Hot Dip Alu-Zn-Mg Alloy Coated Steel

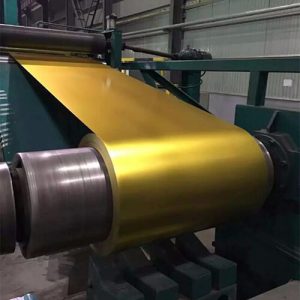

Hot Dip Alu-Zn-Mg Alloy Coated Stee is a new type of highly corrosion-resistant metallic coated steel plate. The Alu-Zn-Mg composition includes 5-57% aluminum, 43-86% zinc, 2-3% magnesium. 1.5% silicon and other elements.The thickness range that can be produced is 0.27mm—9.00mm, and the width range that can be produced is: 580mm—1250mm.

Compared with traditional hot-dip galvanizing, Hot Dip Alu-Zn-Mg Alloy Coated Stee has significantly improved plane corrosion resistance and notch corrosion resistance. It is widely used in the construction and electrical appliance industries and helps to greatly increase the service life of steel plates.

Product Classification

Hot Dip Alu-Zn-Mg Alloy Coated Steel can be categorized based on the aluminum content in the coating:

- Low Aluminum (Al < 5%): Examples include Thyssen’s ZM Ecoprotect®, Voestalpine’s Corrender®, Tata Europe’s MagiZinc®, and others. These are commonly used for automotive applications due to their good formability and corrosion resistance.

- Medium Aluminum (5-13%): This category includes products like Nisshin Steel’s ZAM® and Nippon Steel’s SuperDyma®. These coatings offer balanced performance characteristics, making them suitable for a wide range of applications.

- High Aluminum (47-57%): For instance, BlueScope’s next-generation ZINCALUME® falls into this category, offering exceptional corrosion resistance, particularly in harsh environments.

Corrosion Resistance

The corrosion resistance of Alu-Zn-Mg coatings is superior to traditional zinc coatings. The International Zinc Association has conducted extensive research, demonstrating that increased Al and Mg content enhances the material’s corrosion resistance. However, the rate of improvement decreases once the combined Al and Mg content exceeds 5%. Among the best-performing materials in corrosion resistance are Galvalume® (Al-Zn), ZAM®, and SuperDyma® .

| Company Name | Products | Alu(%) | Mg(%) | Zinc and Other(%) |

| NSSMC | SuperZinc | 4.5 | 0.1 | 95.4 |

| DymaZinc | 0.2 | 0.5 | 99.3 | |

| SuperDyma | 11 | 3 | 86 | |

| NISSHIN | ZAM | 6 | 3 | 91 |

| THYSSENKRUPP | ZM ECOPROTECT | 1 | 1 | 98 |

| VOESTALPINE | CORRENDER | 2.5 | 1.5 | 96 |

| TATA STEEL | MAGIZINC | 1.6 | 1.6 | 96.8 |

| JFE | ECOGAL | 5 | 0.8 | 94.2 |

| WUPPERMANN | WZM | 2 | 2 | 96 |

| SALZHITTER | STRONSAL | 1.0-2.0 | 1.0-2.0 | 96-98 |

| ArcelorMittal | MAGNELIS | 3.5 | 3 | 93.5 |

| POSCO | PosMAC | 2.5 | 3 | 94.5 |

| BlueScope | Zincalume | 55 | 2 | 43 |

| Witop Steel | AZM | 11 | 2 | 87 |

In comparison, Alu-Zn-Mg coatings with low aluminum content show corrosion resistance comparable to Galfan® (Zn-Al), significantly outperforming pure zinc coatings. European steelmakers have evaluated the use of low aluminum Alu-Zn-Mg coatings in automotive panels, concluding that these coatings offer better formability and corrosion resistance, making them interchangeable among different manufacturers.

Features

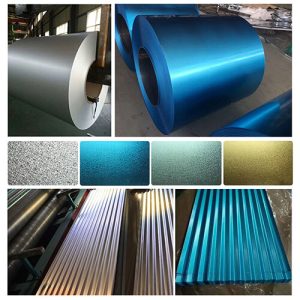

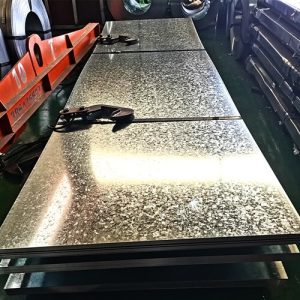

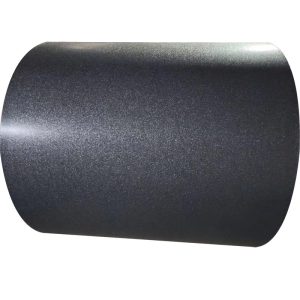

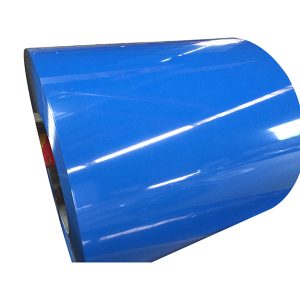

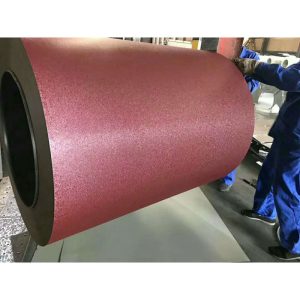

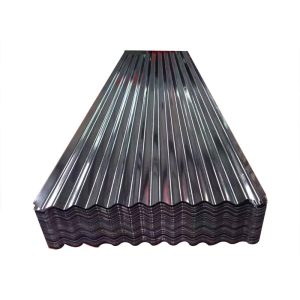

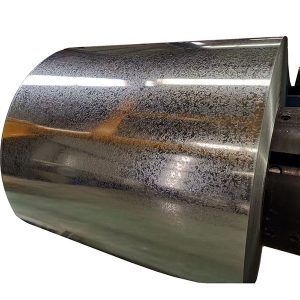

Appearance: The surface of Alu-Zn-Mg coated steel has a fine crystalline zinc flower pattern, giving it a natural and refined appearance. A special resin film can be applied for added protection and to maintain the metal’s shine. The zinc flowers are finer and more uniform compared to traditional Al-Zn coatings .

Properties: The Alu-Zn-Mg coating provides excellent corrosion resistance. The synergy among zinc, aluminum, and magnesium slows the consumption of the coating and enhances the cut-edge protection. This is crucial in preventing corrosion at the exposed edges, which is a common issue in other types of coated steels. Typically, the service life of Alu-Zn-Mg coated steel exceeds 30 years under normal environmental conditions.

Corrosion Mechanism: The Alu-Zn-Mg alloy coating works by providing sacrificial protection through zinc, passive protection through aluminum, and activation protection through magnesium. The magnesium activates the alloy coating, enhancing the barrier protection at cuts and edges, significantly improving overall corrosion resistanc.

Coating Weight and Economics

The coating weight for Alu-Zn-Mg ranges from 100g/m² to 180g/m², with common specifications like AZM150 and AZM100. Due to the lower density of the Al-Zn-Mg alloy compared to zinc, Alu-Zn-Mg coated steel offers a larger area coverage per unit weight, similar to Al-Zn coatings but superior to pure zinc coatings.

In terms of economic efficiency, Alu-Zn-Mg coatings provide better value by offering extended service life and reducing the need for maintenance and replacement, especially in corrosive environments.

| Hot dip Alu-Zn-Mg Alloy Coated Steel | |

| Standard | JIS G3323/ASTM 1046/EN 10346/AS 1397 |

| Content | Low AL&MG : Zn-(0.5-3%) Al-(0.4-2%)Mg |

| Mid AL&MG: Zn-(3-13%) Al-(2-4%)Mg | |

| High AL Mid MG: Zn-(50-60%) Al-(2-4%)Mg | |

| Grades | DX51D+ZM/DX52D+ZM/DX53D+ZM |

| S220GD+ZM/S250GD+ZM/S280GD+ZM/S320GD+ZM/S350GD+ZM | |

| S400GD+ZM/S550GD+ZM | |

| HD300LAD+ZM/HD340LAD+ZM/HD380LAD+ZM | |

| HD420LAD+ZM/HD460LAD+ZM/HD500LAD+ZM/HD550LAD+ZM/HD700LAD+ZM | |

| SGMCC+ZM/SGHCD+ZM/SGH340D+ZM/SGH400D+ZM/SGH490D+ZM/SGH540D+ZM | |

| Coating | ZM20-ZM600g/m2 |

| Spangle | Regular spangle/ Zero spangle |

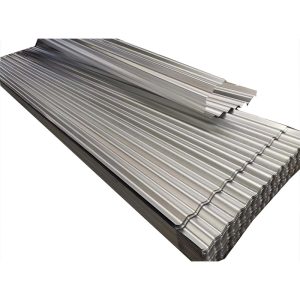

| Sizes | Thickness 0.8-4.5mm |

| Width: 580-1250mm | |

Applications

Hot Dip Alu-Zn-Mg Alloy Coated Steel is versatile and can be used both as a finished product and as a base for painted sheets. Its applications span across various industries, including:

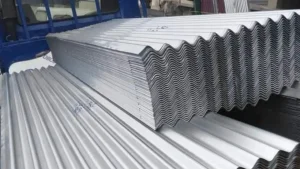

- Construction: Used in roofing, wall panels, ceilings, and roller doors for industrial buildings, power plants, sports facilities, airports, and residential homes.

- Agriculture: Suitable for structures in agricultural settings, such as greenhouses and livestock buildings.

- Transport: Utilized in automotive parts and electrical appliances due to its excellent formability and durability.

- Industrial and Infrastructure: Commonly used in civil construction (e.g., ceiling grids, perforated panels, cable trays), electrical and communication sectors (e.g., switchgear, transformer enclosures), and industrial cooling (e.g., cooling towers, large outdoor industrial air conditioners) .

Handling and Storage

Proper handling and storage are essential to maintain the quality of Alu-Zn-Mg coated steel. It should be stored in dry, well-ventilated areas away from chemical contaminants. Outdoor storage requires covering with waterproof materials. During transportation, the steel coils must be securely tied and protected to prevent damage. Care must be taken during loading and unloading to avoid scratching the surface. The use of rubber mounts and protective pads is recommended to minimize the risk of surface abrasion.

Advantages Over Other Coatings

The addition of magnesium in the Alu-Zn-Mg coating not only enhances corrosion resistance but also improves processing properties such as drawability, bending, painting, and welding. The coating’s hardness offers better scratch resistance, and its superior corrosion protection can replace stainless steel or aluminum in certain applications, offering cost savings and improved performance.

Conclusion

Hot Dip Alu-Zn-Mg Alloy Coated Steel represents a significant advancement in coated steel products, offering enhanced durability, excellent corrosion resistance, and a wide range of applications. Its unique combination of aluminum, zinc, and magnesium provides superior performance compared to traditional coatings, making it a preferred choice for many industries. As research and development continue, the versatility and applications of this innovative material are expected to expand further, solidifying its position in the market.