Introduction

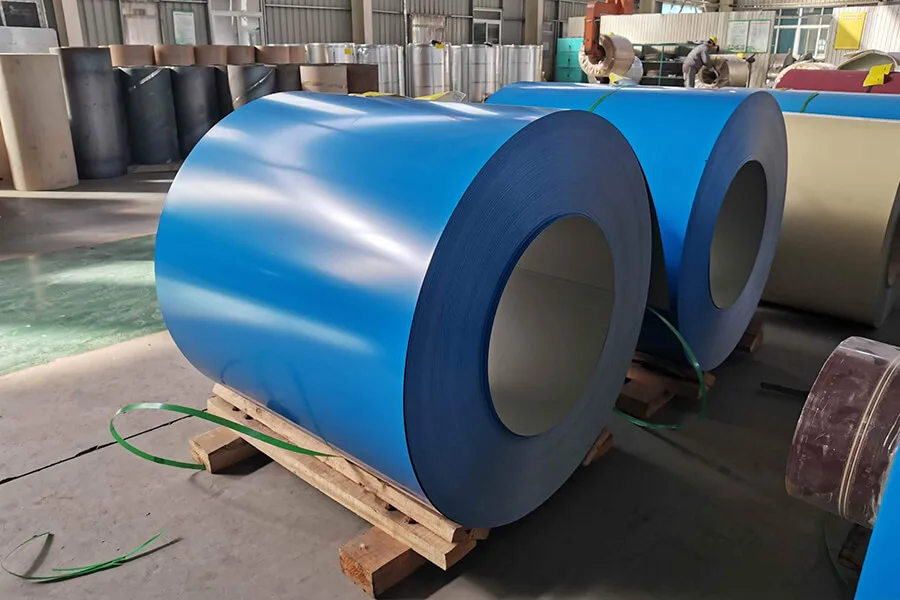

Let’s look around us Steel coil! The car we drive, the appliances in our kitchen, the building we work in, and the shelves in our local supermarket. Many of these structures and products began their life not as finished goods, but as solid, tightly wound rolls of metal known as steel coils. This versatile and economical form factor is the key building block for countless industries worldwide.

This guide will take you on a deep dive into the world of steel coils. We’ll unravel the manufacturing processes, compare the distinct properties of each type, and explore their vast applications. Furthermore, with the global market increasingly looking towards China steel coil for its competitive balance of quality and cost, we will also provide key insights for sourcing these essential materials effectively.

The Groundwork: Understanding Steel Coils

At its core, a steel coil is a continuous length of steel that has been rolled into a spiral. This process of coiling allows for efficient storage, transportation, and subsequent processing of large quantities of steel. The journey from molten metal to a finished coil involves sophisticated metallurgical processes and extensive rolling operations.

The initial rolling process can be broadly categorized into two main types: hot rolling and cold rolling.

- Hot Rolling: Steel is heated to high temperatures (above re crystallization temperature) and then passed through rollers. This process is relatively economical and produces steel with good formability. However, it results in a less precise finish and can lead to some dimensional inaccuracies.

- Cold Rolling: This process is performed at or near room temperature, after the steel has been hot-rolled and cooled. Cold rolling further reduces the thickness, improves surface finish, and enhances mechanical properties like strength and hardness. This is where the distinction of cold rolled steel coil becomes significant.

Cold Rolled Steel Coil: Precision and Superior Finish

A cold rolled steel coil undergoes a series of additional rolling passes at room temperature after hot rolling. This meticulous process refines the material’s micro-structure, resulting in several key advantages:

- Superior Surface Finish

- Tighter Tolerances

- Enhanced Mechanical Properties

Applications of Cold Rolled Steel Coil

- Automotive: Body panels, chassis components, and interior parts benefit from the strength and smooth finish of cold-rolled steel.

- Appliances: The sleek exteriors of refrigerators, washing machines, and ovens often utilize cold-rolled steel for its aesthetic appeal and durability.

- Furniture: Office furniture, shelving units, and other metal furniture pieces frequently employ cold-rolled steel.

- Electrical Equipment: Enclosures for electrical panels, transformers, and electronic devices require the dimensional accuracy and surface quality of cold-rolled steel.

- General Manufacturing: Numerous general engineering applications, where precise dimensions and a good finish are paramount, rely on cold-rolled steel.

Coated Steel Coil: Adding Protection and Functionality

While steel is strong, it is susceptible to corrosion. To enhance its durability and expand its application range, various coatings are applied to steel coils. This leads us to the broad category of coated steel coil. These coatings serve multiple purposes, from preventing rust to providing decorative finishes.

The process of coating can occur at different stages and involves various materials. Key types of coated steel coils include:

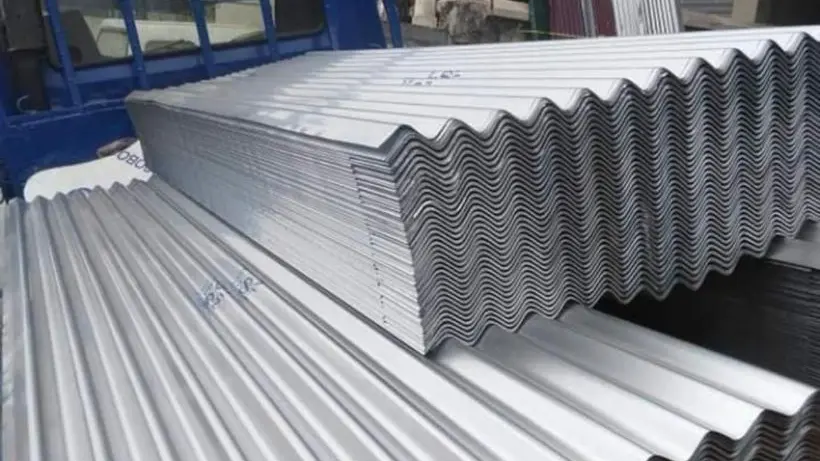

Galvanized Steel Coil: The Rust-Resistant Champion

Galvanized steel coil is perhaps the most widely recognized type of coated steel. It is produced by passing a steel coil through a bath of molten zinc (hot-dip galvanizing) or through an electrolytic process. This zinc coating provides a sacrificial layer of protection. Even if the coating is scratched, the zinc will corrode preferentially, protecting the underlying steel from rust.

Galvanized Steel Sheet Coil:

A galvanized steel sheet coil is essentially a galvanized steel coil that has been further processed or is intended for applications where it will be used in sheet form. The term often refers to the material’s form factor and its primary protective coating.

Applications of Galvanized Steel Coil:

The exceptional corrosion resistance of galvanized steel makes it ideal for:

- Construction: Roofing, siding, structural components, gutters, and downspouts.

- Automotive: Vehicle underbodies, exhaust systems, and structural elements.

- Appliances: Washing machine drums, refrigerator liners, and appliance housings.

- Agriculture: Fencing, silos, and farm equipment.

- General Industry: Water tanks, ductwork, and metal furniture.

Pre-Painted Steel Coil: Aesthetics and Protection in One

Pre-Painted steel coil, also known as pre-painted steel coil or coil coating, involves applying a layer of paint or organic coating to a steel substrate (often cold-rolled or galvanized steel) in a continuous process. This offers both corrosion protection and a decorative finish in a single product.

Color Coated Steel Coil: A Spectrum of Possibilities

Color coated steel coil is a specialized form of painted steel coil where the primary focus is on providing a wide range of colors and finishes for aesthetic appeal. This category often encompasses advanced coatings that offer enhanced performance characteristics alongside their vibrant hues.

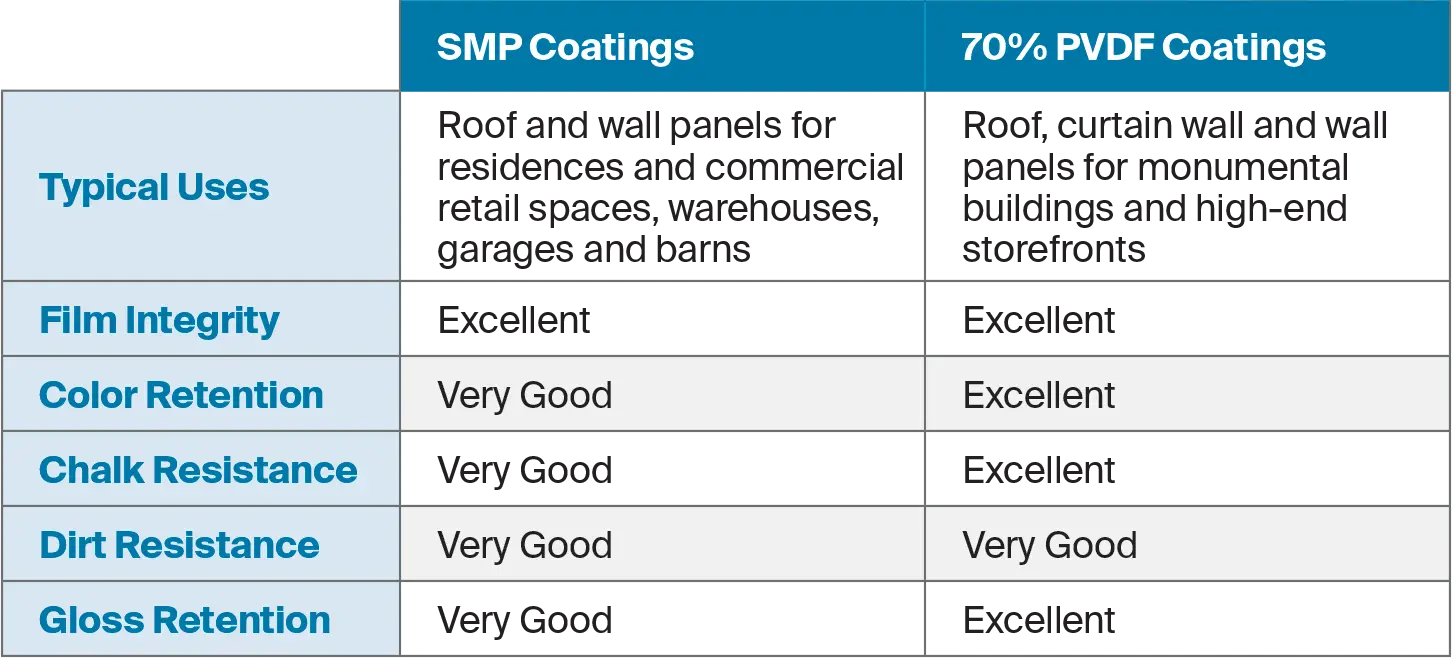

Types of Paints/Coatings for Color Coated Steel Coil:

- Polyester (PE): A versatile and cost-effective coating, suitable for general applications where moderate durability and flexibility are required.

- Silicon Modified Polyester (SMP): Offers improved hardness, gloss retention, and chalk resistance compared to standard polyester.

- Polyvinylidene Fluoride (PVDF): Known for its exceptional UV resistance, color stability, and resistance to chalking and fading, making it ideal for exterior applications in harsh environments.

- Plastisol: A thicker coating that provides excellent corrosion resistance, good flexibility, and a textured finish.

Applications of Painted and Color Coated Steel Coil

- Building Facades and Roofing: The vibrant colors and durable finishes are perfect for architectural cladding, roofing panels, and decorative elements.

- Appliances: The smooth, colorful finishes enhance the appeal of refrigerators, ovens, washing machines, and other home appliances.

- Interior Design: Wall panels, ceilings, and decorative features in commercial and residential spaces.

- Automotive: Interior trim, decorative elements, and some exterior components.

- Signage and Displays: Eye-catching and weather-resistant materials for outdoor and indoor signage.

China Steel Coil: A Global Powerhouse

China steel coil represents a significant portion of the global steel coil market. China has emerged as the world’s largest producer and exporter of steel, and this includes a vast range of steel coils. The country’s massive industrial capacity, coupled with continuous investment in technology and infrastructure, allows it to produce steel coils at competitive prices and in a wide variety of specifications.

Key Aspects of China Steel Coil:

- Scale of Production: China’s steel production dwarfs that of other nations, ensuring a consistent and abundant supply of various steel coil types.

- Technological Advancements: Chinese steel manufacturers have invested heavily in modern rolling mills, coating lines, and quality control systems, enabling them to produce high-quality products that meet international standards.

- Diverse Product Range: From basic hot-rolled coils to sophisticated color coated steel coil and high-strength cold rolled steel coil, Chinese manufacturers offer a comprehensive portfolio.

- Cost-Effectiveness: Economies of scale and efficient production processes often translate into competitive pricing for China steel coil, making it an attractive option for global buyers.

- Export Hub: China is a primary source for steel coils for industries worldwide, serving as a crucial link in global supply chains.

Considerations when sourcing China Steel Coil

While the benefits are clear, it’s important for international buyers to consider:

- Quality Standards: Ensuring the chosen supplier adheres to relevant international quality certifications (e.g., ISO, ASTM, EN).

- Specifications: Clearly defining the required steel grade, dimensions, coating type, and performance characteristics.

- Logistics and Shipping: Understanding shipping costs, lead times, and potential import duties.

- Supplier Reputation: Researching and verifying the reliability and track record of the manufacturer.

The Interplay of Different Steel Coil Types

It’s important to recognize that these categories are not mutually exclusive. For example:

- A color coated steel coil is also a type of coated steel coil and is often based on a galvanized steel coil or cold rolled steel coil substrate.

- A painted steel coil might be produced from a cold rolled steel coil for applications demanding a superior surface finish.

- When referring to China steel coil, one could be talking about any of the aforementioned types – galvanized steel coil, cold rolled steel coil, color coated steel coil, etc., manufactured in China.

Conclusion

The world of steel coils is huge and intricate, a testament to human ingenuity in transforming a fundamental metal into a material of incredible utility. From the precision of cold rolled steel coil to the robust protection of galvanized steel coil, and the aesthetic versatility of painted steel coil and color coated steel coil, each type plays a crucial role in shaping our modern infrastructure and consumer goods.

Understanding the nuances of these different steel coil types is essential for anyone involved in manufacturing, construction, or design, enabling informed choices that lead to stronger, more durable, and more aesthetically pleasing end products. The ongoing evolution of steel coil technology promises even more exciting developments, ensuring its continued relevance and importance in the decades to come.

Qingdao Witop Steel group are a first-class iron and steel enterprise in China. Through a highly efficient technological and industrial base in China and a global commercial network, we are committed to establishing a long-term cooperation with the customers.