What mean of AZ150 G550 AFP Galvalume Aluzinc Steel Coil?

AZ150 means is galvalume aluzinc coating thickness;

G550 means is a high-strength steel grade of product standard EN 10125 or GB T 14978

AFP means stand of Surface treatment is Anti Fingerprint

Products Standard of hot dipped galvalume aluzinc steel coil

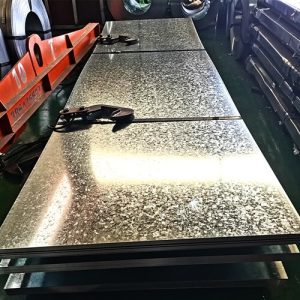

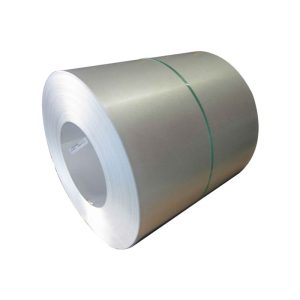

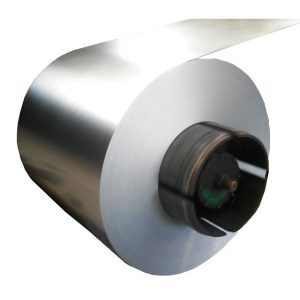

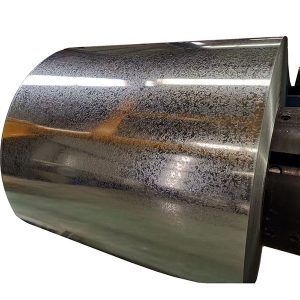

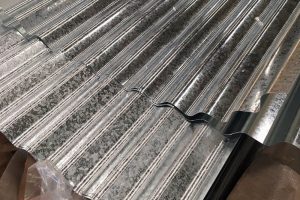

Hot dipped galvalume steel coil is an alloy steel plate composed of 55% Aluminum, 43.5% Zinc,1.5% Silicon. Hot dipped galvalume steel coil demonstrates stable anti-rust and anti-corrosion ability in various acid and alkaline, humid, and rainy environmental tests. So, galvalume steel coil has a wide range of applications in the industry. Mainly production standard as below:

Chinese Standard: GB T 2518

Japanese Standard: JIS G 3321

American Standard: ASTM A792

Europe Standard: EN 10346

Steel Grade of hot dipped galvalume aluzinc steel coil

According to different production standards, materials are divided into required materials. Main production standards and material comparisons are as follows:

Production Standard | ||||

| Steel Grade | GB T 2518 | JIS G 3321 | ASTM A792M | EN 10346 |

| Commercial | DX51D | SGLCC | CS Type B & C | DX51D |

| Drawing | DX52D | SGLCD | FS | DX52D |

| Deep Drawing | DX53D | SGLCD | DS | DX53D |

| Special Deep Drawing | DX54D | - | EDDS | DX54D |

| special deep drawing quality, (only +AS), heat resistance up to 800 °C; | DX55D | - | - | DX55D |

| Extra Deep Drawing | DX56D | - | - | DX56D |

| Super Deep Drawing | DX57D | - | - | DX57D |

High-Strength | S250GD | - | - | S250GD |

| S280GD | - | - | S280GD | |

| S320GD | SGLC400 | - | S320GD | |

| S350GD | SGLC440 | - | S350GD | |

| S450GD | SGLC490 | SS 345 Class 1 | S450GD | |

| S550GD | SGLC570 | SS 550 Class 1 | S550GD | |

Coating Code of hot dipped galvalume aluzinc steel coil

The products shall be supplied with coatings of Galvalume Aluzinc. Thicker coatings may limit the formability and weldability of the products. Therefore, the forming and weldability requirements should be taken into account when ordering the coating mass. The coating masses for all available grades are given in below Table:

| Standard | ||||

| GB T 2518 | JIS G 3321 | ASTM A792M | EN 10346 | |

| Coating Code | AZ30 | – | AZ30 | – |

| – | – | AZ35 | – | |

| AZ40 | – | AZ40 | – | |

| AZ50 | - | AZ50 | – | |

| – | - | AZ55 | – | |

| AZ60 | - | AZ60 | – | |

| AZ70 | AZ70 | AZ70 | – | |

| AZ80 | AZ90 | – | – | |

| AZ100 | - | AZ100 | AZ100 | |

| – | - | AZ110 | – | |

| AZ120 | AZ120 | AZ120 | – | |

| AZ150 | AZ150 | AZ150 | AZ150 | |

| – | AZ170 | AZ165 | – | |

| AZ180 | AZ185 | AZ180 | AZ185 | |

| AZ200 | AZ200 | AZ210 | – | |

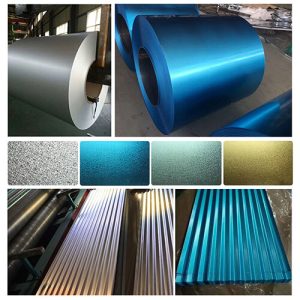

Surface Treatment of hot dipped galvalume aluzinc steel coil

There are many surface treatment processes for galvanized coils, and the surface treatment requirements are different according to different uses. The following are common surface treatments,

Hot-dip coated flat products receive one of the following surface treatments at the producer’s plant :

chemical passivation: C

oiling: O

chemical passivation and oiling CO

Anti Fingerprint AFP

The period of protection afforded is limited and depends on the atmospheric and storage conditions.

Hot-dip coated flat products are only supplied without surface treatment (untreated (U)) if expressively desired bythe purchaser on his own responsibility. in this case, there is increased risk of formation of corrosion products onthe surface during storage and transportation.

Chemical passivation protects the surface against humidity and reduces the risk of formation of corrosion productsduring storage and transportation.

Local colour variations as a result of this treatment is permissible and does not impair the quality.

Oiling treatment also reduces the risk of formation of corrosion products.

It shall be possible to remove the oil layer with a suitable degreasing solvent which does not adversely affect the coating.

Chemical passivation and oiling

Agreement may be reached on this combination of surface treatment in accordance with Oiling treament and Chemical Passivation if increased protection against the formation of corrosion products is required.

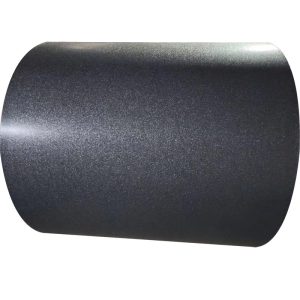

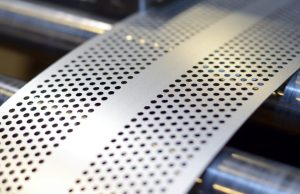

Anti Fingerprint

Our anti-fingerprint coating is an organic coating approximately 1 micron thick that creates an additional barrier

Not only does it prevent corrosion, it also provides a temporary protective coating during transportation and storage, it is antistatic and can produce

Ideal for gluing and painting as this treatment provides a smooth, pre-primed and ready-to-paint surface

Most paints. During the mechanical forming process, the coating acts as a dry lubricant, helping to reduce sticking on the tool.

In addition to the surface treatment mentioned above, it also includes Skin-pass, Chromate, Unoiled, Dry etc.

I hope the above information will help you understand AZ150 G550 AFP Galvalume Aluzinc Steel Coil. If you have any questions about AZ150 G550 AFP Galvalume Aluzinc Steel Coilor need to find a supplier, Witop Steel is happy to help you.

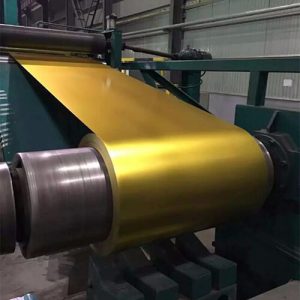

Recommend Prodcuts

-

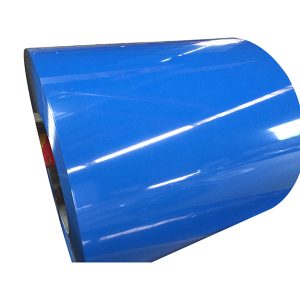

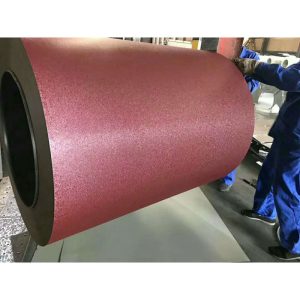

Galvalume/Aluzinc Steel Coil

Aluzinc steel coil Bobina Galvalume Steel Coil

Read moreRated 0 out of 5