A galvanized steel strap gives you reliable strength for securing heavy loads and structural elements. Manufacturers coat these straps with zinc, which protects against rust and damage. You benefit from long-lasting durability, especially in construction, plumbing, HVAC, and packaging. When you use a galvanized steel strap, you choose a solution that resists corrosion and handles high tension in demanding environments.

Key Takeaways

- Galvanized steel straps provide strong support and resist rust, making them ideal for construction, plumbing, HVAC, and packaging.

- The zinc coating on these straps protects against moisture, ensuring long-lasting durability in harsh environments.

- Choose the right type of strap: perforated for flexibility and easy installation, solid for maximum strength in heavy-duty tasks.

- Galvanized steel straps are cost-effective, offering lower initial prices and reduced maintenance needs compared to alternatives like stainless steel.

- Always check the weight rating and specifications before using a strap to ensure safety and stability for your project.

- Galvanized steel straps are versatile and can be used for bundling, securing, and reinforcing materials in various applications.

- For outdoor projects, galvanized steel straps provide extra protection against the elements, ensuring your structures remain stable over time.

- Buying galvanized steel straps in bulk can save you money, as suppliers often offer discounts for larger orders.

Galvanized Steel Strap Overview

Definition and Purpose

You use a galvanized steel strap when you need a strong, flexible band to secure, support, or fasten materials. This strap consists of steel that has a protective zinc coating. The main purpose is to provide reliable support in environments where moisture or harsh conditions might cause rust. You often find this product in construction, plumbing, HVAC, and packaging because it holds up well under pressure and resists damage.

Key Features

Zinc Coating

The zinc coating sets a galvanized steel strap apart from regular steel straps. Manufacturers apply a layer of zinc to the steel surface. This coating acts as a barrier, keeping water and air from reaching the steel underneath. You get extra protection, which means the strap lasts longer and stays strong even in damp or outdoor settings.

Corrosion Resistance

You want a strap that can handle tough conditions. The zinc layer gives the galvanized steel strap excellent corrosion resistance. Rust can weaken steel over time, but the zinc coating stops this process. You can use these straps outside, in basements, or anywhere moisture is a concern. They keep their strength and shape, so you do not have to worry about sudden failures.

Tip: Choose galvanized steel straps for projects where you need both strength and protection from rust. This choice helps you avoid costly repairs or replacements later.

Here are some features that make galvanized steel straps stand out from other types:

- You get a balance of light weight and high strength, which makes handling and installation easier.

- The long service life means you do not need to replace straps as often.

- Galvanized steel straps cost less than stainless steel or copper options, so you save money on your project.

Sold by Weight

You usually buy galvanized steel straps by weight instead of by length. This method helps you get the right amount for your project, whether you need a small roll for a quick repair or a large batch for a construction site. The weight-based system also makes it easier to compare prices and plan your budget.

Manufacturing Process

Galvanization Methods

When you choose a galvanized steel strap, you benefit from a specialized manufacturing process. The process starts with steel, which receives a protective zinc coating. You can find two main methods for galvanizing steel straps: hot-dip galvanizing and electro-galvanizing.

Hot-Dip

Hot-dip galvanizing gives you a thick, durable layer of zinc. Manufacturers immerse steel straps in a bath of molten zinc. The zinc bonds to the steel surface, creating a tough barrier. You get a strap that stands up to harsh weather and moisture. Hot-dip galvanized straps work well for outdoor projects, construction sites, and places where you expect heavy exposure to the elements.

Note: Hot-dip galvanizing often leaves a slightly rough texture and a shiny, spangled finish. This look helps you identify the process and gives extra grip for certain applications.

Electro-Galvanizing

Electro-galvanizing uses an electric current to apply a thinner layer of zinc to the steel. You get a smoother finish and a more uniform appearance. Electro-galvanized straps suit indoor projects, packaging, and electrical work. The process works best when you need a clean look and moderate protection from rust.

| Method | Zinc Layer Thickness | Surface Finish | Best Use Cases |

|---|---|---|---|

| Hot-Dip | Thick | Rough/Shiny | Outdoor, heavy-duty, exposed |

| Electro-Galvanizing | Thin | Smooth | Indoor, light-duty, packaging |

Strength and Durability

You want steel straps that last and perform under pressure. The galvanization process gives you that advantage. When manufacturers coat steel with zinc, they create a shield against moisture and air. This shield stops rust and corrosion before it starts.

Galvanized steel straps keep their tensile strength over time. You can rely on them for demanding jobs, such as securing heavy loads or reinforcing structures. Non-galvanized steel straps lose strength as rust eats away at the metal. Galvanized straps maintain their integrity, so you avoid sudden failures and costly repairs.

- You get longer service life for your projects.

- You reduce maintenance needs and replacement costs.

- You improve safety by using straps that resist damage.

Tip: Always check the type of galvanization before you buy. Hot-dip offers maximum protection for outdoor use. Electro-galvanizing works best for indoor or decorative needs.

Galvanized steel straps give you a smart choice for strength, durability, and reliability. You can trust them to hold up in tough environments and keep your materials secure.

Types of Galvanized Steel Straps

When you choose a galvanized steel strap, you have several types to consider. Each type serves a different purpose and fits specific project needs. Understanding these options helps you pick the right strap for your job.

Perforated vs. Solid

You will see two main styles: perforated and solid. Perforated straps have evenly spaced holes along their length. These holes let you use screws, bolts, or nails for easy attachment. You can adjust the strap to fit around pipes, beams, or other objects. Perforated straps work well for hanging pipes, supporting ductwork, or securing cables.

Solid straps do not have holes. You get a continuous band of steel. This type gives you maximum strength and support. You often use solid straps for heavy-duty tasks, such as reinforcing structures or bundling large materials. Solid straps resist bending and stretching, so they hold up under high tension.

Tip: Use perforated straps when you need flexibility and easy installation. Choose solid straps for projects that demand extra strength.

| Type | Key Feature | Best Use Case |

|---|---|---|

| Perforated | Pre-drilled holes | Pipe hanging, cable support |

| Solid | No holes | Structural reinforcement |

Size Variations

You can find galvanized steel straps in many sizes. Width, thickness, and length all vary. The right size depends on your project. For light jobs, such as securing small pipes, you might use a narrow, thin strap. For heavy loads, you need a wider and thicker strap.

- Width: Common widths range from 1/2 inch to 2 inches.

- Thickness: Most straps measure between 18 and 22 gauge.

- Length: Rolls can be as short as 10 feet or as long as 100 feet.

Choosing the correct size ensures safety and stability. If you use a strap that is too thin, it may break under pressure. If you pick one that is too wide, it may not fit your space.

Note: Always check the weight rating and recommended use before you buy a strap.

Specialty Straps

Some projects require specialty galvanized steel straps. Manufacturers design these straps for unique tasks or environments. You might see heavy-duty straps with extra-thick zinc coatings for marine or outdoor use. Some straps come with a rubber or plastic coating for added protection against abrasion.

Other specialty straps include:

- Pre-cut lengths: Save time on installation.

- Custom shapes: Fit around odd angles or corners.

- Color-coded finishes: Help you identify strap types quickly.

You can also find straps with extra corrosion resistance for chemical plants or coastal areas. Specialty straps give you more options when standard straps do not meet your needs.

Alert: Specialty straps may cost more, but they offer better performance for challenging jobs.

When you know the types of galvanized steel straps, you can match the right product to your project. This choice helps you work faster, safer, and with better results.

Galvanized Steel Strap Uses

Construction

Framework Reinforcement

You rely on a galvanized steel strap when you need to reinforce frameworks in buildings and structures. This strap helps you secure beams, joists, and other load-bearing elements. You can wrap the strap around materials with sharp edges and hard corners, such as I-beams and steel plates. The zinc coating protects the steel from moisture, so your framework stays strong over time. You maintain rigidity for loads that will not settle, which keeps your structure safe and stable.

Securing Scaffolding

You use galvanized steel straps to secure scaffolding on construction sites. These straps hold pipes and metal bars together, so your scaffolding remains steady while you work. The corrosion resistance of the strap means you can use it outdoors without worrying about rust. You get peace of mind knowing your scaffolding will not fail due to weakened fasteners.

Attaching Structural Elements

You attach structural elements with galvanized steel straps in many building projects. The strap binds components together, such as in highway guardrail installations. You can fasten metal panels, connect support columns, or join sections of framing. The strength and flexibility of the strap make it easy to adjust and tighten as needed. You avoid problems with shifting or loosening parts, which helps you complete your project efficiently.

Tip: Choose the right strap size for your construction job. Wider and thicker straps give you more support for heavy materials.

Common construction uses for galvanized steel straps include:

- Holding materials with sharp edges and hard corners, like I-beams and steel plates

- Maintaining rigidity for loads that will not settle over time

- Binding components together in highway guardrail installations

Plumbing and HVAC

Pipe Support

You support pipes in plumbing and HVAC systems with galvanized steel straps. The strap wraps around pipes and secures them to walls, ceilings, or floors. You prevent pipes from sagging or shifting, which reduces the risk of leaks. The zinc coating protects the strap from moisture, so you can use it in basements, crawl spaces, or outdoor areas.

Hanging Ductwork

You hang ductwork for heating, ventilation, and air conditioning with galvanized steel straps. The strap holds ducts in place and keeps them aligned. You can adjust the strap to fit different duct sizes and shapes. The corrosion resistance ensures your duct supports last for years, even in humid environments.

Note: Always check the weight rating of the strap before using it for heavy pipes or large ducts.

Electrical Applications

Cable Management

You organize and secure cables with galvanized steel straps in electrical installations. The strap bundles wires together and keeps them off the ground. You reduce clutter and prevent damage to cables. The strap works well in both residential and commercial settings. You can use it to fasten cables to walls, ceilings, or support beams.

Alert: Use perforated straps for easy installation when managing multiple cables.

Packaging and Shipping

Galvanized steel straps play a key role in packaging and shipping. You need strong, reliable materials to keep heavy items secure during transport. These straps give you the strength and corrosion resistance you need for demanding shipping environments.

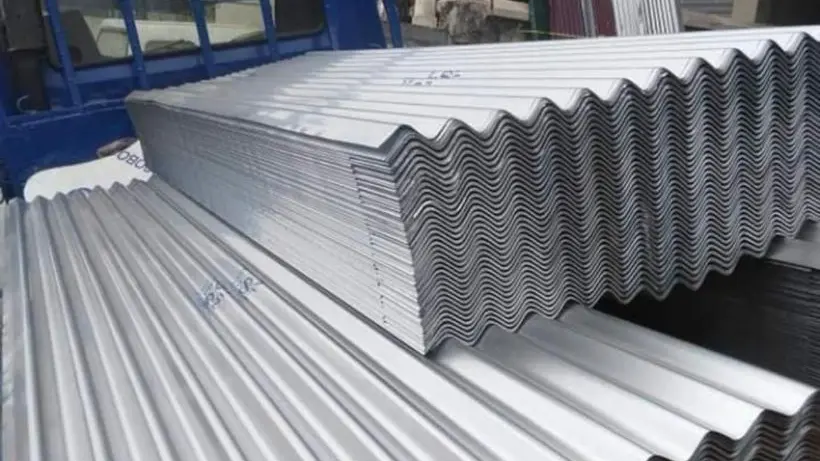

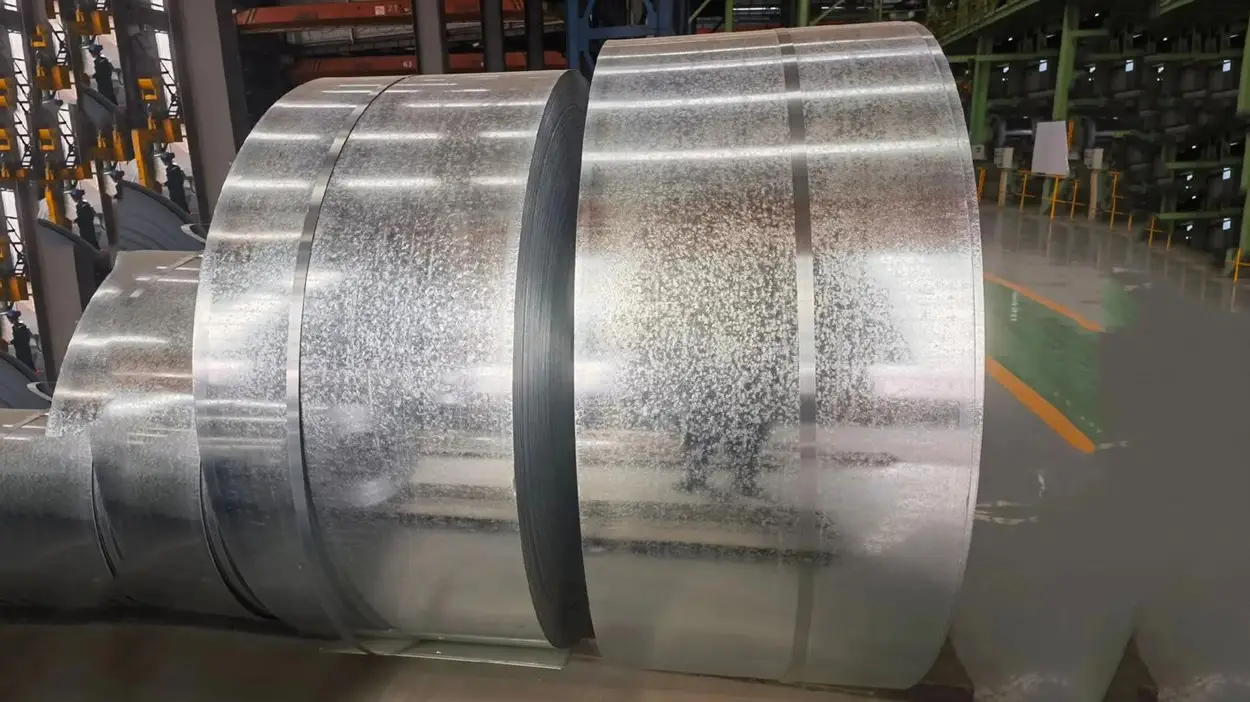

Bundling Steel Coils

You often use galvanized steel straps to bundle steel coils. Steel coils are heavy and can shift during shipping. When you wrap a galvanized strap around the coil, you keep it tightly bound. The zinc coating protects the strap from moisture, so you do not have to worry about rust, even if the coils sit outside or travel long distances.

Tip: Always check the tension of the strap before shipping. A tight strap prevents movement and reduces the risk of damage.

Securing Metal Bundles

You can secure bundles of metal rods, pipes, or sheets with galvanized steel straps. These bundles often weigh hundreds or thousands of pounds. The strap holds everything together, so nothing shifts or falls apart during loading, unloading, or transit. You get peace of mind knowing your materials will arrive safely.

- Use solid straps for the heaviest bundles.

- Choose perforated straps if you need to adjust the fit or use fasteners.

Binding Pavers and Bricks

You also use galvanized steel straps to bind pavers, bricks, and other masonry products. These materials can break or scatter if not properly secured. The strap wraps tightly around the stack, holding everything in place. The zinc coating keeps the strap strong, even if the shipment faces rain or humidity.

| Application | Why Use Galvanized Steel Strap? | Key Benefit |

|---|---|---|

| Steel Coils | Prevents shifting and rust | Safe, corrosion-free load |

| Metal Bundles | Holds heavy items together | Reliable transport |

| Pavers & Bricks | Secures fragile, heavy materials | Reduces breakage |

Alert: Always use the correct strap width and thickness for your load. Too thin, and the strap may snap. Too wide, and it may not fit your packaging equipment.

Outdoor Projects

You can rely on galvanized steel straps for many outdoor projects. The zinc coating stands up to rain, snow, and sun, so you get long-lasting performance.

- Fencing: Use straps to attach fencing panels to posts. The strap resists rust, so your fence stays strong year after year.

- Garden Structures: Secure trellises, arbors, or raised beds with galvanized straps. You get sturdy support for plants and garden features.

- Decks and Sheds: Reinforce joints and fasten beams with these straps. The corrosion resistance keeps your outdoor structures safe and stable.

- Playground Equipment: Fasten swings, slides, or climbing frames with galvanized straps. You protect the steel from weather and ensure safety for children.

Note: Galvanized steel straps work well in coastal areas, where salty air can quickly rust other metals. You get extra protection and longer life for your outdoor projects.

When you choose galvanized steel straps for packaging, shipping, or outdoor projects, you invest in safety, durability, and peace of mind. You keep your materials secure and your structures strong, no matter the environment.

Benefits of Galvanized Steel Strap

Durability

You want a fastening solution that stands up to daily wear and tear. Galvanized steel straps give you impressive durability. The steel core provides solid strength, while the zinc coating shields the strap from scratches and impacts. You can use these straps in places where heavy loads and constant movement are common. The strap does not crack or split easily, so you avoid frequent replacements. You get a product that lasts for years, even in tough environments.

Tip: Choose galvanized steel straps for projects that require long-term reliability. You save time and money by reducing maintenance and replacement needs.

Rust Resistance

You often face moisture, humidity, or exposure to the elements in your projects. Rust can weaken ordinary steel and cause failures. Galvanized steel straps solve this problem with their zinc coating. The zinc acts as a barrier, stopping water and air from reaching the steel. You can use these straps outdoors, in basements, or near plumbing without worrying about corrosion. The rust resistance keeps your installations safe and secure.

A galvanized steel strap works well in coastal areas, gardens, and construction sites. You do not need to worry about rain or snow damaging your fasteners. The strap keeps its shape and strength, so your materials stay in place.

| Feature | Benefit |

|---|---|

| Zinc Coating | Prevents rust and corrosion |

| Steel Core | Maintains strength over time |

| Long Service Life | Reduces replacement frequency |

Note: Rust resistance is especially important for outdoor projects and areas with high humidity.

Load Capacity

You need to know how much weight your strap can handle. Galvanized steel straps offer impressive load capacity, making them suitable for heavy-duty tasks. The strength depends on the size and thickness of the strap. For example:

- A 1-1/2″ x 16 gauge strap supports up to 150 lbs.

- A 2″ x 12 gauge strap may support over 700 lbs.

You can trust these straps to hold beams, pipes, and bundles securely. Galvanized steel is stronger and tougher than copper or plastic alternatives. You get better performance for demanding jobs. The strap also offers better corrosion resistance than plain steel and costs less than stainless steel.

Alert: Always check the specifications before choosing a strap for your project. Using the right size ensures safety and stability.

You get peace of mind knowing your materials are secure. The high load capacity means you can use galvanized steel straps for construction, shipping, and outdoor installations without worry.

Cost-Effectiveness

You want to get the most value for your money when you choose materials for your project. Galvanized steel straps help you save costs in several ways. The initial price is lower than many alternatives, such as stainless steel or specialty metals. You do not need to pay a premium for reliable strength and corrosion resistance.

You also save money over time. The zinc coating protects the steel from rust, so you avoid frequent replacements. You do not need to spend extra on maintenance or repairs. The long service life means you can use these straps for years without worrying about sudden failures.

Consider the following cost-saving benefits:

- Lower Purchase Price: Galvanized steel straps cost less than stainless steel, copper, or aluminum straps. You can buy more for your budget.

- Reduced Maintenance: The zinc coating prevents rust, so you do not need to treat or replace straps often.

- Long-Term Durability: You avoid the expense of frequent replacements. The straps stay strong and reliable for many years.

- Versatile Use: You can use one type of strap for many applications. This flexibility reduces the need to buy different products.

Tip: If you work on large projects, buying galvanized steel straps in bulk can lower your costs even more. Suppliers often offer discounts for bigger orders.

Here is a simple comparison to help you see the savings:

| Strap Type | Initial Cost | Maintenance Needs | Expected Lifespan | Overall Value |

|---|---|---|---|---|

| Galvanized Steel | Low | Minimal | Long | High |

| Stainless Steel | High | Minimal | Long | Moderate |

| Plastic | Low | Moderate | Short | Low |

| Aluminum | Moderate | Moderate | Moderate | Moderate |

You can see that galvanized steel straps offer a strong balance between price and performance. You do not sacrifice quality for savings. The straps work well in construction, plumbing, packaging, and outdoor projects. You get reliable results without overspending.

You also benefit from easy installation. The straps are lightweight and flexible, so you do not need special tools or extra labor. You finish your project faster and reduce labor costs.

Note: Always check the specifications before you buy. Choosing the right size and type helps you avoid waste and maximize your savings.

Galvanized steel straps give you a cost-effective solution for many jobs. You protect your budget while ensuring safety and durability. You make a smart choice for both small repairs and large construction projects.

Alternatives Comparison

When you choose a strap for your project, you may wonder about other options besides galvanized steel. You can compare stainless steel, plastic, and aluminum straps. Each type offers unique benefits and drawbacks. Understanding these alternatives helps you make the best decision for your needs.

Stainless Steel Straps

Stainless steel straps give you excellent corrosion resistance. You can use them in environments with high moisture, chemicals, or salt. These straps do not rust easily. You get a clean, shiny finish that looks professional. Stainless steel straps handle heavy loads and high tension.

Advantages:

- High strength and durability

- Superior rust resistance

- Attractive appearance

Disadvantages:

- Higher cost than galvanized steel

- Heavier weight

- May require special tools for installation

Tip: Choose stainless steel straps for marine projects or chemical plants. You get maximum protection against corrosion.

| Feature | Stainless Steel Strap |

|---|---|

| Corrosion Resistance | Excellent |

| Cost | High |

| Weight | Heavy |

| Load Capacity | High |

Plastic Straps

Plastic straps offer a lightweight and flexible solution. You can use them for bundling, packaging, or light-duty tasks. These straps resist moisture and do not conduct electricity. You get easy installation with simple tools.

Advantages:

- Lightweight and easy to handle

- No risk of rust

- Safe for electrical applications

Disadvantages:

- Lower strength than metal straps

- Can break under heavy loads

- Limited durability in extreme temperatures

Alert: Use plastic straps for light packages or temporary fixes. Avoid them for structural support or outdoor projects.

| Feature | Plastic Strap |

|---|---|

| Corrosion Resistance | Good |

| Cost | Low |

| Weight | Very Light |

| Load Capacity | Low |

Aluminum Straps

Aluminum straps give you a balance between strength and weight. You can use them for medium-duty tasks. These straps resist rust and corrosion. You get a strap that is easy to cut and shape.

Advantages:

- Lightweight but strong

- Good corrosion resistance

- Easy to work with

Disadvantages:

- Not as strong as steel

- Can bend or deform under high tension

- More expensive than plastic

Note: Choose aluminum straps for projects where weight matters and moderate strength is enough.

| Feature | Aluminum Strap |

|---|---|

| Corrosion Resistance | Good |

| Cost | Moderate |

| Weight | Light |

| Load Capacity | Medium |

Summary Table:

| Strap Type | Strength | Corrosion Resistance | Cost | Weight | Best Use Case |

|---|---|---|---|---|---|

| Galvanized Steel | High | Very Good | Low | Medium | Construction, outdoor, heavy |

| Stainless Steel | High | Excellent | High | Heavy | Marine, chemical, industrial |

| Plastic | Low | Good | Low | Very Light | Packaging, light-duty |

| Aluminum | Medium | Good | Moderate | Light | Medium-duty, weight-sensitive |

You can see that each strap type fits different needs. You should consider your project requirements before you choose. Galvanized steel straps give you a strong, cost-effective option for most jobs. Stainless steel, plastic, and aluminum straps offer solutions for special situations.

Industry Applications

Residential

You often use galvanized steel straps in residential settings for safety and support. When you build a house, you need to secure framing, attach joists, and reinforce beams. These straps help you keep walls and ceilings stable. You can also use them to hang pipes in basements or support ductwork in attics. If you install fences or garden structures, you rely on these straps to hold everything together, even in wet or humid conditions. Homeowners choose them because they resist rust and last for years.

Tip: Use a galvanized steel strap for outdoor projects like decks or sheds. You get extra protection against rain and snow.

Common residential uses:

- Fastening wood framing

- Hanging plumbing pipes

- Supporting HVAC ducts

- Securing fences and garden features

Commercial

You see galvanized steel straps in many commercial buildings. Contractors use them to reinforce large frameworks, secure heavy pipes, and attach electrical conduits. In offices, schools, and retail spaces, these straps help you organize cables and support suspended ceilings. You can also use them for mounting signs or securing equipment. The straps handle high traffic and frequent use, so you do not worry about sudden failures.

A table can help you see where you might use these straps in commercial settings:

| Application | Benefit |

|---|---|

| Framework support | Increases building stability |

| Pipe and duct hanging | Prevents sagging and leaks |

| Cable management | Reduces clutter and hazards |

| Equipment mounting | Ensures secure installation |

Note: Always check the weight rating before using straps for heavy commercial equipment.

Industrial

You depend on galvanized steel straps in industrial environments for their strength and reliability. Factories, warehouses, and plants use these straps to bundle steel coils, secure pallets, and fasten machinery. You can also use them to reinforce storage racks or attach safety barriers. The zinc coating protects the straps from chemicals, moisture, and extreme temperatures. This makes them ideal for harsh conditions where other materials might fail.

Key industrial applications:

- Bundling heavy materials for shipping

- Securing machinery and equipment

- Reinforcing storage systems

- Attaching safety guards and barriers

Alert: In industrial settings, always inspect straps regularly. Replace any that show signs of wear to maintain safety.

You can see that a galvanized steel strap fits many roles across different industries. You get a versatile tool that supports construction, plumbing, HVAC, and packaging needs. This flexibility makes it an essential part of your toolkit, whether you work at home, in a business, or in a factory.

You now know that a galvanized steel strap gives you strong, rust-resistant support for many jobs. You can use it in HVAC for ductwork, in electrical work for wire routing, in construction for structural support, and in plumbing for long-lasting pipe runs. This strap offers durability, cost savings, and easy installation. Think about your project needs and choose a galvanized steel strap to get reliable results every time.

- HVAC: Supports ductwork, piping, and equipment

- Electrical: Routes wire and conduit, resists corrosion

- Construction: Supports temporary and structural parts

- Plumbing: Lasts long and resists rust for pipes

FAQ

What is the main advantage of using a galvanized steel strap?

You get strong, long-lasting support with excellent rust resistance. The zinc coating protects the steel, so you can use it in wet or outdoor environments without worrying about corrosion.

Can you cut galvanized steel straps to size?

Yes, you can cut galvanized steel straps with tin snips or a metal cutting tool. Always wear gloves and safety glasses to protect yourself from sharp edges.

Where should you avoid using galvanized steel straps?

You should avoid using galvanized steel straps in environments with strong acids or chemicals. These substances can damage the zinc coating and reduce the strap’s lifespan.

How do you install a galvanized steel strap?

You wrap the strap around the object, then secure it with screws, bolts, or nails. For best results, use the correct fasteners for your material and check the tension.

Are galvanized steel straps safe for electrical work?

Yes, you can use galvanized steel straps for cable management and conduit support. The zinc coating prevents rust, but the strap still conducts electricity. Avoid direct contact with live wires.

How do you store galvanized steel straps?

Store galvanized steel straps in a dry place. Keep them off the ground and away from chemicals. This helps prevent damage and keeps the straps ready for your next project.

What sizes do galvanized steel straps come in?

You can find galvanized steel straps in many widths, thicknesses, and lengths. Common widths range from 1/2 inch to 2 inches. Always check the product label for exact measurements.

Can you paint over galvanized steel straps?

Yes, you can paint over galvanized steel straps. Clean the surface first and use a primer made for galvanized metal. This helps the paint stick and protects the strap.