Introduction

C purlins are necessary components in structural frameworks, particularly for roofing systems. Their lightweight, versatile, and cost-effective nature makes them indispensable for both industrial and residential building projects.

Among the different types available, galvanized C purlins excel due to their enhanced durability and resistance to corrosion.

In this detailed blog post, we will explore everything you need to know about C purlins, including roofing C purlins, C purlin sizes, C purlin weight, C channel purlins, and standard C purlin sizes.

C Purlins: What are C purlins?

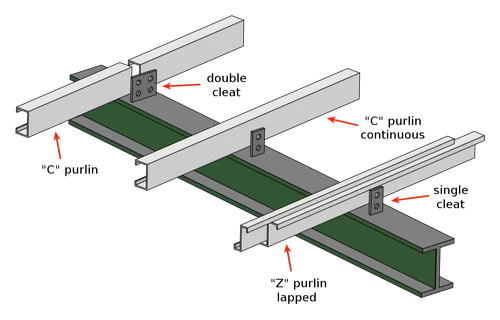

In steel construction, the term purlin typically refers to roof framing members that span parallel to the building eave and support the roof decking or sheeting. The steel purlins are in turn supported by rafters or walls.

C purlins get their name from their “C” shaped cross-section and are typically made of cold-formed steel. Their main function is to provide structural support to the roof and wall panels, transferring loads to the building’s frame or primary structural members.

The shape of C purlins makes them ideal for supporting roof coverings, especially in metal buildings, warehouses, commercial spaces, and even in some residential structures.

Why we Use Galvanized C Purlins?

When C purlins are galvanized, they are coated with a layer of zinc to prevent rusting and corrosion. This makes them ideal for outdoor use, where they are exposed to moisture, temperature fluctuations, and other environmental elements.

Advantages of Galvanized C Purlins: The Benefits

- Corrosion Resistance: The zinc coating provides superior protection against moisture and oxidation.

- Low Maintenance: Galvanized steel requires little to no maintenance over its lifespan.

- Longer Life: A galvanized C purlin can last decades without significant degradation.

- Cost-Effective: Reduced maintenance and longer life result in lower life-cycle costs.

- Sustainability: Steel is recyclable, and galvanized steel maintains its properties through recycling.

Roofing C Purlins: Backbone of Metal Roofing Systems

One of the most common applications of C purlins is in roofing systems. Roofing C purlins act as secondary framing members that provide support for roof decking, insulation panels, or metal sheeting.

How C Purlins Work in Roofing?

- They span between the main frames of the structure.

- Roof panels are attached directly to them.

- They distribute the weight of the roof and environmental loads like snow and wind to the structural frame.

Advantages in Roofing

- Quick and easy installation.

- Reduction in overall roof weight

- Compatibility with various roofing materials and insulation systems

C Channel Purlins: Similarities and Differences

C channel purlins are another name for C purlins, commonly used interchangeably. The term “channel” emphasizes the shape — a C or U-shaped profile with two flanges and a web.

C Purlin Sizes: Standard and Custom Options

C purlins come in a range of sizes to accommodate different load requirements and building designs. They are typically manufactured using high-strength cold-formed steel, available in different thicknesses and depths.

Factors Affecting Size Selection

- Span length

- Roof pitch

- Type of roofing material

- Wind and snow load

- Structural layout

Galvanized C Purlins Weight: What You Need to Know

The weight of C purlins plays a significant role in structural design. It determines not only the ease of installation but also the load it places on the primary structure.

How Is Galvanized C Purlin Weight Calculated?

The weight depends on:

- Size of the purlin (depth, width, thickness)

- Length of the purlin

- Density of steel (typically 7.85 g/cm³)

You can estimate weight using the formula:

Weight (kg/m) = (Perimeter × Thickness × 7.85)

Or refer to manufacturer data sheets, which list the weight per meter for various sizes.

Example Weights:

| Size (mm) | Thickness (mm) | Approx Weight (kg/m) |

| 150 x 60 x 20 | 1.6 | 5.1 |

| 200 x 70 x 20 | 2.0 | 7.2 |

| 250 x 75 x 20 | 2.5 | 9.5 |

| 300 x 75 x 20 | 3.0 | 12.3 |

Note: Always use structural software or engineering tables for precise calculations.

Applications of Galvanized C Purlins

Roofing Structures: The most common use in both industrial and residential buildings.

Wall Cladding Support: Acts as girts to support wall panels.

Solar Panel Structures: Frameworks for solar panels on roofs and open fields.

Carports and Canopies: Lightweight and durable framework solutions.

Warehouse and Factory Buildings: Provides structural integrity in large-span structures.

Installation Tips for C Purlins

Proper installation of C purlins ensures long-term performance and safety.

Tips:

- Ensure the purlins are aligned properly and securely fastened to the primary structure.

- Use anti-corrosion fasteners, especially with galvanized purlins.

- Space them correctly according to the load-bearing requirements.

- Use bracing where necessary to prevent buckling.

- Always follow the structural engineer’s recommendations.

Cost Considerations

The cost of C purlins, especially galvanized ones, depends on:

- Steel grade

- Size and thickness

- Length

- Zinc coating thickness (e.g., Z120, Z275)

- Quantity ordered

On average, prices range from $1.20 to $3.50 per meter, depending on specifications and market conditions. Bulk purchases often attract discounts.

Maintenance and Longevity

Galvanized C purlins require minimal maintenance. However, periodic inspections are essential to:

- Check for signs of rust or corrosion at connection points.

- Ensure no warping or structural damage.

- Tighten or replace fasteners if needed.

- Properly installed and maintained, galvanized C purlins can last 30 years or more.

C Purlin Roof Systems: A Complete Package

A C purlin roof is often part of a prefabricated steel building system. The entire roofing system includes:

- Primary steel frames (I-beams or columns)

- Secondary members (C or Z purlins)

- Roof decking (corrugated metal sheets)

- Insulation layers (optional)

- Fasteners and accessories

Together, these components create a robust, weather-resistant, and economical roofing solution.

Conclusion

C purlins, especially galvanized C purlins, are a staple in modern construction due to their strength, affordability, and ease of installation. Whether you’re planning a small shed or a large commercial building, choosing the right C purlin size, understanding C purlin weight, and selecting standard C purlin sizes can make a significant difference in your structure’s stability and cost.

From roofing C purlins to C channel purlins, their flexibility in design and function continues to make them a top choice among builders and engineers worldwide.

Qingdao Witop Steel group are fully convinced that the quality products assist the success of our customers. The leading products are WITOP brand galvanized steel sheet, galvalume/alu-zinc steel sheet and color coated steel sheet, which gained famous brand products worldwide.

Focusing on “stabilizing high quality and establishing brand”, Witop Steel has established a stable raw material supply and sales network in more than 100 countries and 180 customers, and enjoys a high reputation in the domestic and international markets.