Introduction

In the world of construction, automotive manufacturing, roofing, and fabrication, galvanized steel sheets and galvannealed steel sheets are some of the most trusted and widely used materials. These coated steel products provide excellent corrosion resistance, durability, and aesthetic appeal, making them a staple in both industrial and domestic applications.

In this blog post, we’ll dive into the different types of galvanized steel products, compare galvanized sheet metal prices, explain their applications, and explore current trends in the market.

What is Galvanized Steel Sheet?

Galvanized steel sheet is a cold-rolled steel sheet that has been coated with a layer of zinc to protect it from corrosion. The zinc coating serves as a barrier to environmental elements and also sacrifices itself to protect the steel if the surface becomes scratched.

There are two main methods of galvanization:

Among these, hot dip galvanized steel sheet is the most popular due to its thicker coating and superior corrosion resistance.

What is Galvannealed Steel Sheet?

A galvannealed steel sheet is produced by combining the processes of galvanizing and annealing. After the steel is hot-dip galvanized, it is heated in an annealing furnace. This causes the zinc to bond with the steel at a molecular level, forming a zinc-iron alloy layer.

This process gives the steel a matte finish, which is ideal for painting and welding. Galvannealed steel sheets are widely used in automotive panels, appliances, and building facades.

Types of Galvanized Steel Products

The variety of galvanized products available today allows engineers and manufacturers to choose materials based on their specific needs. Below are some commonly available forms:

A. Galvanized Plain Sheet

The galvanized plain sheet has a smooth finish and is widely used in ducting, wall cladding, and fencing. These sheets are available in various thicknesses and sizes.

B. Galvanized Zinc Sheet

This term is often used interchangeably with galvanized steel sheets. A galvanized zinc sheet simply means the sheet has been coated with zinc, providing the same corrosion resistance and durability.

C. Galvanised Flat Sheets

Galvanised flat sheets are cut-to-size galvanized sheets, typically used in construction, interior design, and ventilation systems. These sheets offer flexibility for custom fabrication.

Pre Painted Galvalume Sheet

The pre painted galvalume sheet is a coated product made from aluminum-zinc alloy and painted with high-performance coatings. These sheets offer superior resistance to corrosion and heat, making them ideal for roofing and siding in coastal and high-temperature areas.

Applications of Galvanized and Galvannealed Steel Sheets

The demand for galvanized steel sheets and galvannealed steel sheets stems from their versatile applications across industries:

- Construction: Roofs, gutters, wall cladding, structural framing, and ductwork.

- Automotive: Car body panels, underbody shields, and reinforcement parts.

- Agriculture: Storage bins, silos, fencing, and livestock enclosures.

- HVAC systems: Air ducts and housings.

- Furniture and appliances: Refrigerators, washing machines, office furniture.

- The matte surface of galvannealed steel sheet is especially valued in sectors where paintability and weldability are critical.

Galvanized Steel Sheet Price Trends

Understanding galvanized sheet metal prices is crucial for contractors, project managers, and procurement teams. Prices vary depending on:

- Thickness and size

- Zinc coating weight

- Market demand and supply

- Steel grade and finish

- Geographic location

Factors Affecting Galvanized Sheet Metal Prices

Several key factors influence galvanized metal sheet and galvanized metal sheets pricing:

- Raw Material Costs: Fluctuations in steel and zinc prices affect the base cost.

- Energy and Transportation: Shipping and processing costs add to the final price.

- Import Tariffs and Trade Policies: Duties and tariffs can make imported sheets more expensive.

- Market Demand: Peak construction seasons can spike prices.

- Sheet Coating Weight: G90-coated sheets cost more than G30 due to thicker zinc layers.

- Processing and Finish: Pre-painted, embossed, or corrugated finishes increase cost.

How to Choose the Right Galvanized Steel Product

When selecting a steel sheet for your application, consider the following:

1. Environmental Exposure

For coastal or high-humidity areas, opt for pre painted galvalume sheet or hot dip galvanized steel sheet for maximum corrosion resistance.

2. Painting Requirement

Use galvannealed steel sheet for surfaces that require post-fabrication painting.

3. Structural Strength

For structural components, select sheets with higher tensile strength and thicker gauge.

4. Budget

Balance between protection and price. Standard galvanised sheet metal prices are generally more economical for non-critical applications.

Sustainability and Recycling of Galvanized steel

Galvanized steel is highly recyclable. At the end of its life, it can be melted down and reused in new steel products. The zinc coating, though lost during remelting, does not pose any environmental threat.

Manufacturers today are increasingly adopting sustainable practices such as:

- Using recycled steel

- Reducing emissions during galvanizing

- Offering take-back programs

Final Thoughts

Whether you’re sourcing galvanized zinc sheet, galvanized plain sheet, or pre painted galvalume sheet, understanding the types, applications, and price factors is essential for making informed procurement decisions.

The popularity of galvanised flat sheets and hot dip galvanized steel sheet continues to grow, especially in fast-paced industries like construction and automotive manufacturing. As global infrastructure demand rises, keeping an eye on galvanized steel sheet price trends will help businesses stay competitive and cost-efficient.

Qingdao Witop Steel group are a first-class iron and steel enterprise in China. The group mainly produce cold rolled steel, hot dipped galvanized steel, hot dipped galvalume steel, pre-painted/color coated steel, tinplate, color stone coated roof tile and other steel materials. Our Sales team is always at your service to find your best steel materials according to need.

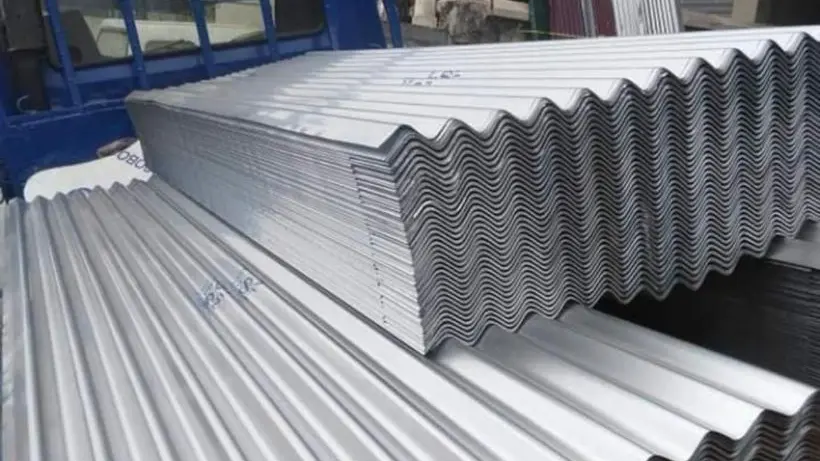

When galvanized roofing sheets comes to durable, cost-effective, and long-lasting roofing solutions, sheet metal for roofing is a popular choice among homeowners, builders, and contractors. Among the various options available, galvanized roofing sheets stand out due to many reasons.

Galvanized sheets are highly resistant to rust and corrosion, making them ideal for roofs in areas with high humidity or exposure to harsh weather conditions.

Galvanized Roofing Sheets are one of the leading products of Witop Steel group. Focusing on “stabilizing high quality and establishing brand”, Witop Steel has established a stable raw material supply and sales network in more than 100 countries and 180 customers, and enjoys a high reputation in the domestic and foreign markets.

In this guide, we will explore different types of galvanized roofing sheets, their pricing, benefits, and installation methods.