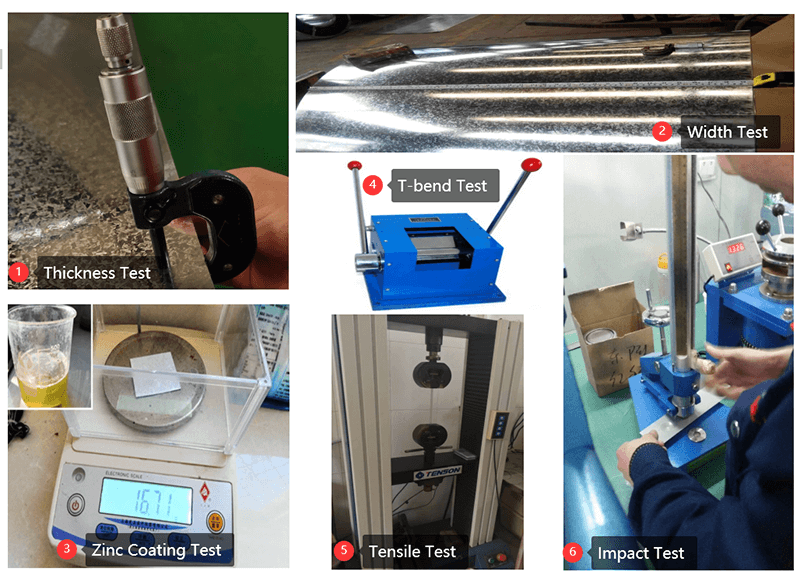

Quality Control and Self-inspection

WITOP steel have the advanced testing equipment and professional team. WITOP steel strictly control the quality on each step of production, including inspection on raw materials, product’s thickness and width test, zinc coating test, T-bend test, impact test, tensile test, salt-spray test and package testing on exporting steel coil, which ensures its integrated performance and quality.

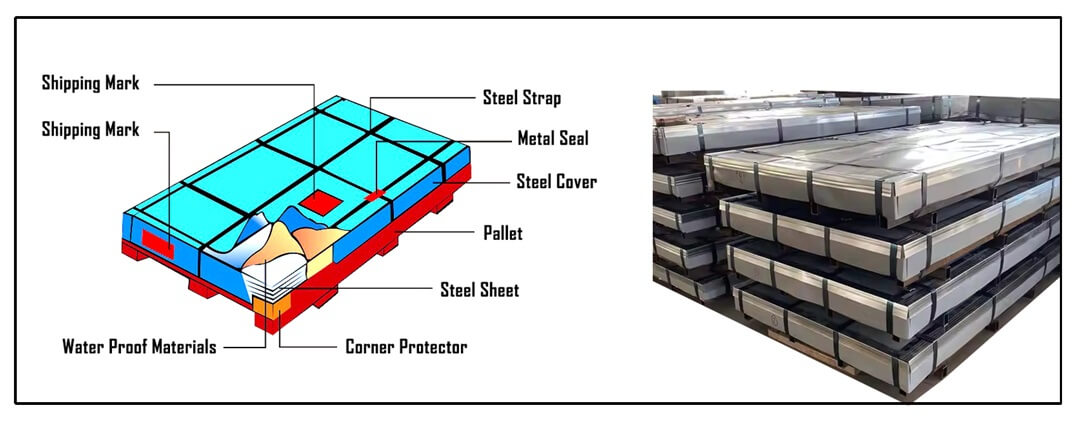

Product Package

Standard export package: 3 layers of packing, inner side is anti-water craft paper, PVC plastic film is the middle and outer side covered by at least 0.45mm thick steel sheet,wrapped by minimum seven steel strapping strips with lock catch.

In particular, WITOP steel places desiccant on the coil inner core side and on both lateral sides of the coil for bulk transportation to ensure that coils are delivered to clients in good condition.

Package can be customized as client’s requirements.

Loading and Fastening Galvanized Steel Sheet

WITOP steel have our own loading and fastening workers and team, which can fasten steel coils and sheet well in container and bulk based on ship line company. WITOP steel can guarantee galvanized steel coil well to every client.

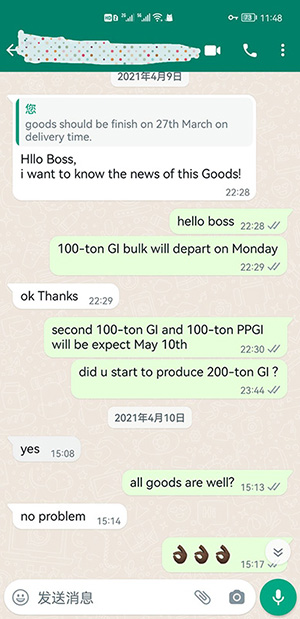

Main Market and Customer’s Feedback

WITOP steel have exported galvanized steel coil to Ethiopia, Somalia, Kenya, Tanzania, South Africa, Nigeria, Guinea, Ghana, Saudi Arabia, UAE, Kuwait, Iraq, Yemen, Singapore, Indonesia, Philippines, Thailand, Chile, Peru, Argentina, Bolivia and other countries for twenty years. Hot dipped galvanized steel coil have gained good reputation and wide appreciation throughout Africa, Middle East, Middle Asia, Southeast Asia and South America.