You play a vital role in shaping the future of infrastructure when you choose materials that deliver lasting value. Galvanized steel strip stands out for its remarkable corrosion resistance, ensuring your structures withstand harsh environments. You benefit from its durability, which reduces the need for frequent replacements in large-scale projects. Its versatility allows you to meet diverse construction demands with confidence. WITOP’s commitment to quality means you receive a product engineered for reliability, elevating every big build you undertake.

Key Takeaways

- Galvanized steel strip offers excellent corrosion resistance, protecting your structures from rust and extending their lifespan.

- The hot-dip galvanizing process ensures a uniform zinc coating, enhancing durability and maintaining protective qualities over time.

- WITOP provides galvanized steel strip in various hardness levels, allowing you to choose the right option for your project’s specific needs.

- Different spangle types are available, giving you flexibility in both appearance and performance for your construction projects.

- Using galvanized steel strip reduces maintenance costs, saving you time and money on repairs throughout the life of your infrastructure.

- This material is versatile, suitable for applications in construction, automotive, and utility sectors, adapting to various project requirements.

- Galvanized steel strip is environmentally friendly, being fully recyclable and produced with energy-efficient methods, supporting sustainable building practices.

- WITOP’s commitment to quality ensures you receive reliable materials that meet strict industry standards, enhancing the safety and performance of your builds.

Galvanized Steel Strip Overview

Hot Dipped Galvanizing Process

Continuous Coating

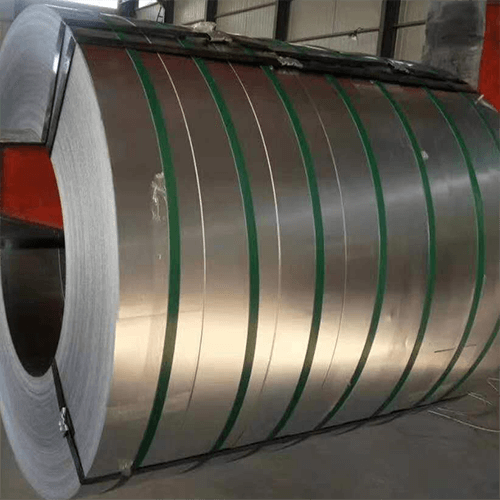

You rely on materials that offer consistent quality. The hot dipped galvanizing process gives you a galvanized steel strip with a uniform zinc coating. WITOP uses advanced manufacturing lines to immerse steel in molten zinc. This method creates a continuous layer that covers every surface. You get a product that resists damage and maintains its protective qualities over time.

Zinc Protection

Zinc acts as a shield for your steel. When you choose galvanized steel strip, you benefit from a barrier that prevents rust and corrosion. The zinc coating reacts with the environment before the steel does, keeping your structures safe. WITOP’s process ensures the zinc layer is thick and even, so you can trust the longevity of your materials.

Product Variants

Hardness Levels

You need options that fit your project’s demands. WITOP offers galvanized steel strip in three hardness levels:

- Softy: Easy to shape and bend, perfect for intricate designs.

- Semi-Hard: Balances flexibility and strength, suitable for general construction.

- Full Hard: Maximum strength for heavy-duty applications.

You select the hardness that matches your requirements, ensuring your build stands up to stress and wear.

Spangle Types

Surface appearance matters in many projects. WITOP provides several spangle types for galvanized steel strip. Each type offers a distinct look and performance:

| Spangle Type | Description | Typical Use Cases |

|---|---|---|

| Zero Spangle | Smooth, matte finish | Painted surfaces, interiors |

| Small Spangle | Fine, subtle pattern | Decorative panels |

| Regular Spangle | Standard, visible pattern | Roofing, outdoor use |

| Big Spangle | Large, pronounced pattern | Industrial, exposed areas |

You choose the spangle that fits your aesthetic and functional needs. WITOP’s customization lets you match the steel to your project’s specifications.

Tip: Selecting the right hardness and spangle type helps you optimize both performance and appearance in your big builds.

You gain flexibility and control when you work with WITOP’s galvanized steel strip. The range of options ensures you meet every challenge with confidence.

Key Benefits for Infrastructure

Corrosion Resistance

Rust Prevention

You protect your projects from rust when you choose galvanized steel strip. The zinc coating acts as a barrier, stopping moisture and oxygen from reaching the steel surface. This shield prevents rust from forming, even in environments with high humidity or exposure to water. You maintain the integrity of your structures and avoid costly repairs.

Longevity

You extend the lifespan of your infrastructure with galvanized steel strip. Studies show that this material resists corrosion and stands up to harsh environmental factors. You benefit from its durability, which means your bridges, buildings, and pipelines last longer. The reliable performance of galvanized steel strip makes it a trusted choice for major projects.

Mechanical Strength

Yield and Tensile Strength

You demand materials that can handle stress and heavy loads. Galvanized steel strip delivers impressive mechanical properties. You get yield strength between 300 and 400 MPa and tensile strength ranging from 300 to 550 MPa. These values ensure your structures remain stable and secure, even under demanding conditions.

High Heat Tolerance

You face challenges when your projects encounter high temperatures. Galvanized steel strip maintains its protective qualities and mechanical strength in these environments. The hot-dip galvanization process immerses steel in molten zinc at around 460 degrees Celsius, creating a robust surface layer. You avoid deformation and loss of strength, even when exposed to heat up to 315 degrees Celsius.

- Thermal treatment changes the internal properties of steel, but galvanization provides reliable surface protection.

- You design equipment with confidence, knowing that galvanized steel strip withstands temperature fluctuations without compromising performance.

Cost Efficiency

Maintenance Savings

You reduce maintenance costs by using galvanized steel strip. The zinc coating minimizes the need for frequent inspections and repairs. You spend less time and money on upkeep, allowing you to focus on other aspects of your project.

Economic Value

You maximize your investment with galvanized steel strip. Its durability and low maintenance requirements translate into long-term savings. You achieve economic value by choosing a material that performs reliably and lasts for years.

Tip: Selecting galvanized steel strip for your infrastructure projects helps you control costs and improve overall project efficiency.

Versatility and Sustainability

Application Range

You need materials that adapt to different environments and requirements. Galvanized steel strip gives you unmatched flexibility across industries. You use it in construction for roofing, furring channels, and steel pipes. You rely on it in the automotive sector for body components and cable armor. Utility installations benefit from its strength in water and gas pipelines, as well as electrical infrastructure.

You can select from a wide range of thicknesses and widths. This lets you match the product to your specific project needs. WITOP offers customization options, so you get the right hardness and spangle type for each application. You save time and resources when you choose a material that fits multiple uses.

Tip: When you work with a versatile product, you streamline your supply chain and simplify project management.

Environmental Impact

You care about sustainability in your projects. Galvanized steel strip supports your commitment to green building standards. You choose a product that is fully recyclable. After its service life, you can recover and reuse the steel, reducing waste and conserving resources.

You meet environmental regulations with confidence. WITOP’s manufacturing process minimizes emissions and uses advanced technology to reduce energy consumption. You contribute to a cleaner environment by selecting materials that align with eco-friendly practices.

- You lower your carbon footprint.

- You support circular economy principles.

- You help build a future where infrastructure and environmental responsibility go hand in hand.

Note: Sustainable choices today create lasting benefits for your business and the planet.

Applications in Big Builds

Construction Sector

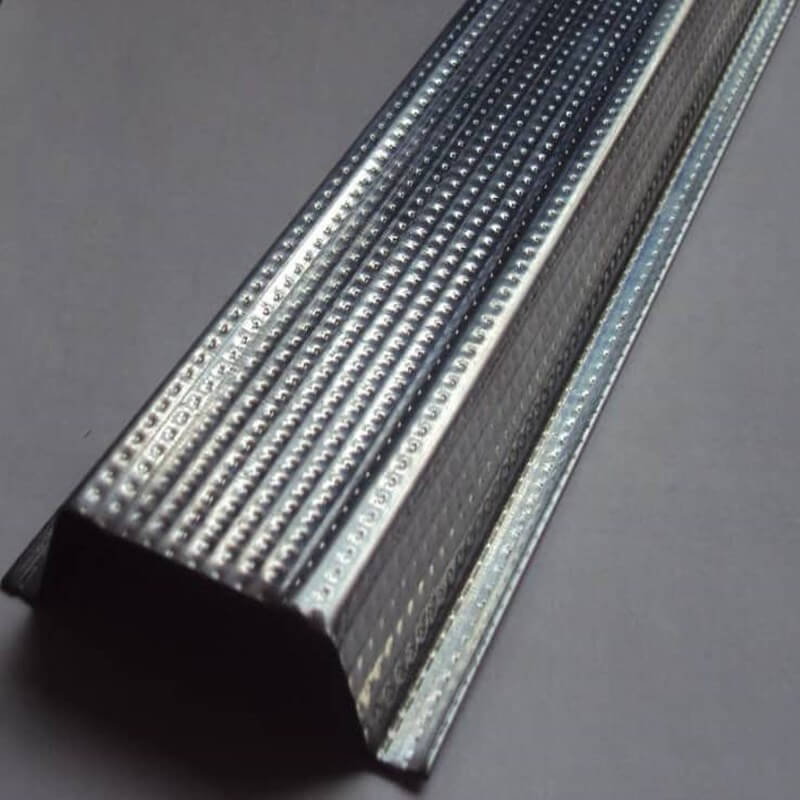

Roofing and Furring Channels

You need reliable materials for roofing and interior frameworks. Galvanized steel strip gives you the strength and corrosion resistance required for these demanding applications. When you install roofing panels, you want a product that stands up to rain, wind, and sun. The zinc coating on the steel strip protects your structures from rust and extends their service life. For furring channels, you benefit from a material that is easy to shape and install. You can create straight, stable lines for ceilings and walls, ensuring a professional finish every time.

Tip: Choose the right hardness level for your roofing or furring channel project. Softy works well for intricate bends, while full hard provides extra support for heavy loads.

Steel Pipes and Hoop Iron

You often use steel pipes and hoop iron in construction for support and reinforcement. Galvanized steel strip serves as the foundation for these products. You get pipes that resist corrosion, even when exposed to moisture or chemicals. Hoop iron, made from this steel strip, secures barrels, crates, and large packages. You can trust the material to maintain its shape and strength under pressure. This reliability helps you meet safety standards and deliver quality results on every job site.

Automotive Industry

Body Components

You demand materials that combine strength with formability in automotive manufacturing. Galvanized steel strip meets these needs for body components. You can stamp, cut, and weld the steel into doors, hoods, and frames. The zinc layer protects against rust, even in harsh weather or on salted winter roads. You deliver vehicles that look good and last longer, giving your customers confidence in your products.

Cable Armor

You protect electrical and communication cables with durable armor. Galvanized steel strip wraps around cables, shielding them from impact, moisture, and abrasion. You ensure that critical systems stay operational, even in tough environments. This protection is essential for vehicles, industrial equipment, and infrastructure projects.

Utility Installations

Water and Gas Pipelines

You rely on safe, long-lasting pipelines for water and gas distribution. Galvanized steel strip forms the backbone of these systems. The zinc coating prevents leaks caused by rust and corrosion. You reduce maintenance needs and extend the lifespan of your pipelines. This reliability supports public health and safety.

Electrical Infrastructure

You build electrical infrastructure that must withstand time and the elements. Galvanized steel strip provides the durability and conductivity needed for cable trays, conduits, and support brackets. You keep power flowing to homes, businesses, and industries. The material’s versatility allows you to adapt to different installation requirements, making your projects more efficient.

Note: When you choose galvanized steel strip for these applications, you invest in quality, safety, and long-term performance.

witop Project Highlights

Industry Solutions

You face unique challenges in every industry. WITOP’s galvanized steel strip gives you solutions that meet strict standards and demanding environments. You can rely on WITOP’s expertise to deliver products that fit your project’s needs. The company offers a wide range of thicknesses, widths, hardness levels, and spangle types. You select the right combination for your application, whether you work in construction, automotive, or utilities.

You benefit from WITOP’s advanced manufacturing process. The continuous hot-dip galvanizing method ensures a consistent zinc coating. You get steel strips that resist corrosion and maintain strength under pressure. WITOP’s quality control team tests every batch. You receive materials that pass rigorous inspections and certifications.

WITOP supports your goals for sustainability. You choose steel strips that are recyclable and meet green building standards. The company uses energy-efficient production methods. You help reduce your project’s environmental impact.

Tip: You can contact WITOP’s technical support team for guidance on selecting the best steel strip for your project. Their experts help you match specifications to your requirements.

Real-World Examples

You see the impact of WITOP’s galvanized steel strip in major projects around the world. The following examples show how you can use these products to solve real challenges:

| Project Type | Application | Benefit to You |

|---|---|---|

| Bridge Construction | Support beams, guardrails | Extended lifespan, safety |

| Highway Installations | Signposts, barriers | Rust resistance, reliability |

| Commercial Buildings | Roofing, wall panels | Low maintenance, durability |

| Utility Networks | Water/gas pipelines | Leak prevention, longevity |

| Automotive Plants | Body components, cable armor | Formability, corrosion protection |

You can learn from these successful projects. For example, you might use WITOP’s full hard galvanized steel strip for bridge guardrails. You ensure the structure withstands heavy traffic and harsh weather. In commercial buildings, you select small spangle strips for decorative wall panels. You achieve a clean look and long-lasting performance.

Note: WITOP’s case studies show how you can improve safety, reduce costs, and meet environmental goals with the right steel strip.

You gain confidence when you choose WITOP for your big builds. The company’s proven solutions and real-world results help you deliver projects that stand the test of time.

Choosing Galvanized Steel Strip

Quality Standards

Testing and Certification

You want to ensure that every steel strip you use meets the highest standards. Look for products that undergo strict testing and hold recognized certifications. Reliable suppliers, like WITOP, use advanced equipment to check for coating thickness, mechanical strength, and surface finish. You can trust that each batch meets industry requirements for safety and performance. Certified products give you peace of mind and help you comply with project specifications.

witop Quality Control

You benefit from WITOP’s commitment to quality at every stage. Their professional team inspects raw materials, monitors the galvanizing process, and checks the final product before shipping. You receive steel strips that pass rigorous quality control, ensuring consistent results for your builds. WITOP’s attention to detail means you avoid unexpected issues on site and deliver projects that stand the test of time.

Tip: Always ask your supplier about their quality control process. Consistent testing helps you avoid costly delays and rework.

Specification Selection

Thickness and Width

You need steel strips that fit your project’s exact needs. Consider the thickness and width required for your application. WITOP offers a wide range, from 0.11 mm to 4.00 mm in thickness and 20 mm to 599 mm in width. You select the right dimensions for roofing, pipes, or structural supports. Choosing the correct size ensures your materials perform as expected and integrate smoothly into your designs.

Coating and Spangle Choice

You also decide on the zinc coating thickness and spangle type. Thicker coatings provide extra protection in harsh environments. Spangle types—such as zero, small, regular, or big—affect both appearance and performance. For visible surfaces, you might prefer a smooth, matte finish. For industrial uses, a larger spangle may suit your needs. WITOP’s customization options let you match the steel strip to your project’s technical and aesthetic requirements.

Note: Matching the right coating and spangle to your environment helps you maximize durability and visual appeal.

Supplier Evaluation

Reliability

You depend on your supplier’s reliability to keep your project on track. Choose a partner with a proven track record and strong customer support. WITOP delivers consistent quality and on-time shipments, so you avoid costly interruptions. Their experience in large-scale projects means you get expert advice and dependable service.

Support Services

You gain more value when your supplier offers a full range of support services. Leading suppliers provide precision cutting, bending, straightening, and advanced machining. Some also offer oxy-fuel and laser cutting for specialized needs. These services help you save time and reduce waste by delivering steel strips ready for installation.

| Service Type | Description |

|---|---|

| Cutting | Precision cutting of galvanized steel strips to required dimensions. |

| Bending | Shaping strips into desired angles or curves. |

| Straightening | Correcting any warping or bending in the strips. |

| Oxy-fuel cutting | Using oxy-fuel techniques for cutting thicker materials. |

| Machining | Additional machining processes for specific applications. |

| Laser cutting | High-precision cutting using laser technology. |

Tip: Ask your supplier about available processing services. Customization at the source streamlines your workflow and improves project efficiency.

You make better decisions when you focus on quality, specifications, and supplier support. With WITOP, you get a partner dedicated to your project’s success.

Success Stories

Bridge Projects

Durability Impact

You face demanding conditions when you build bridges. Galvanized steel strip gives you the durability you need for long-lasting structures. The zinc coating protects steel beams and guardrails from moisture and harsh weather. You see bridges that stand strong year after year, even in coastal regions or areas with heavy rainfall. You avoid frequent repairs because the steel resists rust and corrosion. When you choose galvanized steel strip, you invest in infrastructure that supports communities and withstands the test of time.

Tip: You can extend the lifespan of bridge components by selecting full hard galvanized steel strip for maximum strength and protection.

Highway Installations

Safety and Longevity

You want highways to remain safe and reliable for drivers. Galvanized steel strip plays a key role in highway installations. You use it for signposts, guardrails, and safety barriers. The zinc layer shields these structures from road salt, rain, and temperature changes. You reduce the risk of accidents because the steel maintains its integrity and visibility. You also lower maintenance costs since the material does not require frequent replacement. Highways built with galvanized steel strip offer you peace of mind and long-term value.

| Application | Benefit to You |

|---|---|

| Guardrails | Enhanced safety |

| Signposts | Long-lasting visibility |

| Safety barriers | Reduced maintenance |

Note: You improve public safety and save resources when you choose galvanized steel strip for highway projects.

Building Applications

Cost and Performance

You look for materials that balance cost and performance in building projects. Galvanized steel strip meets your needs by offering excellent value and reliability. You use it in many areas of construction:

- Electrical installations

- Ventilation systems

- Light structural components

- Metal structures

- General construction projects

You benefit from lower maintenance costs because the steel resists corrosion and structural failures. You avoid unexpected expenses and keep your buildings safe for occupants. Galvanized steel strip helps you meet project budgets without sacrificing quality. You see long-term savings and consistent performance, making it a smart choice for both small and large builds.

Block Quote: “Galvanized steel strip is recognized for its cost-effectiveness, as it reduces maintenance costs and prevents structural failures. This makes it an economical choice, especially for long-term projects, ensuring both durability and performance.”

You deliver buildings that last, using materials that support your reputation for quality and efficiency.

witop in Action

Case Highlights

You want to see how WITOP’s galvanized steel strip performs in real-world projects. These case highlights show you the difference that quality materials and expert support can make. Each example demonstrates how you can solve challenges and achieve outstanding results with WITOP by your side.

1. Coastal Bridge Reinforcement

You face harsh marine environments when you build bridges near the sea. Saltwater and humidity threaten to corrode ordinary steel. WITOP supplied full hard galvanized steel strip for a major coastal bridge project. The zinc coating protected the beams and guardrails from rust. You saw the bridge maintain its strength and appearance, even after years of exposure. The project team reported minimal maintenance and no structural failures.

2. Urban Highway Safety Upgrade

You need reliable materials for highway safety barriers and signposts. In a busy metropolitan area, WITOP delivered semi-hard galvanized steel strip for new guardrails and road signage. The steel resisted corrosion from rain and road salt. You noticed that the barriers stayed strong and visible, reducing the risk of accidents. The city saved on repair costs and improved public safety.

3. Commercial Building Modernization

You want your buildings to look good and last long. A commercial developer chose WITOP’s small spangle galvanized steel strip for decorative wall panels and roofing. The smooth finish gave the building a modern look. The zinc layer prevented rust, even in areas with high humidity. The developer praised the easy installation and long-term durability.

4. Utility Pipeline Reliability

You rely on safe water and gas delivery. A utility company selected WITOP’s galvanized steel strip for new pipelines. The zinc coating stopped leaks caused by corrosion. The pipelines performed well under pressure and required less maintenance. The company met strict safety standards and delivered reliable service to customers.

Note: You can contact WITOP’s technical team for advice on choosing the right steel strip for your project. Their experts help you match product specifications to your unique needs.

| Project Type | WITOP Solution | Key Benefit |

|---|---|---|

| Coastal Bridge | Full Hard, Thick Coating | Corrosion resistance |

| Urban Highway | Semi-Hard, Regular Spangle | Safety, low maintenance |

| Commercial Building | Small Spangle, Custom Width | Aesthetics, durability |

| Utility Pipeline | Softy, Thick Coating | Leak prevention, longevity |

You see that WITOP’s galvanized steel strip adapts to your toughest challenges. You get materials that meet strict standards and deliver proven results. When you choose WITOP, you invest in quality, safety, and long-term value for every big build.

You secure lasting value for your projects when you choose galvanized steel strip. Its proven resistance and longevity mean you need maintenance only after decades, even in tough environments. WITOP’s strict quality control ensures you receive a homogeneous, reliable material.

- Galvanization boosts durability and safety.

- Market trends show rising steel prices, making smart choices essential.

| Method | Benefits | Material |

|---|---|---|

| Light Steel Frame | Sustainability, speed, waste reduction | Galvanized steel |

You elevate every big build with materials that deliver strength, versatility, and economic value.

FAQ

What is galvanized steel strip used for?

You use galvanized steel strip in construction, automotive, and utility projects. It works well for roofing, pipes, cable armor, and structural supports. You benefit from its durability and corrosion resistance.

How does the zinc coating protect steel?

You get a protective barrier with the zinc coating. It stops moisture and oxygen from reaching the steel. This prevents rust and extends the life of your materials.

Can you customize the hardness and spangle type?

You select from Softy, Semi-Hard, or Full Hard options. You also choose spangle types like zero, small, regular, or big. WITOP tailors products to your project needs.

What thickness and width options are available?

You choose thicknesses from 0.11 mm to 4.00 mm. Widths range from 20 mm to 599 mm. This flexibility lets you match the steel strip to your application.

Is galvanized steel strip environmentally friendly?

You support sustainability when you use galvanized steel strip. It is fully recyclable. WITOP’s manufacturing process reduces emissions and energy use.

How do you ensure product quality?

You rely on WITOP’s advanced testing and strict quality control. Their team inspects every batch for coating thickness, strength, and finish. You receive certified, reliable materials.

What industries benefit most from galvanized steel strip?

You see advantages in construction, automotive, utilities, and manufacturing. The material’s strength and corrosion resistance make it a preferred choice for demanding environments.

How do you order or get technical support?

You contact WITOP’s technical team for guidance. They help you select specifications and answer your questions. You get expert support throughout your project.