A galvanized steel frame uses steel protected by a zinc coating to stop rust and damage. You rely on this frame in construction because it stands up to tough weather and heavy use. You get more than strength with this material.

- It resists corrosion and lasts for decades.

- You spend less time on maintenance.

- It looks modern and fits many designs.

- It supports sustainable building and works in many industries.

Key Takeaways

- Galvanized steel frames resist rust and corrosion due to a protective zinc coating, ensuring long-lasting durability.

- These frames require minimal maintenance, saving time and money on repairs and upkeep over the years.

- Galvanized steel offers a modern aesthetic that fits various design styles, enhancing the visual appeal of buildings.

- Using galvanized steel supports sustainable building practices, as it is highly recyclable and reduces waste.

- Galvanized steel frames provide strong structural support, making them ideal for both residential and commercial construction.

- Investing in galvanized steel frames leads to long-term cost savings, as they last longer and require fewer repairs compared to other materials.

- The ease of installation with galvanized steel frames speeds up construction projects, reducing labor costs and delays.

- Always ensure galvanized steel frames meet industry standards for quality and safety to guarantee performance and reliability.

Galvanized Steel Frame Explained

What Is a Galvanized Steel Frame

You see a galvanized steel frame in many modern buildings. This frame uses steel coated with zinc. The zinc layer protects the steel from rust and damage. You get a strong structure that stands up to harsh weather and heavy use. The frame works well in places where moisture and chemicals can cause problems. You find it in homes, factories, and bridges. The galvanized steel frame gives you a reliable base for many types of construction.

Here is a table showing the key physical and chemical properties that set galvanized steel frames apart from other steel frames:

| Property | Description |

|---|---|

| Corrosion Resistance | Enhanced due to magnesium addition, outperforming Galvalume in severe environments. |

| Coating Structure | Three-dimensional network that delays corrosion, effective on flat, cut-end, and scratched surfaces. |

| Performance in Corrosive Environments | Superior performance under severe conditions, forming a protective film that is less soluble in water. |

You benefit from these properties because they help your building last longer and stay safe.

Galvanized vs. Non-Galvanized Steel Frames

You may wonder how a galvanized steel frame compares to a non-galvanized steel frame. The main difference comes from the zinc coating. Galvanized steel has this extra layer, while non-galvanized steel does not. The coating acts as a shield against moisture and chemicals. You get better protection and longer life.

- Hot-dip galvanized steel can last over 50 years in ideal conditions. You see it used outdoors where corrosion is a big risk.

- Electro-galvanized steel has a thinner zinc layer. You find it indoors, but it does not last as long outside.

- Galvannealed steel offers good paint adhesion. It lasts less than hot-dip galvanized steel but still performs well with proper care.

Non-galvanized steel frames need more maintenance. You spend more time and money fixing rust and damage. Galvanized steel frames reduce these problems and give you peace of mind.

Why Galvanized Steel Is Used in Construction

You choose galvanized steel for construction because it stands up to tough conditions. Engineers pick galvanized steel frames for several reasons:

- Galvanized steel resists corrosion for years, even in harsh environments.

- The zinc coating delays rust, so your building stays strong.

- Galvanized wire and angle steel are stable and strong. You see fewer breaks and less downtime.

- You save money over time because you do not need frequent repairs.

- Galvanized steel allows longer intervals between maintenance, which is important in the construction industry and renewable energy projects.

Tip: When you use galvanized steel frames, you invest in durability and safety. You also make your project more cost-effective.

You see galvanized steel frames in many construction projects because they offer reliable protection, strength, and long-term value.

Galvanization Process for Steel Frames

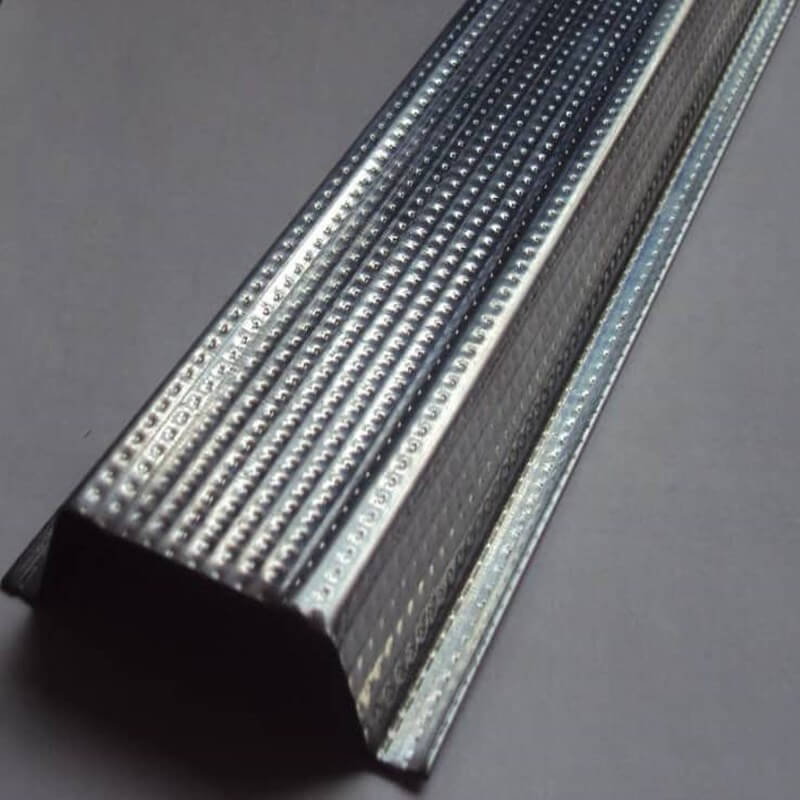

Hot-Dip Galvanizing

You often see hot-dip galvanizing as the main method for protecting steel frames. In this process, you dip steel parts into a bath of molten zinc. The zinc bonds to the steel, creating a thick, durable layer. This layer gives you strong corrosion protection and helps your frame last for decades. Hot-dip galvanizing works well for outdoor structures and places with high moisture. You get a coating thickness that ranges from 35 μm to 275 μm. This thick layer stands up to harsh weather and chemicals. When you choose hot-dipped galvanized steel, you invest in long-term durability and safety.

Electro-Galvanizing

Electro-galvanizing uses a different approach. You apply zinc to the steel using an electric current. This method creates a thinner zinc layer, usually between 5 μm and 15 μm. Electro-galvanizing gives you a smooth, even finish. You often use this process for indoor applications or where appearance matters more than heavy-duty protection. The thinner coating offers less corrosion protection than hot-dip galvanizing, so you should avoid using it in harsh outdoor environments. You still get some protection from rust, but the main benefit is the clean look and precise coating.

Here is a table that compares hot-dip galvanizing and electro-galvanizing:

| Method | Coating Thickness | Corrosion Resistance |

|---|---|---|

| Hot-Dip Galvanizing | Thicker (35 μm to 275 μm) | More resistant due to thicker zinc layer |

| Electro Galvanizing | Thinner (5 μm to 15 μm) | Less resistant due to thinner zinc layer |

Zinc Coating and Corrosion Protection

The zinc coating is the key to corrosion protection in galvanized steel frames. When you use the galvanizing process, you create a barrier that blocks moisture and chemicals from reaching the steel. The zinc also acts as a sacrificial layer. If the coating gets scratched, the zinc will corrode first, protecting the steel underneath. This self-healing property makes hot-dipped galvanized steel a smart choice for construction.

You can see the range of zinc coating thicknesses in different types of galvanized steel sheets:

| Type of Galvanized Steel Sheets | Zinc Coating Thickness (g/m2) |

|---|---|

| Hot-dip galvanized steel sheets | 60-1000 |

| Hot-dip galvannealed steel sheets | 30-120 |

| Hot-dip Zn-5% Al alloy-coated steel sheets | 60-250 |

| Hot-dip Zn-55% Al alloy-coated steel sheets | 60-200 |

| Hot-dip Zn-Al-Mg alloy-coated steel sheets | 60-450 |

| Double layered hot-dip galvannealed steel sheets | 3-6/20-60 |

| Electrogalvanized steel sheets | 3-50 |

| Electrolytic Zn-Ni or Fe or Co alloy-coated steel sheets | 10-40 |

| Prepainted hot-dip galvanized steel sheets with organic resin | 25-200μm/60-300 |

| Prepainted electrogalvanized steel sheets with organic film | 1μm/20-30 |

Note: Thicker zinc coatings give you better corrosion protection and longer service life. Hot-dipped galvanized steel usually offers the best results for outdoor and industrial use.

When you select the right galvanization method, you ensure your steel frame gets the protection it needs. You reduce maintenance, extend the lifespan of your structure, and keep your investment safe from rust and damage. The galvanizing process remains a reliable way to achieve strong corrosion protection and lasting performance.

Industry Standards for Galvanized Steel

When you choose galvanized steel frames for your project, you want to make sure they meet strict quality and safety standards. Industry standards help you know that the steel you use will perform as expected. These standards set clear rules for how manufacturers should produce, test, and label galvanized steel products.

You will find several important organizations that create and maintain these standards. Some of the most recognized groups include:

- ASTM International (American Society for Testing and Materials)

- ISO (International Organization for Standardization)

- BSI (British Standards Institution)

- JIS (Japanese Industrial Standards)

Each group publishes documents that tell you exactly how to measure coating thickness, test for corrosion resistance, and check the quality of the zinc layer. For example, ASTM A123 is a common standard in the United States for hot-dip galvanized steel products. It covers everything from the minimum zinc coating thickness to inspection methods.

Here is a table showing some key standards you might see:

| Standard Name | Organization | What It Covers |

|---|---|---|

| ASTM A123 | ASTM | Hot-dip galvanizing of iron and steel products |

| ASTM A153 | ASTM | Galvanizing of hardware items |

| ISO 1461 | ISO | Hot-dip galvanized coatings on fabricated iron and steel articles |

| BS EN ISO 14713 | BSI/ISO | Protection against corrosion of iron and steel in structures |

| JIS H 8641 | JIS | Hot-dip zinc coatings |

You should always check that your galvanized steel frames meet the right standards for your region and project type. When you see a product labeled with a standard like ASTM A123 or ISO 1461, you know it has passed specific tests for coating thickness, adhesion, and corrosion resistance.

Tip: Ask your supplier for certification or test reports. This helps you confirm that the steel frames meet the required standards and will last as long as you expect.

Industry standards also help you compare products from different manufacturers. You get a clear idea of what to expect in terms of quality and performance. If you skip these standards, you risk using steel that may not protect your building from rust or damage.

By following industry standards, you make your construction project safer and more reliable. You also avoid costly repairs and replacements in the future. Always look for galvanized steel frames that meet or exceed the recognized standards. This simple step gives you peace of mind and helps your building stand the test of time.

Benefits of Galvanized Steel in Construction

Corrosion Resistance

You want your building to last, so you need materials that fight off rust and decay. Galvanized steel gives you outstanding corrosion resistance. The zinc coating on galvanized steel acts as a shield, blocking moisture and chemicals from reaching the steel underneath. This barrier keeps your building strong, even in harsh environments with lots of rain or salt in the air.

Galvanized steel stands out when you compare it to other protective coatings. The zinc layer not only forms a physical barrier but also provides sacrificial protection. If the coating gets scratched, the zinc will corrode first, saving the steel from damage. This feature makes galvanized steel a top choice for light steel framing in construction projects where rust resistance is critical.

| Feature | Galvanized Steel | Other Coatings |

|---|---|---|

| Initial Cost | Low | Varies |

| Durability | Outstanding | Varies |

| Maintenance | Low to Zero | Higher |

| Resistance to Damage | High | Varies |

| Longevity | 20-100 years | Varies |

You see that galvanized steel offers a unique set of advantages. It protects your building for decades, often outlasting other coatings. This level of corrosion resistance means you can trust your light steel framing to hold up in any building system.

Tip: Galvanized coatings can last from 20 to 100 years, depending on the environment. This makes galvanized steel a smart investment for any building.

Durability and Longevity

When you choose galvanized steel for your building, you get more than just protection from rust. You gain the durability of galvanized steel, which means your structure can handle heavy loads, impacts, and daily wear. Light steel framing made from galvanized steel keeps its strength over time, even when exposed to tough weather or chemicals.

Galvanized steel frames do not warp, crack, or shrink like some other materials. You can rely on them to keep your building safe and stable for many years. The durability and longevity of galvanized steel make it ideal for both residential and commercial construction. You see these frames in schools, warehouses, and even bridges because they stand the test of time.

Galvanized steel’s lifespan can reach up to 100 years in the right conditions. This long service life means you do not have to worry about frequent replacements. Your building system stays strong, and you save money in the long run.

Low Maintenance

You want to spend less time and money on building upkeep. Galvanized steel helps you achieve that goal. The zinc coating on light steel framing means you do not need to paint or treat the steel regularly. You avoid the hassle of constant inspections and repairs.

Galvanized steel frames resist rust, so you do not have to deal with flaking paint or corroded parts. This low maintenance feature is a major advantage for busy building owners and managers. You can focus on other tasks, knowing your building will stay in good shape with minimal effort.

- You save on labor costs because maintenance needs are low.

- You reduce downtime since repairs are rare.

- You avoid expensive treatments that other materials require.

Note: Galvanized steel’s low maintenance needs make it perfect for light steel framing in large buildings, factories, and public spaces.

By choosing galvanized steel, you ensure your building remains safe, attractive, and cost-effective for years to come.

Cost Savings Over Time

You want to make smart choices for your construction budget. Galvanized steel frames help you save money in several ways. The zinc coating protects the steel, so you do not need to pay for frequent repairs or replacements. You avoid the cost of painting and treating the steel every few years. You also spend less on labor because maintenance is simple and quick.

Here are the main ways galvanized steel frames save you money:

- Lower Maintenance Costs: You do not need to hire workers for regular rust removal or repainting.

- Longer Lifespan: You avoid the expense of replacing frames that fail early.

- Fewer Repairs: You spend less on fixing damage caused by corrosion.

- Reduced Downtime: You keep your building open and working, which helps your business.

Tip: When you choose galvanized steel, you invest in a material that pays off for decades. The upfront cost may be higher than some alternatives, but the long-term savings make it a smart decision.

Here is a table that compares the estimated costs over 30 years for different framing materials:

| Material | Initial Cost | Maintenance Cost | Replacement Cost | Total Cost Over 30 Years |

|---|---|---|---|---|

| Galvanized Steel | Medium | Low | Low | Low |

| Non-Galvanized Steel | Low | High | Medium | High |

| Wood | Low | Medium | High | High |

| Aluminum | High | Low | Medium | Medium |

You see that galvanized steel offers the lowest total cost over time. You protect your investment and keep your project on budget.

Aesthetic Appeal

You want your building to look modern and attractive. Galvanized steel frames give you a clean, sleek appearance that fits many design styles. The zinc coating creates a shiny, silver finish that stands out in both commercial and residential projects. You can leave the steel exposed for an industrial look or paint it to match your design.

Galvanized steel works well with glass, concrete, and other materials. You get a contemporary look that appeals to architects and clients. The surface stays bright and smooth for years, even in tough environments.

- You can use galvanized steel for visible beams, columns, and railings.

- You can combine it with other materials for a unique style.

- You can choose different finishes, such as matte or glossy, to suit your taste.

Note: Galvanized steel does not fade or stain easily. You keep your building looking fresh with minimal effort.

Ease of Installation

You want your construction project to move quickly and smoothly. Galvanized steel frames help you achieve this goal. The frames arrive ready to use, so you do not need to treat or coat them on site. You save time and avoid delays.

Galvanized steel is lightweight compared to some other materials. You can lift and position the frames with less effort. The frames fit together easily, which speeds up assembly. You can use standard tools and fasteners, so you do not need special equipment.

Here are some reasons why installation is easier with galvanized steel:

- You get consistent sizes and shapes, which makes planning simple.

- You avoid waiting for coatings to dry or cure.

- You reduce the risk of mistakes because the frames are pre-finished.

Alert: Fast installation means lower labor costs and fewer disruptions to your schedule.

You finish your project faster and start using your building sooner. Galvanized steel frames make construction efficient and reliable.

Applications in Construction and Infrastructure

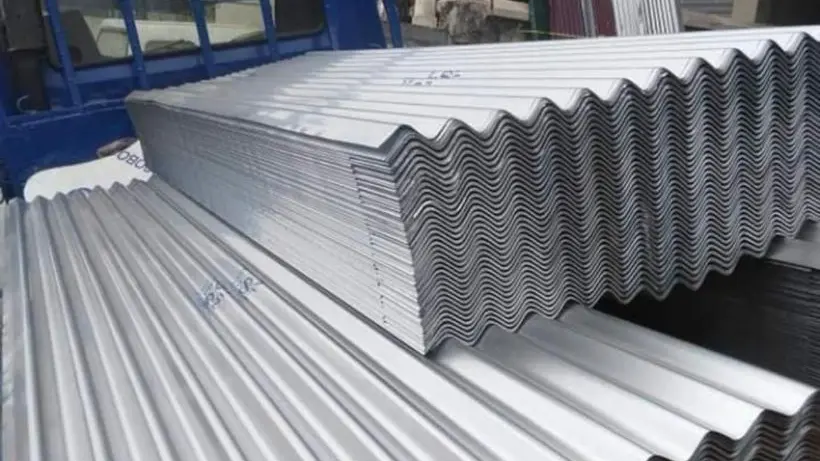

Roofing and Wall Panels

You see galvanized steel frames used in roofing and wall panels across many infrastructure projects. These panels protect buildings from rain, wind, and temperature changes. Galvanized steel offers excellent resistance to corrosion, which is vital for surfaces exposed to weather. This property helps maintain the structural integrity of buildings and reduces the need for frequent repairs. You benefit from lower maintenance costs and improved building performance. The common uses of galvanized steel in roofing and wall panels include warehouses, schools, and stadiums. You also find these panels in residential homes and commercial offices. The material’s durability makes it a top choice for construction and infrastructure projects that demand long-lasting protection.

Structural Framing

You rely on galvanized steel frames for structural support in many types of buildings. The common uses of galvanized steel in framing include apartment complexes, office buildings, museums, and sports arenas. You get strong support structures that resist corrosion and stand up to heavy loads. Galvanized steel frames provide high strength, which is essential for large-scale infrastructure. You can see the advantages in the table below:

| Structural Advantage | Description |

|---|---|

| High-Strength Galvanized Steel | Provides superior resistance to corrosion, ensuring a long service life in harsh environments. |

| Wind and Earthquake Resistance | Capable of withstanding high winds (up to level 10) and earthquakes (up to level 7). |

| Precision Engineering | Features precision-cut components for easy assembly and disassembly without compromising integrity. |

| Insulation Integration | Seamlessly integrates advanced insulation materials for superior thermal performance. |

You notice that galvanized steel frames offer reliability and versatility in construction and infrastructure. You can assemble and disassemble these frames quickly, which helps with modular designs and future renovations. The common uses of galvanized steel in structural framing make it a preferred material for both residential and commercial projects.

Fencing and Barriers

You often choose galvanized steel for fencing and barriers in public infrastructure. The common uses of galvanized steel include highway guardrails, security fences, and barriers around parks or schools. Galvanized steel resists corrosion, especially in harsh environments like coastal areas. You get fences and barriers that last longer and require less maintenance. The table below shows how galvanized steel improves durability:

| Evidence Description | Benefit to Durability |

|---|---|

| Galvanized steel resists corrosion, especially in harsh environments like coastal air. | Enhances longevity and reduces maintenance needs. |

| Proper installation and maintenance are crucial for maximizing the lifespan of steel. | Ensures structural integrity over time. |

| Regular inspections and touch-ups can prolong the life of steel fencing. | Maintains functionality and appearance, preventing decay. |

You see the common uses of galvanized steel in fencing and barriers because it provides reliable protection for infrastructure. You keep public spaces safe and attractive while reducing long-term costs. Galvanized steel frames prove their value in construction and infrastructure by offering solutions that last.

Modular and Temporary Structures

You often see galvanized steel frames in modular and temporary structures. These structures need to be strong, quick to assemble, and easy to move. Galvanized steel gives you all these benefits. You can use these frames for many types of projects, from construction sites to emergency shelters.

You get several advantages when you choose galvanized steel for modular buildings:

- Fast Assembly: You can put together galvanized steel frames quickly. The parts arrive ready to use. You do not need to wait for coatings to dry or for special treatments.

- Portability: You can move modular structures from one location to another. The steel frames stay strong during transport. You do not have to worry about rust or damage.

- Flexibility: You can change the layout or size of your structure. Galvanized steel frames let you add or remove sections with ease.

- Reusability: You can use the same frames for different projects. The zinc coating keeps the steel in good shape, even after many uses.

Tip: If you need a building for a short time, galvanized steel frames help you save money. You can take the structure down and use it again later.

Here are some common examples of modular and temporary structures that use galvanized steel frames:

| Structure Type | Typical Use Cases | Key Benefit of Galvanized Steel |

|---|---|---|

| Site Offices | Construction sites, mining camps | Quick setup, easy relocation |

| Emergency Shelters | Disaster relief, refugee camps | Fast deployment, weather resistance |

| Exhibition Booths | Trade shows, fairs, events | Reusable, attractive appearance |

| Portable Classrooms | Schools, training centers | Durable, safe for students |

| Temporary Housing | Festivals, remote work sites | Comfortable, long-lasting |

You can see that galvanized steel frames work well in many situations. You get a structure that stands up to wind, rain, and daily use. You also get a building that looks modern and professional.

You do not need to spend much time on maintenance. The zinc coating protects the steel from rust, even if you move the structure often. You can trust these frames to last through many projects.

Note: Modular and temporary structures made with galvanized steel frames support green building practices. You reduce waste because you can reuse the frames. You also lower your costs over time.

You make a smart choice when you use galvanized steel frames for modular and temporary structures. You get strength, flexibility, and value in every project.

Comparing Framing Materials

Galvanized Steel Frame vs. Non-Galvanized Steel

You often choose between galvanized and non-galvanized steel for your building projects. Galvanized steel has a zinc coating that protects it from rust and damage. Non-galvanized steel does not have this protection. You see the difference in how each material performs over time.

- Galvanized steel lasts longer in wet or harsh environments.

- Non-galvanized steel needs more maintenance to prevent rust.

- You spend less money on repairs when you use galvanized steel.

Here is a table that shows how these two materials compare:

| Feature | Galvanized Steel | Non-Galvanized Steel |

|---|---|---|

| Corrosion Resistance | High | Low |

| Maintenance Needs | Low | High |

| Lifespan | Long | Short |

| Cost Over Time | Lower | Higher |

Tip: If you want a frame that stands up to weather and lasts for years, galvanized steel is the better choice.

Galvanized Steel vs. Wood Frames

You may wonder how galvanized steel compares to wood frames. Wood is a common building material, but it has some drawbacks. Steel offers more strength and durability.

- Steel does not rot or attract insects.

- Wood can warp, crack, or get damaged by moisture.

- You get a stronger structure with steel, especially for large buildings.

Here are some points to consider:

- Steel resists fire better than wood.

- You do not need to treat steel for pests.

- Wood frames may cost less at first, but steel saves you money in the long run.

Note: Steel frames are ideal for places with high humidity or risk of termites.

Galvanized Steel vs. Aluminum Frames

You also see aluminum used for frames in construction. Aluminum is light and does not rust easily. Steel is stronger and can handle heavier loads.

- Steel costs less than aluminum for most projects.

- Aluminum is easier to shape but may bend under heavy weight.

- You get better support with steel in large structures.

Here is a quick comparison:

| Feature | Galvanized Steel | Aluminum |

|---|---|---|

| Strength | High | Medium |

| Weight | Heavier | Lighter |

| Cost | Lower | Higher |

| Corrosion Resistance | High | High |

| Best Use | Large buildings | Small structures |

Alert: Choose steel when you need a frame that supports heavy loads and lasts for decades.

You can see that each material has its own strengths. You should pick the one that fits your project’s needs. Galvanized steel gives you a strong, long-lasting frame that works well in many types of construction.

Addressing Misconceptions

Environmental Considerations

You may wonder how galvanized steel frames affect the environment. Many people think steel production always harms nature, but you can see positive changes in the industry. Today, steel makers focus on using resources wisely and recycling as much as possible.

- You help the planet when you choose galvanized steel because steel is one of the most recycled materials in the world. The recycling rate for steel reaches 93.7%. This number is much higher than for many other building materials.

- You support a circular economy when you use galvanized steel frames. Companies like the JFE Group turn byproducts and waste into new resources. This process reduces the need for raw materials and cuts down on landfill waste.

- You also help save water. The steel industry works hard to use less water and recycle it during production. This effort protects water supplies and lowers the impact on the environment.

Tip: When you select galvanized steel frames, you choose a material that supports sustainability and resource efficiency. You make a smart choice for both your project and the environment.

You can feel confident that galvanized steel frames offer strong environmental benefits. You support recycling, reduce waste, and help conserve water. These actions make a real difference in building a greener future.

Limitations and Drawbacks

You gain many benefits from galvanized steel frames, but you should also know about their limitations and drawbacks. Understanding these helps you make better decisions for your construction projects.

1. Initial Cost Can Be Higher

You may notice that galvanized steel frames often cost more upfront than non-galvanized steel or wood. The galvanizing process adds to the price. If you have a tight budget, this higher initial cost might concern you. However, you often save money over time because of lower maintenance and longer lifespan.

2. Weight and Handling

Galvanized steel frames weigh more than aluminum or wood. You need special equipment to move and install them, especially for large projects. This extra weight can increase transportation costs and make installation slower.

3. Limited Flexibility for On-Site Changes

Once manufacturers apply the zinc coating, making changes or cutting the steel on-site becomes difficult. If you cut or weld galvanized steel, you risk damaging the protective layer. You may need to reapply zinc-rich paint or coatings to protect exposed areas. This adds extra steps and can slow down your project.

4. Appearance Over Time

Galvanized steel starts with a shiny, silver finish. Over time, the surface can become dull or develop a whitish coating called “white rust,” especially in humid conditions. While this does not usually affect strength, it can change the look of your building.

5. Environmental and Health Concerns During Fabrication

When you weld or cut galvanized steel, you may release zinc fumes. These fumes can be harmful if you breathe them in. You must use proper ventilation and safety gear to protect yourself and your team.

Here is a quick table to help you compare some key drawbacks:

| Limitation | Impact on Your Project |

|---|---|

| Higher Initial Cost | Increases upfront spending |

| Heavy Weight | Needs special handling and equipment |

| Hard to Modify On-Site | Requires extra steps for repairs |

| Surface Changes Over Time | May affect building appearance |

| Zinc Fume Risk | Needs safety measures during fabrication |

Note: No building material is perfect. You should weigh these drawbacks against the many benefits of galvanized steel. If you plan ahead and use the right safety practices, you can manage most of these challenges.

You make the best choice when you understand both the strengths and the weaknesses of galvanized steel frames.

Why Galvanized Steel Frames Are Essential

Meeting Modern Construction Needs

You face new challenges in construction every year. You need materials that keep up with changing codes and standards. Galvanized steel frames help you meet these demands. The zinc coating protects steel from rust, even if the surface gets scratched. You can rely on these frames to stay strong and corrosion-free for decades. This durability means your building will last longer and require fewer repairs.

You see galvanized steel used in many industries. It supports buildings, bridges, and even vehicles. The adaptability of steel makes it a smart choice for modern projects. You can use it for outdoor structures because it resists harsh weather. You also benefit from its long lifespan, which matches the expectations of today’s construction standards.

- Galvanized steel frames keep buildings strong for years.

- The zinc coating allows the steel to withstand minor damage.

- You get reliable support for large and small projects.

Safety and Compliance

You want your building to be safe and meet all regulations. Galvanized steel frames help you achieve this goal. The strength of steel provides solid support for walls, roofs, and floors. You reduce the risk of structural failure when you choose galvanized steel. The zinc coating also helps your building pass inspections for corrosion resistance.

Modern construction codes require materials that last and protect people inside. Galvanized steel meets these standards. You avoid frequent repairs, which keeps your building safe for everyone. You also lower the chance of accidents caused by weak or damaged frames.

Tip: Always check that your steel frames meet industry standards like ASTM or ISO. This ensures your project stays compliant and safe.

Long-Term Value

You want your investment to pay off over time. Galvanized steel frames offer long-term value for any construction project. The zinc coating reduces maintenance costs and extends the life of your building. You spend less money on repairs and replacements. You also save time because galvanized steel needs little upkeep.

Here is a table that shows how galvanized steel frames provide value compared to other materials:

| Feature | Galvanized Steel Frames | Other Materials |

|---|---|---|

| Lifespan | Decades | Shorter |

| Maintenance | Minimal | Frequent |

| Cost Over Time | Lower | Higher |

| Reliability | High | Varies |

You see that galvanized steel frames help you build structures that last. You get strong support, safety, and savings for years to come. This makes galvanized steel an essential part of modern construction.

You see that galvanized steel frames give your projects strength, long life, and a modern look. You save money over time because you do not need much maintenance. These frames resist rust and damage, so your building stays safe. If you want a reliable and cost-effective solution, choose galvanized steel frames for your next construction project.

Tip: Galvanized steel frames help you build smarter and safer every time.

FAQ

What is the main advantage of using galvanized steel frames?

You get strong protection against rust and corrosion. The zinc coating keeps your frame safe in harsh weather. This means your building lasts longer and needs less maintenance.

Can you paint over galvanized steel frames?

Yes, you can paint over galvanized steel. Clean the surface first. Use a primer made for galvanized metal. This helps the paint stick and last longer.

How long do galvanized steel frames last?

You can expect galvanized steel frames to last 20 to 100 years. The lifespan depends on the environment and the thickness of the zinc coating.

Are galvanized steel frames safe for indoor use?

Yes, you can use galvanized steel frames indoors. They do not release harmful chemicals. You get a safe and strong structure for homes, offices, or schools.

Do galvanized steel frames require special maintenance?

You do not need much maintenance. Check for scratches or damage. Clean the surface if needed. The zinc coating protects the steel, so you spend less time on upkeep.

Can you recycle galvanized steel frames?

Yes, you can recycle galvanized steel. Steel is one of the most recycled materials in the world. Recycling helps save resources and supports green building.

Are galvanized steel frames fire-resistant?

You get good fire resistance with galvanized steel frames. Steel does not burn. The zinc coating does not add fuel to a fire. This makes your building safer.

What types of buildings use galvanized steel frames?

You find galvanized steel frames in homes, factories, bridges, schools, and temporary structures. They work well in many types of construction because they are strong and reliable.