When you buying steel coil for your industrial project, your choice directly affects productivity and durability. Selecting the wrong coil can lead to frequent repairs and higher maintenance costs. Industry studies show that alloy steel coils offer up to 50% more tensile strength and last 20–30% longer in demanding environments than traditional steel coils.

| Property | Alloy Steel Coils | Traditional Steel Coils |

|---|---|---|

| Tensile Strength | Up to 50% stronger | Standard strength |

| Durability | Lasts 20–30% longer | Requires more maintenance |

| Customization | High | Low |

| Maintenance Costs | Lower | Higher |

Matching coil type, thickness, and grade to your application ensures you get the best results for your investment.

Key Takeaways

- Choosing the right steel coil type impacts productivity and durability. Select coils based on your specific project needs.

- Alloy steel coils offer up to 50% more strength and last longer than traditional coils. Consider alloy options for demanding applications.

- Understand the differences between cold rolled, galvanized, and galvalume steel coils to match them with your project requirements.

- Always check coil thickness and width. These dimensions affect performance and cost, so choose wisely based on your application.

- Verify supplier credentials and certifications to ensure quality and compliance with industry standards. This step protects your investment.

- Request quotes from multiple suppliers to compare prices and services. Look beyond cost to find reliable partners.

- Inspect steel coils upon delivery for damage or defects. Quick action on issues helps maintain project timelines.

- Use a checklist to assess project requirements before purchasing. This practice helps avoid costly mistakes and ensures the right fit.

Steel Coil Basics

What Is Steel Coil?

You often see steel coils in industrial settings. These coils are long, continuous sheets of steel wound into a cylindrical shape. Manufacturers produce them using two main processes. Hot rolling creates coils with rougher surfaces and larger sizes. Cold rolling gives you smoother finishes and more precise measurements. Each method affects the final product’s quality and performance.

Here are some main characteristics that define steel coil in industrial contexts:

- Steel coils come as continuous sheets wound into rolls.

- Hot rolling results in rougher surfaces and larger coils.

- Cold rolling produces smoother finishes and tighter tolerances.

- You find steel coil applications in many industries, from automotive to construction.

Industrial Uses of Steel Coils

Steel coil uses span a wide range of industries. You rely on these products for their strength, flexibility, and adaptability. The table below shows how different industries use steel coils for specific purposes:

| Industry | Primary Steel Coil Uses |

|---|---|

| Automotive | Vehicle bodies, chassis, suspension |

| Construction | Structural beams, roofing, siding |

| Appliances | Casings, drums, components |

| HVAC | Ductwork, furnace components |

| Furniture | Chair bases, frames, storage |

| Energy | Transformer cores, towers |

| Packaging | Food containers, beverage cans |

| Agriculture | Equipment frames, components |

You see steel coil applications in vehicle manufacturing, where they form bodies and chassis. In construction, steel coil uses include making beams, roofing, and siding. Appliance makers depend on steel coils for durable casings and drums. HVAC systems use steel coil for ductwork and furnace parts. Even furniture, energy, packaging, and agriculture industries rely on steel coil applications for frames, cores, and containers.

Why Choosing the Right Steel Coil Matters

Selecting the right steel coil for your project ensures you get the best results. If you choose the wrong type, you may face problems like poor performance or higher costs. Each industry has unique steel coil uses, so you must match the coil’s properties to your needs. For example, construction projects need coils with high strength and weather resistance. Appliance manufacturers look for coils with smooth finishes and precise dimensions.

Tip: Always review your project’s requirements before selecting a steel coil. This step helps you avoid costly mistakes and ensures your finished product meets industry standards.

When you understand steel coil basics, you make better decisions for your business. You improve productivity, reduce waste, and increase the lifespan of your products.

Types of Steel Coils

When you choose steel coils for your project, you need to understand the main types available. Each type offers unique properties and fits different industrial needs. The table below highlights the differences among cold rolled, galvanized rolled, and galvalume steel coils.

| Type of Steel Coil | Production Process | Key Properties | Applications |

|---|---|---|---|

| Cold Rolled Steel Coil | Produced below crystallization temperature with controlled rolls | High dimensional accuracy, smooth finish, strong | Automotive parts, precision components |

| Galvanized Steel Coil | Immersed in molten zinc to form a protective layer | Excellent corrosion resistance, long service life | Construction, outdoor structures |

| Galvalume Steel Coil | Hot-dip process with aluminum and zinc coating | Superior durability, heat and corrosion resistance | Roofing, siding, high-moisture environments |

Cold Rolled Steel Coil

You use cold rolled steel coil when you need high precision and a smooth surface. Manufacturers produce this coil by rolling steel below its crystallization temperature. This process gives you a product with tight tolerances and a polished finish. Cold rolled steel coil works well for automotive parts and other applications where exact dimensions matter. You get high tensile strength and a surface that looks clean and professional. Compared to hot rolled steel, cold rolled steel coil offers better formability after annealing and more consistent quality.

Galvanized Rolled Steel Coil

Galvanized steel coil stands out for its corrosion resistance. You get this coil by dipping steel into molten zinc. The zinc layer forms a barrier that protects the steel from rust and oxidation. Even if the surface gets scratched, the zinc coating continues to protect the steel underneath.

This sacrificial effect means your galvanized steel coil lasts longer, even in tough environments. In average conditions, galvanized steel coil can last over 50 years. In harsh or aggressive settings, it often exceeds 20 years of service. You see galvanized steel coil used in construction, outdoor structures, and any place where moisture or weather exposure is a concern. The durability and low maintenance needs make galvanized steel coil a smart choice for many projects.

Galvalume Steel Coil

Galvalume steel coil combines the benefits of zinc and aluminum coatings. You get a product that resists corrosion and heat. The hot-dip process gives galvalume steel coil a tough outer layer that stands up to moisture, humidity, and high temperatures. You can use galvalume steel coil for roofing, siding, and other exterior applications. It keeps its shape and strength even when exposed to heat or harsh weather. Galvalume steel coil is ideal for environments where you need both durability and long-term performance.

Tip: Always match the type of steel coil to your project’s environment and performance needs. This step helps you avoid costly repairs and ensures your finished product meets industry standards.

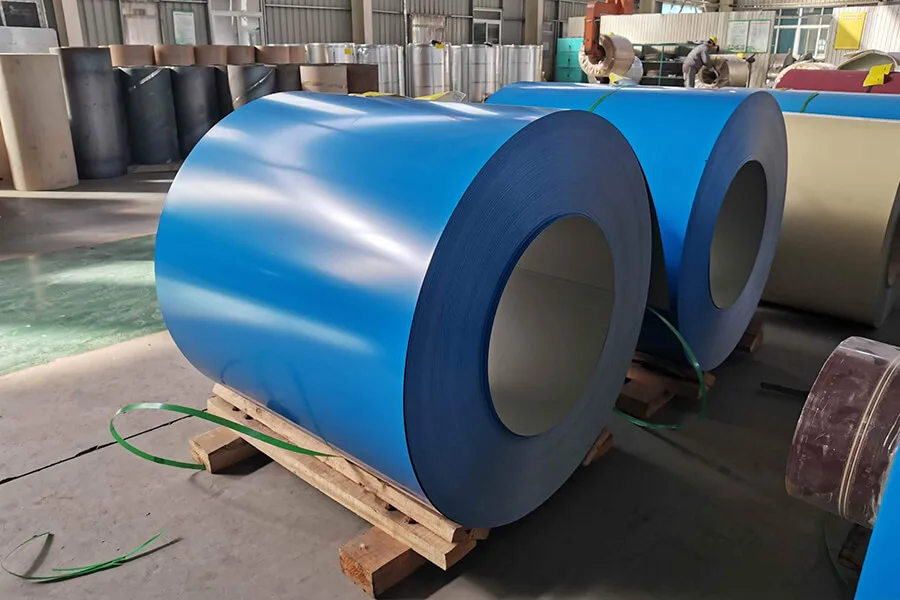

Prepainted Steel Coils

You often see prepainted steel coils in industries that demand both performance and appearance. Manufacturers apply a layer of paint or coating to the steel surface before forming the coil. This process creates a product that stands out for its durability and visual appeal. You can choose from a wide range of colors, patterns, and finishes to match your project’s needs.

Prepainted steel coils offer several advantages that make them popular in industrial manufacturing:

- High performance in harsh weather conditions prevents cracking and peeling.

- Lightweight construction makes handling and transportation easier.

- Impressive structural integrity supports demanding applications.

- Enhanced corrosion resistance protects against rust and moisture.

- Aesthetic options allow you to select colors and finishes that suit your brand or project.

- Cost-effective production reduces the need for post-painting and lowers maintenance expenses.

- Environmentally friendly manufacturing produces less waste compared to post-painted materials.

- Minimal maintenance requirements help you save time and money over the lifespan of your products.

You find prepainted steel coils used in construction, appliance manufacturing, automotive parts, and packaging. These coils work well for roofing panels, wall cladding, garage doors, and even furniture. You get a product that resists fading, chipping, and corrosion, even when exposed to sunlight, rain, or chemicals.

Tip: When you select prepainted steel coils, you improve your project’s appearance and reduce long-term costs. You also support sustainability by choosing materials that generate less waste.

Prepainted Galvanized steel coil

Prepainted galvanized steel coil combines the benefits of zinc coating with a durable paint layer. You get a coil that resists rust and corrosion, even in high humidity or moisture-rich environments. The zinc coating forms a strong barrier, while the paint adds another layer of protection and color.

You often use prepainted galvanized steel coil for exterior building panels, roofing, and siding. These coils retain their color and finish for years, requiring little maintenance. You save on repair costs and avoid frequent repainting. The lightweight design makes installation faster and easier, which helps you complete projects on schedule.

Prepainted galvanized steel coil also supports environmental goals. The manufacturing process produces less waste, and the coils last longer than traditional painted materials. You can choose from many colors and finishes to match your design vision.

Note: Always check the coating thickness and paint quality before you buy prepainted galvanized steel coil. High-quality coatings ensure better performance and longer service life.

You improve your project’s durability, appearance, and cost efficiency when you choose prepainted steel coils. These products help you meet industry standards and deliver results that last.

Key Specifications for Buying Steel Coil

Coil Thickness and Width

When you select steel coils for your project, you must pay close attention to thickness and width. These dimensions affect how well the material fits your application and how it performs under stress. For example, automotive manufacturers often use thinner coils for body panels, while construction projects require thicker coils for structural components. You can see the typical industry standards for steel coil dimensions in the table below:

| Dimension Type | Range |

|---|---|

| Width | 1000 mm – 1500 mm |

| Thickness | 0.3 mm – 16 mm |

| Inner Diameter | 508 mm or 610 mm |

| Weight | 3 – 25 tons |

The thickness of steel coils impacts several key factors:

- Thicker coils provide greater strength, making them ideal for structural components in construction and heavy machinery.

- Thinner coils offer more flexibility, which suits automotive body panels and lightweight metal building components.

- The thickness you choose also affects your costs. Thicker coils increase both production and shipping expenses.

Tip: Always match the thickness and width of your steel coils to the specific requirements of your project. This step ensures you get the right balance between strength, flexibility, and cost.

Coil Weight and Load Capacity

You need to consider coil weight and load capacity as part of your key buying considerations. The weight of steel coils can range from small coils at 500–2000 kg to large coils weighing 5–30 tons or more.

| Coil Size | Weight Range |

|---|---|

| Smaller Coils | 500 – 2000 kg |

| Larger Coils | 5 – 30 tons or more |

Choosing the right coil weight helps you optimize production and maintain safety. Here are some important points to keep in mind:

- The run time between coil changes depends on coil weight. Heavier coils allow longer production runs, reducing downtime.

- You must ensure your cranes or lift trucks can handle the maximum coil weight. Overloading equipment can cause accidents and damage.

- Heavier coils require cranes with higher rated capacities. For example, a 30-ton coil needs a crane that can safely lift above that weight.

- The specifications of your steel coils directly influence the design and capacity of your overhead crane systems.

Note: Always check your facility’s lifting equipment before ordering large steel coils. This step helps you avoid costly delays and ensures safe handling.

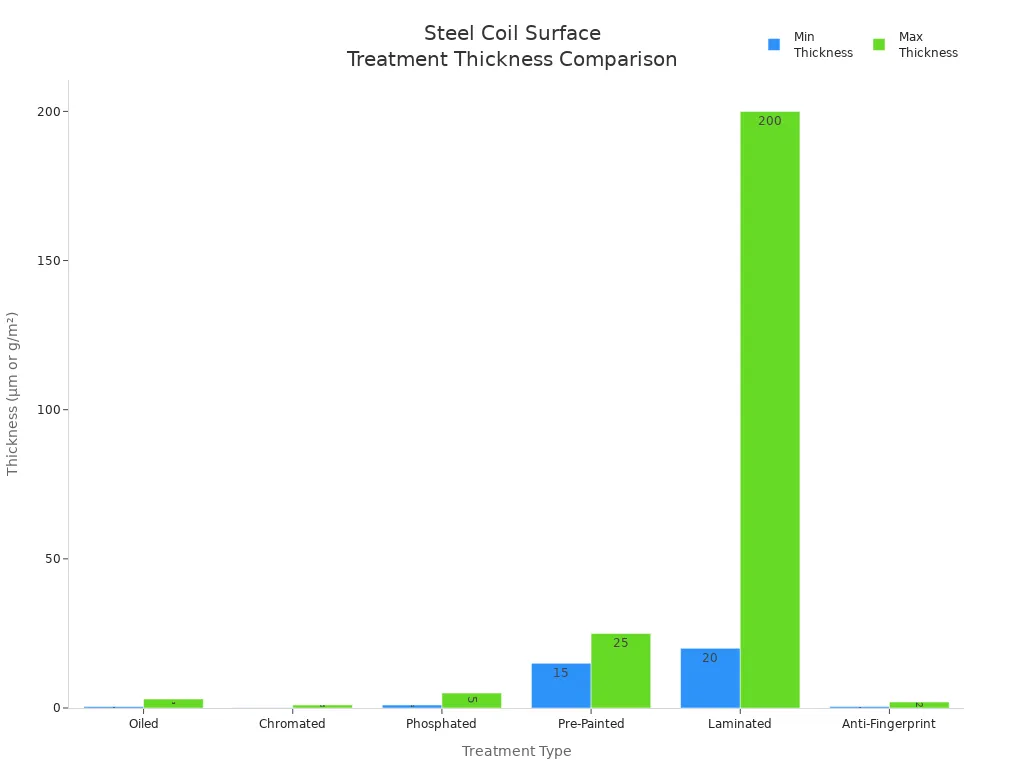

Surface Finishes and Coatings

Surface finishes and coatings play a major role in steel coil uses. They protect the steel from corrosion, improve appearance, and enhance performance. You can choose from several common finishes and coatings, each with unique benefits:

- Oiled surface prevents white rust during storage or transport.

- Chromated (passivation) improves corrosion resistance and helps paint stick better.

- Phosphated finish enhances paint adhesion and corrosion protection.

- Painted or coated steel coils add color, UV resistance, and extra protection.

- Laminated finishes provide scratch resistance and decorative appeal.

- Anti-fingerprint coatings keep surfaces clean and smudge-free.

The table below summarizes the main treatments, their thickness, and key benefits:

| Treatment | Thickness | Key Benefits |

|---|---|---|

| Oiled | 0.5–3 g/m² | Prevents white rust, easy to clean |

| Chromated | 0.1–1.0 µm | Enhances paint adhesion, RoHS-compliant |

| Phosphated | 1–5 µm | Improves corrosion resistance |

| Pre-Painted | 15–25 µm (per side) | UV resistance, customizable colors |

| Laminated | 20–200 µm | Scratch-proof, decorative finishes |

| Anti-Fingerprint | 0.5–2 µm | Smudge-free surface, aesthetic retention |

Different coatings also impact the longevity and maintenance needs of steel coils. For example, zinc coatings provide sacrificial corrosion protection and last 500–600 hours in salt spray tests. Aluminum-zinc coatings offer even higher durability, with up to 2500 hours of protection. PVDF coatings deliver high weather resistance and retain color for 20–30 years, making them ideal for exterior construction and high-grade steel applications.

| Coating Type | Corrosion Resistance | Durability (Hours) | Color Retention (Years) |

|---|---|---|---|

| Zinc (Z) | Sacrificial protection | 500–600 | N/A |

| Al-Zn (AZ) | Barrier + galvanic | 2000–2500 | N/A |

| PVDF | High weather resistance | N/A | 20–30 |

Tip: Choose the right surface finish and coating based on your steel coil uses. This decision helps you reduce maintenance, extend product life, and meet industry standards for structural components.

When you understand these key specifications, you make better choices for your steel coils. You ensure your products meet the demands of construction, manufacturing, and other industrial applications. You also get the best value from high-strength steel and high-grade steel, especially when you focus on durability and corrosion protection.

Certification and Compliance

You must check certifications and compliance before you buy steel coils for your project. Certifications show that the steel meets strict quality, safety, and performance standards. These standards protect your business from costly mistakes and help you pass inspections with ease.

Here is a table of common certifications you may need to look for:

| Certification Type | Description |

|---|---|

| ASTM Certification | Ensures hot rolled steel coils meet quality and performance criteria, such as chemical makeup and strength. |

| ISO Certification | Shows a commitment to quality management and improvement. Includes ISO 9001, ISO 14001, and ISO 45001. |

| CE Certification | Required for products in the European Economic Area. Confirms health, safety, and environmental protection. |

| Mill Test Certificate | Gives you detailed information about the steel coil’s properties. Proves quality and compliance. |

| Construction Industry Certifications | Guarantees structural integrity and safety for building projects. Sets minimum strength and impurity levels. |

| Automotive Industry Certifications | Confirms materials meet strict standards for automotive parts. Ensures safety and reliability. |

You should always ask your supplier for these certificates. They help you avoid low-quality steel and ensure your project meets industry rules.

Compliance standards also shape how you buy steel coils. When you choose certified suppliers, you get many benefits:

- You receive steel coils with consistent thickness and strength.

- You meet safety standards for your region or industry.

- You get reliable paperwork for inspections and audits.

- You reduce project delays and material defects.

- You build trust with your clients and partners.

Tip: Always keep copies of your steel coil certificates. These documents help you prove compliance during inspections and protect your business from legal issues.

If you work in construction or automotive industries, you must follow strict rules. Certified steel coils help you pass inspections and keep your projects on track. You also lower your risk of accidents and costly repairs.

When you focus on certification and compliance, you make smart choices for your business. You protect your reputation, save money, and deliver safe, high-quality results.

How to Buy Steel Coil for Industrial Applications

Assess Project Requirements

You need to start with a clear understanding of your project’s needs before you buy steel coil. This step helps you avoid costly mistakes and ensures your steel coil uses match your goals. Begin by identifying the environment where you will use the steel. For example, construction projects in coastal areas require higher corrosion resistance. You should also consider the load the steel will bear and the appearance you want to achieve.

Here is a table to help you organize the main factors:

| Factor | Description |

|---|---|

| Stainless Steel Grade | Different grades like 304 and 316 offer varying corrosion resistance, crucial for specific environments. |

| Coil Thickness | Thicker coils are better for load-bearing applications, while thinner ones suit non-structural uses. |

| Surface Finish | The finish affects both aesthetics and durability; polished finishes may enhance appearance but could reduce strength in harsh conditions. |

| Environmental Conditions | The environment impacts corrosion resistance, making it essential to consider where the coil will be used. |

You should write down your requirements for each factor. This process helps you communicate clearly with suppliers and ensures you get the right steel coil for your industrial applications.

Tip: Always match your steel coil uses to the specific demands of your project. This habit increases efficiency and reduces waste.

Select Coil Type and Grade

Once you know your project requirements, you can select the right coil type and grade. This choice affects the performance, cost, and lifespan of your steel coils. Engineers use several steps to determine the best grade for each application:

- Assess the complexity of forming operations. If your project involves deep drawing or bending, you need a grade with high formability.

- Review the part design and geometry. Complex shapes may require more flexible steel.

- Decide on the surface finish requirements. Some applications need a smooth, polished look, while others focus on durability.

- Consider your budget. Over-specifying can increase costs without adding value.

- Check for welding and machining needs. Some grades perform better during these processes.

- Evaluate your supply chain and supplier capability. Reliable suppliers ensure you get the grades you need on time.

You should always balance performance with cost. For example, high-grade stainless steel works well for harsh environments but may not be necessary for indoor, non-structural steel coil uses.

Note: If you are unsure about the best grade, ask your supplier for recommendations based on your project details.

Request Quotes and Compare Suppliers

After you select the coil type and grade, you need to request quotes from multiple suppliers. Comparing offers helps you find the best value and ensures you get high-quality steel coils for your project. Do not focus only on price. You should also check the supplier’s reliability, technical support, and ability to meet your needs.

Use this table to compare key criteria:

| Criteria | Description |

|---|---|

| Quality and Certifications | Ensure the steel meets industry standards and has necessary certifications like ISO 9001. |

| Technical Expertise and Support | Look for suppliers with knowledgeable staff who can provide guidance on material selection and issues. |

| Product Range and Customization | Check if the supplier can meet specific project needs with a variety of steel types and custom options. |

| Value-Added Processing Services | Consider suppliers that offer processing services to enhance efficiency and reduce production costs. |

| Reliability and Customer Service | Evaluate the supplier’s reputation for on-time delivery and quality customer support. |

You should ask for references or case studies to check the supplier’s track record. Reliable suppliers help you avoid delays and ensure your steel coil uses meet industry standards. You can also request samples to verify quality before you buy steel coil in large quantities.

Tip: Always choose suppliers who offer strong technical support and have a reputation for reliability. This decision protects your investment and keeps your project on schedule.

When you follow these steps, you make the process to buy steel coil for industrial applications simple and effective. You get the right material, avoid common pitfalls, and ensure your steel coil uses deliver the results you expect.

Place Orders and Manage Delivery

You have selected your steel coil supplier and compared quotes. Now, you need to place your order and manage delivery to ensure your project stays on track. This step requires careful planning and attention to detail.

Start by confirming all order details with your supplier. Double-check the coil type, grade, thickness, width, and surface finish. Make sure the quantity matches your project needs. Ask for a written confirmation or purchase order. This document helps you avoid misunderstandings and keeps both you and your supplier accountable.

Next, discuss delivery timelines. Ask your supplier for an estimated delivery date. Request tracking information if available. Reliable suppliers provide clear schedules and communicate any changes quickly. You should also ask about packaging methods. Proper packaging protects your steel coils from damage during transport.

When your steel coils arrive, inspect them right away. Look for signs of damage, rust, or incorrect labeling. If you find any issues, contact your supplier immediately. Take photos and keep records. Quick action helps you resolve problems faster and protects your investment.

Safe handling is essential. Steel coils are heavy and can cause injuries if not managed correctly. You should:

- Wear appropriate Personal Protective Equipment (PPE) such as gloves, safety shoes, and helmets.

- Use cranes, forklifts, or coil lifters designed for heavy loads.

- Store steel coils on stable, flat surfaces to prevent rolling or falling.

- Keep walkways clear and mark storage areas to avoid accidents.

You also need a good inventory management system. Track the quantity and location of each coil. This practice helps you avoid shortages and keeps your project running smoothly. Digital inventory tools make this process easier and reduce human error.

Building strong relationships with reliable suppliers pays off. Good suppliers deliver on time and respond quickly to your needs. They help you solve problems and keep your project moving forward.

Tip: Review your delivery and storage procedures with your team before the coils arrive. Clear communication and safety training reduce risks and improve efficiency.

By following these steps, you ensure your steel coils arrive safely and on schedule. You protect your workers, your materials, and your project timeline.

Avoiding Common Mistakes When Buying Steel Coils

Overlooking Specifications

You can avoid many problems by paying close attention to specifications. If you skip this step, you risk choosing the wrong thickness, width, or coating for your project. Each detail matters because steel coil uses change with every application. For example, a coil that works for roofing may not suit automotive parts. You need to check the mechanical properties, surface finish, and coating type before you make a decision. Write down your requirements and compare them with the product data sheet. This habit helps you match steel coil uses to your project’s needs. If you overlook specifications, you may face delays, extra costs, or even safety issues.

Tip: Always double-check the technical sheet for each order. This step keeps your steel coil uses on track and prevents costly mistakes.

Ignoring Supplier Credentials

You should always verify your supplier’s credentials before you buy steel coils. Reliable suppliers follow strict standards and deliver consistent quality. You can check their compliance with international standards using the table below:

| Compliance Standard | Description |

|---|---|

| ISO 9001 | Quality management systems |

| ISO 14001 | Environmental responsibility |

| API, EN, ASTM A568, JIS G3302 | Product-specific standards |

You can also look at supplier performance metrics:

| Metric | Target Benchmark | Example Supplier |

|---|---|---|

| On-time Delivery Rate | ≥94.9% | Shandong Zhongsheng Materials Co., Ltd. – 100% |

| Response Time | ≤2 hours | Shandong Hongtai Metal Products Co., Ltd. – ≤1 hour |

To ensure you get the right steel coil uses, you should:

- Request physical samples for testing.

- Verify surface finish uniformity and coating adhesion.

- Conduct factory audits, either virtually or in-person.

These steps help you avoid low-quality materials and late deliveries. You protect your project and keep your steel coil uses reliable.

Mismatching Coil to Application

You need to match the coil type to your specific application. If you choose the wrong coil, you may face handling difficulties. Some steel coil uses require lighter coils, while others need heavy-duty options. Using the wrong type can create safety hazards. Steel coils have sharp edges and heavy weight, which can cause injuries if mishandled. Poor handling can also lead to product defects, such as dented edges or scratched coatings. These problems lower the quality of your finished product.

If you use incorrect materials or grades, you may damage your machines. Operational issues can stop production and increase costs. You should always review your steel coil uses and select the right type for each job. This practice keeps your workplace safe and your products strong.

Note: Matching the right coil to your application improves safety, reduces waste, and ensures your steel coil uses meet industry standards.

Actionable Tips for Steel Coil Buyers

Quick Checklist for Buying Steel Coil

You can make your buying process smoother by following a simple checklist. This list helps you avoid mistakes and ensures your steel coil uses match your project needs. Review each item before you place an order:

- Environment: Identify the corrosion category for your project, such as C1 for dry indoor spaces or C5 for harsh, marine environments.

- Lifespan: Decide how many years of service you expect from the steel coil. Longer lifespans may require special coatings or grades.

- Fabrication: Check if you will deeply form, bend, or cut the coil. Some steel grades handle shaping better than others.

- Appearance: Determine if color consistency and gloss matter for your application. Projects with visible surfaces often need strict appearance standards.

- Certification: Confirm if your project requires specific test reports or compliance documents. Certifications help you meet industry rules and pass inspections.

Tip: Write down your answers for each checklist item. This habit makes it easier to communicate with suppliers and select the right steel coil for your needs.

Best Practices for Industrial Success

You can achieve better results and avoid common pitfalls by following proven best practices when buying steel coils. These steps help you get the most value from your investment and keep your operations running smoothly.

- Track market prices and time your purchases to get the best deals.

- Choose suppliers with strong reputations and reliable quality control.

- Plan for efficient delivery and handle customs paperwork early.

- Mix short-term and long-term buying strategies to cover all your needs.

- Negotiate financing options that bundle procurement with project funding.

- Focus on quality assurance by checking certifications and inspecting shipments.

- Protect your budget by locking in exchange rates and using indexed contracts.

- Buy in bulk and combine shipments to save on costs.

- Prepare for supply chain delays by keeping extra stock and working with more than one supplier.

- Use secure payment systems and match payments to project milestones.

- Include environmental standards and regular audits in your process.

- Use technology like automation and data analytics to track your steel coil uses and inventory.

- Review your buying process every quarter and adjust to market changes.

Note: Following these best practices helps you avoid delays, reduce costs, and improve the quality of your steel coil uses. You also build a stronger supply chain and meet industry standards for steel.

You can use this checklist and these best practices to make smarter decisions. Your projects will benefit from better planning, higher quality, and fewer surprises.

When you buy steel coil for your project, you set the stage for success. Follow these steps to make smart choices:

- Understand the specifications and standards for each coil.

- Check your supplier’s reputation and capabilities.

- Consider lead times, shipping, and tariffs before you buy steel coil.

Using a structured guide helps you avoid delays and build strong supplier relationships. Apply these tips to your next project for better results.

FAQ

What is the difference between hot rolled and cold rolled steel coil?

Hot rolled steel coil has a rougher surface and looser tolerances. Cold rolled steel coil gives you a smoother finish and more precise dimensions. You should choose based on your project’s need for appearance and accuracy.

How do I know which steel coil grade to choose?

You should match the grade to your application’s strength, corrosion resistance, and formability needs. Ask your supplier for recommendations if you are unsure. Always check your project’s technical requirements first.

Can I order custom sizes for steel coils?

Yes, most suppliers offer custom widths, thicknesses, and coatings. You should provide exact measurements and specifications when you request a quote.

How do I store steel coils safely?

Store steel coils on flat, stable surfaces. Use coil racks or cradles. Keep coils dry and covered to prevent rust. Always follow your facility’s safety guidelines.

What certifications should I check before buying?

Always look for certifications like ISO 9001, ASTM, or CE. These prove the steel meets quality and safety standards. Ask for mill test certificates with each order.

How do I prevent rust on steel coils during storage?

You should keep coils in a dry, well-ventilated area. Use oiled or coated coils for extra protection. Inspect regularly for moisture or damage.

What should I do if my steel coil order arrives damaged?

Inspect the coils immediately. Take photos of any damage. Contact your supplier right away and provide documentation. Most suppliers will resolve issues quickly if you report them promptly.