give you better weather resistance for appliances and outdoor use. HDP coated sheets offer excellent durability for furniture and decorative panels. PVDF color-coated sheets provide the best protection and color stability for demanding environments. Each type of coated sheets serves a unique purpose. You can match the coating to your project needs for the best results.

Gloss Levels in Color-Coated Sheets

When you choose color-coated sheets, you need to consider the gloss level. Gloss affects both the appearance and the function of coated sheets. You can select from several gloss levels, including no gloss, matte, and semi-gloss. Each level offers unique features and works best in different applications.

No Gloss

Features

No gloss color-coated sheets have a completely flat finish. You will notice that these coated sheets do not reflect light. The surface absorbs light, which gives you a soft and subtle look. This finish hides fingerprints and small scratches well. You can expect a smooth and uniform appearance. No gloss coated sheets often use special paint formulas to achieve this effect.

Applications

You can use no gloss coated sheets in places where you want a calm and understated look. Many architects choose these coated sheets for modern buildings. You will see them in office interiors, ceilings, and wall panels. No gloss color-coated sheets also work well in public spaces where you want to reduce glare. Museums and galleries often use this finish to keep the focus on displays.

Matte

Features

Matte color-coated sheets offer a low-gloss finish. You get a surface that reflects very little light but still looks smooth. Matte coated sheets provide a soft texture and help hide minor surface flaws. The finish feels modern and elegant. You can find matte color-coated sheets in many colors and patterns.

Applications

You can use matte coated sheets in both residential and commercial projects. Homeowners often choose matte finishes for kitchen appliances and cabinets. Builders use these coated sheets for exterior wall cladding and roofing. Matte color-coated sheets help create a stylish and contemporary look. They also reduce eye strain in bright environments.

Semi-Gloss

Features

Semi-gloss color-coated sheets have a balanced shine. You will see a gentle reflection of light on the surface. This finish gives coated sheets a clean and polished look. Semi-gloss coated sheets are easy to clean and maintain. The surface resists stains and dirt. You can expect a durable finish that stands up to daily use.

International standards help you measure gloss in coated sheets. The table below shows common measurement angles and brightness levels:

| Measurement Angle | Brightness Level (ub) |

|---|---|

| 60º | 40 ± 5 |

| Minimum | 80 |

Applications

You can use semi-gloss coated sheets in schools, hospitals, and offices. These coated sheets work well for doors, partitions, and furniture. Semi-gloss color-coated sheets give you a professional and welcoming atmosphere. You can also use them in areas that need frequent cleaning.

High Gloss

Features

High gloss color-coated sheets give you a bright, mirror-like finish. You will notice that these coated sheets reflect a lot of light. The surface looks smooth and shiny. This finish makes colors appear more vivid and bold. You can easily spot high gloss coated sheets because they stand out in any environment.

The paint layer on these coated sheets uses special resins that create a hard, glossy surface. This layer helps protect the coated sheets from scratches and stains. You will find that high gloss color-coated sheets are easy to clean. Dust and dirt do not stick to the surface for long. You can wipe them with a soft cloth to keep them looking new. The gloss level also helps resist fading from sunlight. High gloss coated sheets keep their shine for many years.

Applications

You can use high gloss color-coated sheets in places where you want to make a strong visual impact. Many designers choose these coated sheets for modern buildings and commercial spaces. You will see high gloss coated sheets in shopping malls, showrooms, and office lobbies. These coated sheets work well for decorative panels and signage. You can also use them in kitchens and bathrooms because the smooth surface resists moisture and stains. High gloss coated sheets are popular in the automotive industry. Car manufacturers use these coated sheets for vehicle interiors and trim. You can find them in furniture, cabinets, and appliances. The shiny finish adds a touch of luxury to any space.

Compare Difference Gloss Type

You have many options when you select the gloss level for color-coated sheets. Each gloss level gives you a different look and feel. Here is a simple table to help you compare the four main types:

| Gloss Level | Light Reflection | Appearance | Cleaning Ease | Typical Uses |

|---|---|---|---|---|

| No Gloss | None | Soft, subtle | Easy | Museums, galleries, ceilings |

| Matte | Low | Modern, elegant | Easy | Homes, offices, exteriors |

| Semi-Gloss | Medium | Clean, polished | Very Easy | Schools, hospitals, furniture |

| High Gloss | High | Bright, bold | Very Easy | Showrooms, kitchens, signage |

Tip: You should choose no gloss or matte color-coated sheets for a calm and understated look. Semi-gloss coated sheets work well in busy areas that need frequent cleaning. High gloss color-coated sheets give you a bold, eye-catching finish. You can match the gloss level of coated sheets to your design goals and the needs of your project. Each type of color-coated sheets offers unique benefits for different spaces.

Surface Treatments for Color-Coated Sheets

Sand

Features

You can choose sand surface treatments for color-coated sheets when you want a subtle, textured finish. This treatment creates a fine, grainy look that feels slightly rough to the touch. Sand finishes help reduce glare and add depth to the appearance of coated sheets. You will notice that sand surfaces hide fingerprints and minor scratches well. Manufacturers often use polyester coatings for sand finishes. These coatings enhance the aesthetic appeal and provide good resistance to weathering. The sand texture also improves grip, making the coated sheets easier to handle during installation.

Applications

You will find sand surface color-coated sheets in modern architecture and interior design. Architects use them for wall panels, ceilings, and decorative facades. Sand finishes work well in public spaces where you want to minimize reflections. You can also use these coated sheets in commercial buildings, schools, and offices. The sand texture adds a sophisticated touch to any environment.

Granular

Features

Granular surface treatments give color-coated sheets a distinctive, pebble-like texture. You will see small, raised particles on the surface, which create a unique visual effect. Granular finishes increase the durability of coated sheets by making them more resistant to scratches and dents. Epoxy primer coatings often serve as the base for granular finishes. These coatings offer superior adhesion and corrosion resistance, which contributes to the long-term performance of the coated sheets. The granular texture also helps reduce slipping, making these sheets suitable for flooring and exterior applications.

Applications

You can use granular color-coated sheets in areas that require extra durability and safety. Builders often select them for industrial floors, staircases, and walkways. The textured surface provides better traction, which helps prevent accidents. You will also find granular finishes in outdoor installations, such as playground equipment and sports facilities. The unique look of granular coated sheets makes them popular for decorative accents in commercial spaces.

Scratch Resistant

Features

Scratch resistant surface treatments protect color-coated sheets from everyday wear and tear. You get a tough, durable finish that stands up to frequent contact and movement. Manufacturers use advanced coating technologies to create a hard layer on the surface. This layer prevents scratches, scuffs, and marks, keeping the coated sheets looking new for longer. Scratch resistant finishes often combine polyester and epoxy primer coatings. These coatings work together to provide excellent resistance to weathering and corrosion. You will appreciate the easy maintenance and long-lasting beauty of scratch resistant coated sheets.

Applications

You can rely on scratch resistant color-coated sheets in high-traffic areas. Many people use them for doors, partitions, and furniture in schools, hospitals, and offices. The tough surface makes these coated sheets ideal for public spaces and commercial buildings. You will also find scratch resistant finishes in transportation vehicles and home appliances. The protective layer ensures that the coated sheets maintain their appearance even with heavy use.

Tip: When you select surface treatments for color-coated sheets, consider both the visual effect and the level of protection you need. Each finish offers unique benefits for different environments.

Self-Cleaning

Features

You can choose self-cleaning color-coated sheets when you want surfaces that stay clean with minimal effort. These coated sheets use a special top layer that repels water and dust. When rain falls, it washes away dirt and debris from the surface. This feature keeps the coated sheets looking fresh and bright for a long time. The self-cleaning layer also helps prevent stains and reduces the need for frequent maintenance. You will notice that these color-coated sheets keep their color and gloss even in polluted or dusty environments. The technology behind self-cleaning coated sheets uses advanced coatings that break down organic matter under sunlight. This process helps you maintain a clean appearance with less work.

Applications

You can use self-cleaning color-coated sheets in places where cleanliness matters most. Many people install these coated sheets on building exteriors, especially in cities with high pollution. You will also find them on roofs, wall panels, and public facilities. Schools, hospitals, and shopping centers benefit from self-cleaning coated sheets because they reduce cleaning costs and keep buildings looking new. These color-coated sheets work well in areas with heavy rainfall, as the water helps clean the surface naturally.

Wrinkle

Features

Wrinkle surface color-coated sheets give you a unique textured look. The surface has a fine, wavy pattern that adds depth and style to the coated sheets. This texture helps hide fingerprints, scratches, and small dents. You will see that wrinkle finishes reduce glare and create a soft, elegant appearance. The coating process forms the wrinkle pattern during curing, making each sheet look distinct. Wrinkle color-coated sheets also offer good resistance to weather and fading.

Applications

You can use wrinkle color-coated sheets for both interior and exterior design. Many architects choose these coated sheets for modern buildings, decorative facades, and accent walls. You will also find wrinkle finishes in furniture, doors, and ceilings. The textured surface adds interest and style to any space. Wrinkle color-coated sheets work well in offices, hotels, and homes where you want a sophisticated look.

Suede

Features

Suede color-coated sheets provide a soft, velvety texture that feels pleasant to the touch. The surface mimics the look of real suede, giving you a luxurious and warm appearance. This finish reduces reflections and creates a cozy atmosphere. Suede coated sheets resist fingerprints and smudges, so they stay clean longer. The special coating also protects the sheets from moisture and fading.

Applications

You can use suede color-coated sheets in places where comfort and style matter. Many designers select these coated sheets for interior walls, ceilings, and decorative panels. You will see suede finishes in hotels, restaurants, and upscale homes. The soft texture makes these color-coated sheets ideal for spaces where people want a welcoming and elegant feel.

Tip: When you select surface treatments for color-coated sheets, think about the look, feel, and function you want for your project. Each finish offers unique benefits for different spaces.

Gold Sparkle

Features

You can choose gold sparkle surface treatments when you want coated sheets that stand out with a luxurious look. Gold sparkle finishes use special metallic pigments that create a shimmering effect. The surface catches the light and reflects it in different directions. This treatment gives coated sheets a rich, golden appearance that looks elegant and modern. You will notice that gold sparkle coated sheets resist fading and maintain their shine over time. Manufacturers use advanced coating technology to ensure the sparkle stays bright and does not wear off easily. The gold sparkle finish also adds a layer of protection, making the coated sheets more durable against scratches and stains.

Applications

You will find gold sparkle coated sheets in places where you want to create a sense of luxury or celebration. Many designers use these coated sheets for hotel lobbies, shopping malls, and high-end retail stores. You can install gold sparkle coated sheets on feature walls, ceilings, and decorative panels. Event venues often use this finish to add glamour to their interiors. Gold sparkle coated sheets work well for signage and branding elements because they attract attention. You can also use them in furniture design to create eye-catching pieces.

Silver Sparkle

Features

Silver sparkle surface treatments give coated sheets a bright, metallic shine. You get a finish that looks like polished silver, with tiny reflective particles that create a sparkling effect. The silver sparkle treatment uses high-quality pigments and resins to achieve a consistent, glossy surface. You will see that silver sparkle coated sheets resist tarnishing and keep their brilliance even in busy environments. The coating process ensures the sparkle is evenly distributed, so every sheet looks uniform. Silver sparkle coated sheets also offer good resistance to moisture and chemicals, which helps them last longer.

Applications

You can use silver sparkle coated sheets in modern architecture and interior design. Many people choose these coated sheets for office buildings, restaurants, and entertainment venues. Silver sparkle finishes work well for elevator panels, column covers, and decorative ceilings. You will find these coated sheets in exhibition halls and showrooms where you want to highlight products or displays. Silver sparkle coated sheets also suit furniture and cabinetry, adding a sleek, contemporary touch.

Copper-Like

Features

Copper-like surface treatments give coated sheets the warm, reddish-brown look of real copper. You get a finish that mimics the natural patina and shine of copper metal. The coating uses special pigments to create depth and variation in color. Copper-like coated sheets resist corrosion and maintain their appearance in different climates. The surface feels smooth and looks authentic, making it hard to tell apart from real copper. You will notice that copper-like coated sheets offer good protection against scratches and stains. Manufacturers use advanced technology to ensure the color stays true and does not fade quickly.

Applications

You can use copper-like coated sheets in architectural projects that need a classic or rustic look. Many designers select these coated sheets for building facades, roofing, and exterior wall panels. Copper-like finishes work well in restaurants, hotels, and cultural centers where you want to create a warm atmosphere. You will find copper-like coated sheets in decorative elements such as columns, railings, and signage. These coated sheets also suit furniture and interior accents, giving spaces a unique and timeless appeal.

Tip: When you select gold sparkle, silver sparkle, or copper-like surface treatments, you add personality and style to your project. Each finish offers a distinct look and lasting durability, making coated sheets a smart choice for creative designs.

| Surface Treatment | Visual Effect | Typical Uses | Durability Level |

|---|---|---|---|

| Gold Sparkle | Luxurious, bright | Hotels, malls, signage | High |

| Silver Sparkle | Modern, shiny | Offices, showrooms, panels | High |

| Copper-Like | Warm, classic | Facades, interiors, accents | High |

Wood Grain

Features

You can choose wood grain surface treatments for coated sheets when you want a natural and warm look. This finish uses advanced printing technology to create realistic wood patterns on the surface. You will see details like wood knots, grains, and color variations. The coated sheets look similar to real wood, but you get better durability and weather resistance. The wood grain finish resists fading and scratches. You can clean the surface easily. The coated sheets do not absorb moisture, so you avoid problems like warping or rotting. You can select from many wood styles, such as oak, cherry, or walnut. The finish stays bright and fresh for years.

Applications

You can use wood grain coated sheets in many places. Architects often choose them for building facades and exterior walls. You will see these coated sheets in residential homes, offices, and commercial buildings. Interior designers use wood grain finishes for ceilings, doors, and decorative panels. You can install coated sheets in kitchens and bathrooms because the surface resists water and stains. Furniture makers use wood grain coated sheets for cabinets and shelves. You get the beauty of wood with the strength of metal.

Tip: Wood grain coated sheets help you create a cozy and stylish space. You can match the finish to your design theme and enjoy easy maintenance.

Stone Grain

Features

Stone grain surface treatments give coated sheets the look of natural stone. You will notice patterns that mimic marble, granite, or slate. The finish uses special printing and embossing techniques. You get a textured surface that feels like real stone. The coated sheets resist scratches, stains, and fading. You do not need to worry about cracks or chips. The stone grain finish adds elegance and strength to your project. You can choose from many stone styles and colors. The coated sheets stay clean and bright even in harsh environments.

Applications

You can use stone grain coated sheets for exterior cladding and wall panels. Many people install them in shopping malls, hotels, and office buildings. You will see stone grain finishes in lobbies, elevators, and corridors. Designers use these coated sheets for columns and decorative accents. You can also use stone grain coated sheets in kitchens and bathrooms. The surface resists moisture and keeps its shine. You get the look of stone without the heavy weight or high cost.

Brick

Features

Brick surface treatments make coated sheets look like real brick walls. You will see detailed brick patterns and colors. The finish uses advanced printing to create a realistic effect. The coated sheets resist weather, stains, and scratches. You do not need to worry about crumbling or fading. The brick finish stays strong and bright for a long time. You can clean the surface easily. The coated sheets do not absorb water, so you avoid mold and damage.

Applications

You can use brick coated sheets for building exteriors and interior walls. Many architects choose them for schools, factories, and commercial buildings. You will see brick finishes in cafes, restaurants, and shops. The coated sheets work well for decorative panels and partitions. You can install brick coated sheets quickly and easily. You get the classic look of brick with the benefits of metal.

Note: Brick coated sheets help you create a timeless and sturdy appearance. You can use them in many settings and enjoy long-lasting performance.

Camouflage

Features

You can select camouflage surface treatments for coated sheets when you want a bold and creative look. This finish uses advanced printing technology to create patterns that blend with natural surroundings. You will see designs inspired by forests, deserts, or military themes. The camouflage effect makes coated sheets stand out in outdoor environments. The surface resists fading and scratches. You get a durable finish that keeps its color and pattern for years. Manufacturers use high-quality pigments to ensure the camouflage pattern stays sharp and vibrant.

- Camouflage patterns help you hide structures in nature.

- The finish provides extra protection against weather and UV rays.

- You can choose from different styles and colors to match your project.

Applications

You can use camouflage coated sheets in many outdoor settings. Builders often select them for cabins, hunting blinds, and storage units. You will see these coated sheets in parks, playgrounds, and military facilities. Camouflage finishes work well for temporary shelters and event booths. You can also use them for fencing and gates in gardens or forests. The unique look helps you blend structures into the landscape.

Tip: Camouflage coated sheets give you both style and function. You can create spaces that look natural and stay protected.

Grass

Features

Grass surface treatments give coated sheets a fresh and lively appearance. The finish uses special printing to mimic the look of real grass. You will notice green tones and soft patterns that resemble a grassy field. The surface resists stains and fading. You get a finish that stays bright and clean in outdoor conditions. Grass coated sheets use eco-friendly pigments to achieve a natural look.

- The grass pattern adds a playful touch to your project.

- The finish helps reduce glare and keeps surfaces cool.

- You can select different shades of green for your design.

Applications

You can use grass coated sheets in places where you want a cheerful and inviting atmosphere. Many people install them in playgrounds, schools, and parks. You will see these coated sheets on fences, walls, and decorative panels. Grass finishes work well for event spaces and garden structures. You can also use them for temporary installations at festivals or outdoor exhibitions.

Note: Grass coated sheets help you create fun and safe environments. You can brighten up any space with this unique finish.

Brushed Metal

Features

Brushed metal surface treatments give coated sheets a sleek and modern look. The finish uses mechanical brushing to create fine lines on the surface. You will see a subtle texture that reflects light in a soft way. The brushed effect makes coated sheets look elegant and professional. The surface resists fingerprints and scratches. You get a durable finish that stays clean and shiny. Manufacturers use advanced techniques to ensure the brushed pattern is consistent across all coated sheets.

| Feature | Benefit |

|---|---|

| Fine texture | Modern appearance |

| Scratch resistance | Long-lasting beauty |

| Easy cleaning | Simple maintenance |

Applications

You can use brushed metal coated sheets in many commercial and residential projects. Architects often choose them for office buildings, hotels, and restaurants. You will see these coated sheets on elevator panels, doors, and furniture. Brushed metal finishes work well for kitchen cabinets and appliances. You can also use them for signage and decorative accents in showrooms. The modern look fits many design styles.

Tip: Brushed metal coated sheets help you achieve a polished and contemporary space. You can enjoy both style and durability in your project.

3D

Features

You can choose 3D surface treatments for coated sheets when you want to create a striking visual effect. This finish uses advanced printing and embossing technology to give coated sheets a sense of depth and dimension. The surface does not stay flat. Instead, you see patterns that rise and fall, making the coated sheets look almost lifelike. You can select from geometric shapes, waves, or custom designs. The 3D effect makes colors appear richer and more dynamic. You will notice that light interacts with the surface in unique ways. Shadows and highlights change as you move around the coated sheets.

Manufacturers use special equipment to apply the 3D patterns. The process bonds the design tightly to the coated sheets, so the texture stays sharp and does not wear down easily. You get a finish that resists scratches and fading. The 3D surface also helps hide fingerprints and minor marks. Cleaning the coated sheets is simple. You can wipe the surface with a soft cloth to keep it looking fresh.

Tip: 3D coated sheets help you add personality to any space. You can use them to create a focal point or highlight a special area.

Applications

You will find 3D coated sheets in many creative projects. Architects use them for feature walls in offices, hotels, and shopping centers. The textured surface draws attention and makes spaces feel more interesting. You can install 3D coated sheets in lobbies, reception areas, and conference rooms. Designers often choose these coated sheets for ceilings and partitions. The 3D effect adds depth and style to interiors.

You can use 3D coated sheets in retail stores to showcase products. The unique surface helps displays stand out and attract customers. Event planners use 3D coated sheets for exhibition booths and stage backgrounds. The finish creates a dramatic look that fits many themes. You will also see 3D coated sheets in restaurants and cafes. The textured patterns make dining areas feel modern and inviting.

Some homeowners select 3D coated sheets for accent walls in living rooms or bedrooms. The surface brings energy and movement to home interiors. You can match the pattern and color to your personal style. Maintenance stays easy because the coated sheets resist stains and moisture.

Here is a quick table to help you see where you can use 3D coated sheets:

| Application Area | Benefit |

|---|---|

| Offices | Adds depth and interest |

| Retail Stores | Highlights products |

| Event Spaces | Creates dramatic backgrounds |

| Homes | Personalizes interiors |

Note: When you choose 3D coated sheets, you bring art and function together. The finish offers durability, easy care, and endless design possibilities.

Post-Processing of Color-Coated Sheets

When you explore coated sheets, you discover that post-processing adds new possibilities for design and function. You can select from perforated, orange peel, and diamond embossed finishes. Each type gives coated sheets unique properties that suit different industries and applications.

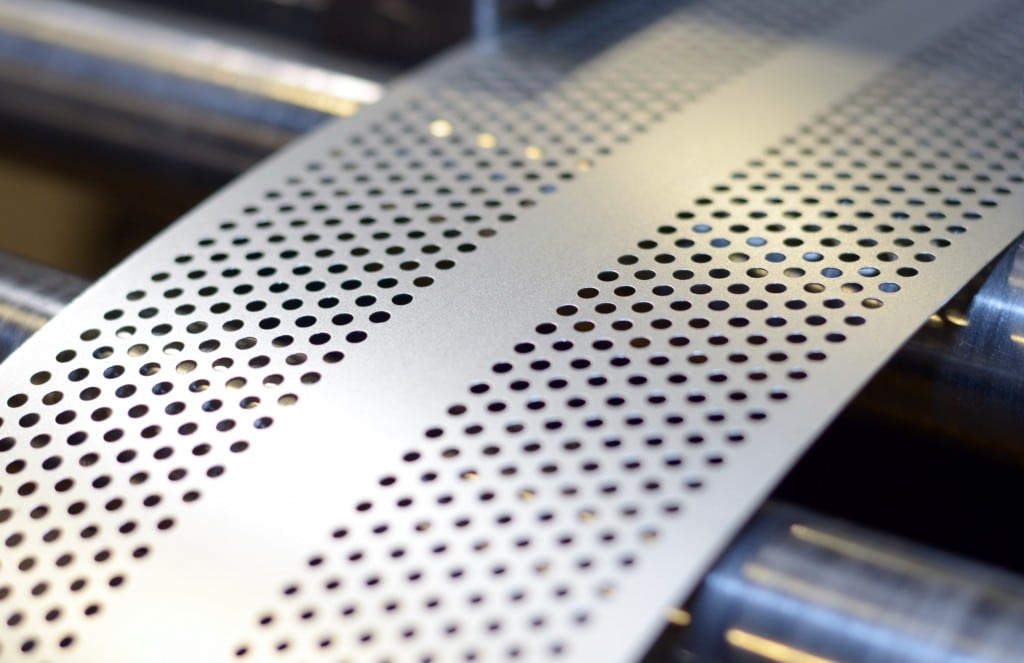

Perforated

Features

Perforated coated sheets feature a series of holes or patterns punched through the metal surface. You can choose from round, square, or custom shapes. The perforation process improves ventilation and reduces weight. You also gain better acoustic performance. The surface remains strong and durable because manufacturers use advanced techniques to maintain the integrity of coated sheets. You can select different hole sizes and arrangements to match your project needs.

Applications

You find perforated coated sheets in many industries. Construction uses them for facades, ceilings, and sunshades. Metalworking industries rely on these coated sheets for machine guards and filtration systems. The automotive industry selects perforated coated sheets for vehicle grilles and interior panels. Furniture makers use them to create modern designs for cabinets and shelves. The table below shows how different sectors use processed coated sheets:

| Industry Sector | Description |

|---|---|

| Construction | Utilizes pre-painted processed steel sheets for structural and aesthetic purposes. |

| Metalworking Industries | Employs these sheets for manufacturing various metal products. |

| Automotive Industry | Requires high durability materials for vehicle components. |

| Furniture Industry | Uses processed sheets for creating durable and appealing furniture. |

Tip: Perforated coated sheets help you combine style and function. You can improve airflow and create eye-catching designs at the same time.

Orange Peel

Features

Orange peel coated sheets have a textured surface that looks like the skin of an orange. You see small, raised bumps across the sheet. This finish hides fingerprints and minor scratches. The texture also reduces glare and adds a tactile feel. You can clean orange peel coated sheets easily because dust does not stick to the surface. The finish remains consistent and attractive over time.

Applications

You use orange peel coated sheets in places where durability and appearance matter. Many people install them in elevators, wall panels, and ceilings. The furniture industry selects orange peel coated sheets for cabinets and decorative panels. You also find these coated sheets in transportation vehicles and public spaces. The texture makes coated sheets safer and more comfortable to touch.

Note: Orange peel coated sheets give you a practical solution for busy environments. You can maintain a fresh look with minimal effort.

Diamond Embossed

Features

Diamond embossed coated sheets display a repeating diamond pattern pressed into the metal. You notice raised shapes that catch the light and create a three-dimensional effect. The embossing process strengthens coated sheets and improves slip resistance. You can select diamond embossed coated sheets for projects that need both style and safety. The pattern stays sharp and does not wear down easily.

Applications

You use diamond embossed coated sheets in flooring, stair treads, and ramps. Construction projects rely on these coated sheets for wall protection and decorative accents. The automotive industry installs diamond embossed coated sheets in truck beds and toolboxes. Furniture makers choose this finish for shelves and work surfaces. The diamond pattern helps prevent slipping and adds visual interest.

Tip: Diamond embossed coated sheets offer you a blend of safety and design. You can trust them for areas that need extra grip and durability.

You can select the right post-processing finish to match your needs. Perforated, orange peel, and diamond embossed coated sheets each provide unique benefits. You improve performance and style by choosing the best option for your project.

Durability and Fire Rating

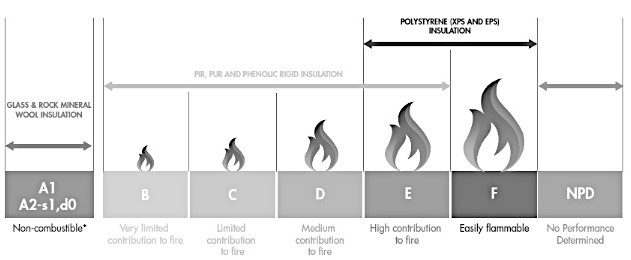

Fire Classification

Standards

You need to understand fire classification when you select coated sheets for your project. Fire ratings help you know how materials react to heat and flames. The most common standards include A1, A2-s1, d0. These ratings come from international fire safety codes. A1 means the coated sheets do not contribute to fire at all. A2-s1, d0 means the sheets have very limited combustibility and produce little smoke or droplets. You can check these ratings on product specifications before you buy.

| Fire Rating | Description | Typical Use Cases |

|---|---|---|

| A1 | Non-combustible | Hospitals, schools |

| A2-s1, d0 | Limited combustibility, low smoke | Offices, public spaces |

Tip: Always choose coated sheets with the right fire rating for your building type. This helps you meet safety regulations and protect people.

Applications

You will find coated sheets with high fire ratings in places where safety matters most. Builders use A1-rated coated sheets in hospitals, schools, and high-rise buildings. A2-s1, d0 sheets work well in offices, shopping centers, and public facilities. You can improve fire safety by matching the coated sheets to your project’s needs. Fire-rated coated sheets also help you get building permits faster.

Durability Comparison

By Material

You want coated sheets that last a long time and keep their appearance. The base material affects durability and service life. Aluminum coated sheets offer lightweight strength and resist rust. Galvanized steel coated sheets provide solid protection against corrosion. Galvalume coated sheets combine aluminum and zinc for extra durability in tough environments.

- Aluminum coated sheets: Lightweight, high corrosion resistance, long service life.

- Galvanized steel coated sheets: Strong, reliable, good for general construction.

- Galvalume coated sheets: Superior durability, ideal for coastal or industrial areas.

By Coating

The type of coating also changes how long coated sheets last. You can choose from several options. Fluoropolymer coatings, such as PVDF and FEVE, give coated sheets excellent durability and resistance in many environments. These coatings protect against UV rays, chemicals, and weather. Polyester coatings come in many varieties. Standard polyester resin works well for indoor and moderate outdoor use. Super polyester resin offers better durability and a longer service life for demanding projects.

| Coating Type | Durability Level | Best Use |

|---|---|---|

| PVDF/FEVE | Superior | Coastal, industrial |

| Super Polyester | Excellent | Outdoor, decorative |

| Standard Polyester | Good | Indoor, general |

Note: You should match the coating type to your environment. PVDF and FEVE coated sheets give you the longest service life and the best protection. Super polyester coated sheets also provide excellent durability for outdoor use.

You can extend the life of your coated sheets by choosing the right material and coating. This helps you save money and keep your building looking new.

Choosing the Right Color-Coated Sheet

Application Needs

You need to match coated sheets to your specific application scenarios. Each project has unique requirements. You should consider several factors before making a decision.

- Mechanical properties play a key role. You want coated sheets that can handle the stress and load of your project.

- The type of substrate matters. You must look at both the coating type and the weight of the base material.

- The performance of front and back coatings affects durability.

- Intended use guides your choice. For example, you may need coated sheets for roofing, wall panels, or furniture.

- Environmental conditions influence your selection. Humid, coastal, or industrial areas require higher corrosion resistance.

- Expected lifespan helps you plan for maintenance and replacement.

- Durability ensures your coated sheets last in demanding application scenarios.

- Processing methods and the level of deformation the material will undergo also impact your choice.

You should always review the application fields before selecting coated sheets. For outdoor projects, you need materials that resist weather and corrosion. Indoor projects may focus more on appearance and ease of cleaning.

Specification Comparison

You must compare technical specifications to find the best coated sheets for your needs.

- Thickness options vary. Some coated sheets offer a range from thin to thick, which helps you meet structural requirements.

- Corrosion resistance is important. You want coated sheets that stay strong in humid or aggressive environments.

- Weldability matters if you plan to join sheets for metal structures. Good weldability ensures strong joints and safe construction.

You can use a table to organize your comparison:

| Specification | What to Check | Why It Matters |

|---|---|---|

| Thickness | Range available | Fits structural needs |

| Corrosion Resistance | Type of coating, substrate | Withstands environment |

| Weldability | Welding practices | Ensures joint integrity |

You should review these details for each product. This helps you choose coated sheets that match your application scenarios and technical requirements.

Selection Tips

You can follow practical tips from industry experts to select the right coated sheets for your environment.

- Corrosion protection is essential. You should consider painting or galvanizing coated sheets in aggressive environments.

- Always match the coating type to your application scenarios. PVDF coatings work well in coastal areas. Polyester coatings suit indoor spaces.

- Check fire ratings for safety. Choose coated sheets with A1 or A2-s1, d0 ratings for public buildings.

- Review the expected lifespan and maintenance needs.

- Select coated sheets that fit your budget and design goals.

Tip: You improve your project’s performance and safety when you choose coated sheets based on application scenarios, specifications, and expert advice.

You now understand the key differences among color-coated sheets. Each type offers unique features for durability, appearance, and application. Use the comparison tables to match product benefits to your project needs.

- Choose based on environment, design, and required lifespan.

- Review gloss, surface treatment, and fire rating for best results.

Tip: Keep a quick checklist of your requirements. This helps you select the right sheet every time.

FAQ

What is the best color-coated sheet for coastal buildings?

You should choose PPGL or PVDF-coated sheets. These options offer excellent corrosion resistance and long-lasting color in salty, humid environments.

How do I select the right gloss level for my project?

Consider your design goals. Use matte or no gloss for a soft look. Choose semi-gloss or high gloss for a bright, modern finish.

Tip: Gloss level affects both appearance and cleaning ease.

Are color-coated sheets fire-resistant?

Yes, many color-coated sheets meet A1 or A2-s1, d0 fire ratings. You should check product specifications to ensure compliance with building safety standards.

Can I use color-coated sheets for furniture?

You can use HDP or brushed metal sheets for furniture. These finishes provide durability, easy cleaning, and stylish looks for cabinets, shelves, and panels.

What surface treatment hides scratches best?

Wrinkle, sand, and orange peel finishes help hide scratches and fingerprints. These textures keep your surfaces looking fresh in busy areas.

How do perforated sheets improve ventilation?

Perforated sheets have holes that allow air to pass through. You can use them for ceilings, facades, or machine guards to boost airflow and reduce weight.

Which coating lasts longest outdoors?

PVDF coatings last the longest outdoors. You get superior protection against UV rays, chemicals, and harsh weather.

| Coating Type | Outdoor Durability |

|---|---|

| PE | Good |

| SMP | Better |

| HDP | Excellent |

| PVDF | Superior |