You should choose matte PPGI steel for projects that demand both extended durability and a refined, modern appearance. This coil delivers consistent color, a layered matte texture, and reduces maintenance due to its advanced protective coating.

- You achieve aesthetic uniformity on roofing and facades.

- You benefit from a finish that lasts longer and resists corrosion better than standard options.

Consider your priorities—design, lifespan, and maintenance—when selecting the right steel coil for your application.

Key Takeaways

- Choose matte PPGI steel for projects needing durability and a modern look.

- Matte PPGI steel offers a longer service life, lasting up to 1.5 times longer than standard options.

- The advanced protective coating on matte PPGI steel reduces maintenance and corrosion.

- Select matte PPGI steel for high-end architectural projects and visible facades.

- Standard PPGI steel is ideal for cost-effective, traditional applications like warehouses and barns.

- Consider your project’s goals, design vision, and expected lifespan when choosing steel.

- Matte finishes create a sophisticated atmosphere, while glossy finishes provide a classic look.

- Consult with experts to ensure you select the right steel coil for your specific needs.

Matte vs Standard PPGI Steel Overview

Key Features Compared

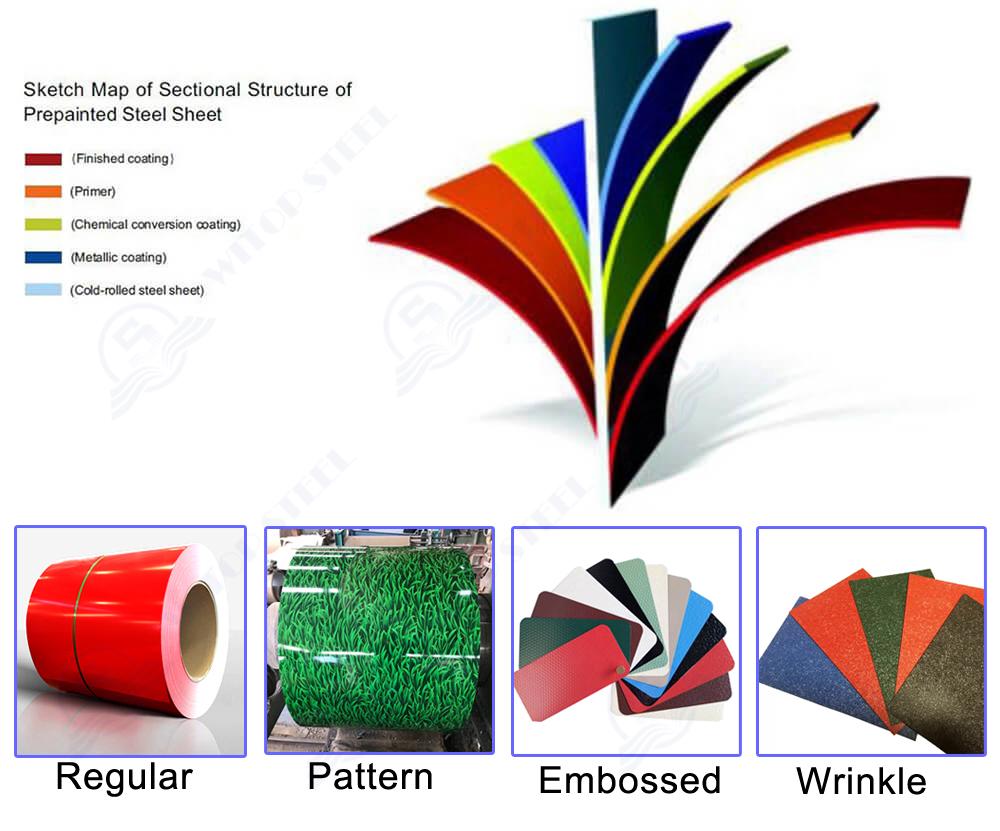

You need to understand the core differences between matte PPGI steel and standard PPGI steel before making a decision. The table below highlights the main features that set these two products apart:

| Feature | Matte PPGI Steel Coil | Standard PPGI Steel Coil |

|---|---|---|

| Surface Finish | Matte, non-reflective, layered texture | Glossy, smooth, reflective |

| Durability | Service life up to 1.5x longer | Standard service life |

| Corrosion Resistance | Enhanced with high zinc coating | Good, but less advanced |

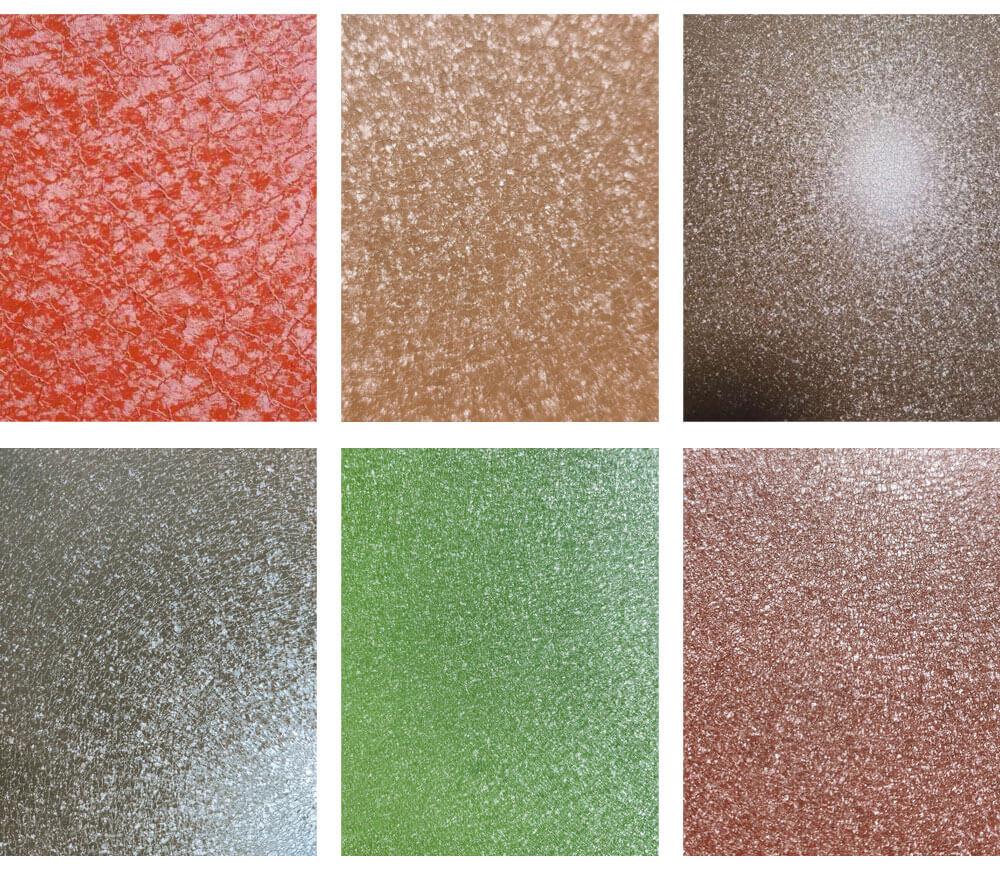

| Color Range | Wide (RAL/custom colors available) | Standard palette |

| Design Appeal | Modern, premium, architectural | Traditional, general purpose |

| Applications | High-end construction, appliances, furniture | Roofing, siding, industrial, agricultural |

Tip: If your project requires a modern look and long-term performance, you should prioritize matte PPGI steel.

Best Uses Summary

You should match the steel coil type to your project’s unique requirements. Matte PPGI steel works best for high-end architectural projects, visible building facades, and designer applications. You can use it for roofing, wall panels, and exterior elements where aesthetics and durability matter most. It also fits well in the production of appliances and furniture that demand a refined finish.

Standard PPGI steel suits projects where cost efficiency and traditional appearance take priority. You can rely on it for industrial buildings, agricultural structures, and general roofing or siding. It provides reliable protection and a classic look for less demanding environments.

- Choose matte PPGI steel if you want:

- A sophisticated, non-glossy finish

- Extended service life and superior corrosion resistance

- Custom color options for unique designs

- Enhanced value for high-profile projects

- Choose standard PPGI steel if you need:

- A cost-effective solution for large-scale or utilitarian projects

- A traditional, glossy appearance

- Reliable performance for general construction

You should always evaluate your project’s goals, design vision, and expected lifespan before making your final selection.

Appearance and Design

Matte Finish Look

Texture and Color Range

You notice the difference in texture as soon as you see matte PPGI steel. The surface feels layered and rich, not flat or plain. This finish hides small imperfections and creates a uniform look across large surfaces. You can select from a wide range of colors, including any RAL shade or custom sample. This flexibility allows you to match your project’s color palette exactly. The matte surface does not reflect light harshly, so you achieve a soft, elegant effect that works well in both exterior and interior applications.

Modern Design Appeal

You want your project to stand out. Matte PPGI steel helps you achieve a modern, sophisticated appearance. The non-reflective finish creates a subtle and cozy atmosphere, especially in spaces where you want to avoid glare. Many architects and designers choose matte finishes for bedrooms, living rooms, and facades because these areas benefit from a calm, understated look. When you use luxury finishes, you send a clear message: you value quality and excellence in your environment. A well-finished element, such as a door or panel, can elevate the perception of your entire project.

Note: Matte finishes do more than look good—they reinforce the value of high-quality design and attention to detail.

Standard Finish Look

Gloss and Reflectivity

You see a glossy, smooth surface when you choose standard PPGI steel. This finish reflects light and creates a bright, traditional appearance. The gloss can highlight the shape and lines of your building or product. You often find this finish in industrial and agricultural settings, where a classic look is preferred.

Traditional Uses

You rely on standard finishes for projects that require a familiar style. These finishes suit warehouses, barns, and general-purpose buildings. The reflective surface gives a sense of cleanliness and order, which works well in functional environments.

Design Impact

Matching Project Style

You need to match the finish to your project’s style. Matte PPGI steel provides an opaque look that hides imperfections and creates a subtle, inviting atmosphere. This makes it ideal for modern architecture and spaces designed for relaxation. Standard finishes, with their gloss and shine, fit best in traditional or utilitarian projects.

- Matte finish: Subtle, cozy, modern

- Gloss finish: Bright, classic, functional

Perceived Value

You influence how people perceive your project through your choice of finish. When you select matte PPGI steel, you show a commitment to quality and design excellence. Luxury finishes are not just about appearance—they make a statement about your standards. A well-finished surface can elevate the entire project, making it feel more valuable and refined.

Choosing the right finish impacts not only the look but also the perceived value of your work.

Matte PPGI Steel Performance

Durability and Service Life

Anti-Corrosion Properties

You want your project to last. Matte PPGI steel gives you advanced protection against corrosion. The steel receives a zinc layer during manufacturing. This layer acts as a barrier and provides cathodic protection. You can rely on this feature for outdoor applications such as roofs and gutters. The zinc coating shields the steel from moisture and harsh weather. You also benefit from a high-quality paint film. The paint adds another layer of defense and keeps the surface looking fresh. You see less rust and fewer signs of wear over time.

- Zinc coating ranges from 40 to 275 g/m².

- Paint film creates a consistent and attractive finish.

- Both layers work together to prevent corrosion.

You reduce maintenance costs and extend the life of your project when you choose matte PPGI steel.

Longevity vs Standard

You notice a clear difference in service life. Matte PPGI steel lasts about 1.5 times longer than standard PPGI steel. The combination of zinc and paint gives you a product that stands up to tough environments. You can use it for exterior walls, roofing, and panels that face sun, rain, and wind. The finish does not fade quickly. You get a surface that stays strong and beautiful for years. Standard PPGI steel performs well, but matte PPGI steel sets a higher standard for durability.

Quality Standards

International Certifications

You want to trust the materials you use. Matte PPGI steel meets strict international standards. You see certifications such as JIS G 3312, EN 10169, and ASTM A755. These standards guarantee quality and consistency. You can specify these certifications in your project documents. You know the steel will perform as promised.

International certifications give you confidence in every coil you order.

Manufacturing Range

You have flexibility when you choose matte PPGI steel. The product comes in thicknesses from 0.10 to 3.00 mm and widths from 20 to 1250 mm. You can select the right size for your application. The wide range of options lets you match your design needs. You also get a choice of colors, including any RAL shade or custom sample. The manufacturing process ensures each coil meets high standards for strength and appearance.

- Thickness: 0.10–3.00 mm

- Width: 20–1250 mm

- Zinc coating: 40–275 g/m²

- Color: RAL or custom

You achieve both technical performance and design flexibility with matte PPGI steel.

Cost and Value

Price Comparison

Factors Affecting Cost

You need to look beyond the price per ton when comparing matte PPGI steel coil and standard PPGI steel coil. The total cost for your project depends on several important factors:

- Lifespan: Matte PPGI steel lasts longer, which means you replace it less often.

- Maintenance and Repainting: You spend less on repainting and repairs with matte PPGI steel because its finish resists corrosion and fading.

- Cutting Losses: You experience fewer losses during cutting and installation due to the coil’s consistent quality.

- Productivity: You save time and resources in the installation process since matte PPGI steel often requires fewer steps.

- Waste Reduction: You minimize waste because the coil’s durability reduces the need for replacements.

You should calculate the cost per final installed piece, not just the initial material cost. This approach gives you a clearer picture of your project’s true expenses.

Market Trends

You see a growing demand for matte PPGI steel in architectural and high-end construction markets. Many designers and builders prefer matte finishes for their modern look and extended service life. As more projects require premium materials, the price gap between matte and standard PPGI steel narrows. You notice that investing in advanced coatings and finishes has become a trend, especially for projects that value aesthetics and longevity. Market data shows that clients are willing to pay more for materials that reduce long-term costs and maintenance.

You benefit from following market trends that prioritize durability and design, especially if you want your project to stand out.

Value for Money

Long-Term Savings

You achieve significant savings over the life of your project when you choose matte PPGI steel. The coil’s superior anti-corrosion properties and longer service life mean you spend less on maintenance and replacements. You avoid frequent repainting, which saves both time and money. When you factor in reduced cutting losses and lower waste, the total cost of ownership drops. You invest more upfront, but you recover these costs through fewer repairs and longer intervals between replacements.

Investment for High-End Projects

You make a smart investment when you select matte PPGI steel for high-profile or luxury projects. The finish elevates the perceived value of your building or product. You impress clients and stakeholders with a surface that stays beautiful and strong for years. You also meet international quality standards, which adds credibility to your work. For projects where appearance and durability matter most, matte PPGI steel delivers a return on investment that standard coils cannot match.

You maximize your project’s value by choosing materials that combine performance, aesthetics, and long-term savings.

Applications

Matte PPGI Steel Uses

Construction and Architecture

You can use matte PPGI steel in many high-end construction projects. Architects often select this material for modern building facades, roofing systems, and wall panels. The matte finish creates a sophisticated look that stands out in urban environments. You see it on luxury residential buildings, commercial complexes, and public spaces. The advanced anti-corrosion coating ensures that roofs and exterior panels maintain their appearance for years. You can also specify this steel for decorative elements, such as fences, gates, and exterior cladding. The wide color range allows you to match any design vision.

Appliances and Furniture

You find matte PPGI steel in the production of home appliances and furniture. Manufacturers use it for refrigerator doors, washing machine panels, and kitchen cabinetry. The matte surface resists fingerprints and scratches, making it ideal for high-touch areas. You can also see this material in office furniture, shelving, and storage units. Designers appreciate the uniform color and texture, which help create a premium look in both residential and commercial interiors.

Standard PPGI Steel Uses

Industrial and Agricultural

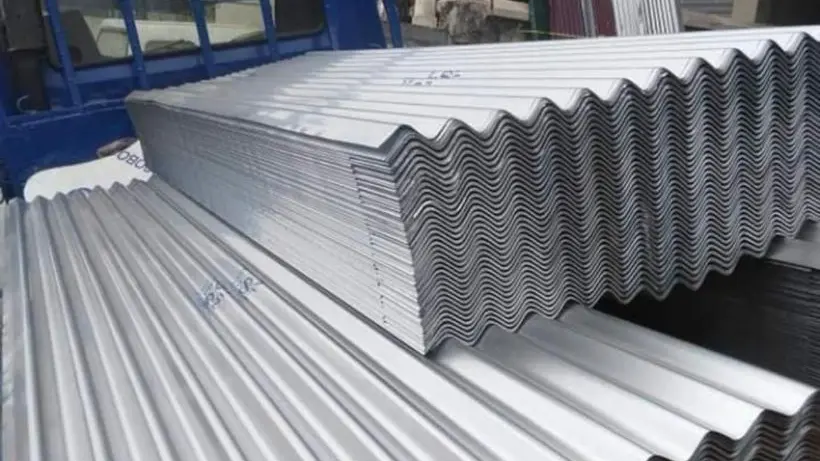

You often choose standard PPGI steel for industrial and agricultural buildings. This material works well for warehouses, barns, and storage sheds. The glossy finish provides a clean, traditional appearance. You can use it for roofing, siding, and partition walls in large-scale facilities. Farmers rely on standard PPGI steel for equipment shelters and animal housing. The material offers reliable protection in demanding environments.

General Purpose

You see standard PPGI steel in many general-purpose applications. Builders use it for rolling shutter doors, container walls, and simple fencing. The material suits projects where cost efficiency and basic performance matter most. You can install it quickly and maintain it with minimal effort. Standard PPGI steel remains a popular choice for projects that do not require advanced finishes or custom colors.

Real-World Examples

Project Case Studies

You can look at several real-world projects to understand the benefits of each type. A luxury apartment complex in a major city used matte PPGI steel for its facade and roofing. The result was a modern, elegant appearance that attracted high-end buyers. The building’s exterior has maintained its color and finish despite exposure to harsh weather.

In another example, a large agricultural facility chose standard PPGI steel for its barns and storage units. The project team valued the material’s cost-effectiveness and ease of installation. The glossy finish provided a clean look that suited the rural setting.

Tip: When you select the right steel coil for your project, you ensure both performance and visual appeal. Review similar case studies to guide your decision.

Choosing the Right PPGI Steel

Decision Guide

Project Priorities

You should start by identifying your main project goals. Ask yourself what matters most. Do you want a modern look that impresses clients? Do you need a material that lasts for decades with little maintenance? If you value aesthetics and long-term performance, matte PPGI steel will serve you best. For projects where function and cost take priority, standard PPGI steel may fit your needs.

Tip: Write down your top three project priorities before you compare materials.

Environmental Factors

You must consider the environment where you will use the steel. Humid climates, coastal areas, and regions with heavy rainfall can speed up corrosion. Matte PPGI steel offers advanced anti-corrosion protection, making it a smart choice for harsh environments. If your project sits in a mild climate or indoors, standard PPGI steel can provide reliable service.

- For outdoor or coastal projects: Choose matte PPGI steel.

- For indoor or low-risk areas: Standard PPGI steel may suffice.

Budget and Aesthetics

You need to balance your budget with your design vision. Matte PPGI steel costs more upfront, but you save money over time due to fewer repairs and less repainting. If your project demands a premium look, the matte finish delivers a high-end appearance. For basic projects with tight budgets, standard PPGI steel remains a practical option.

| Factor | Matte PPGI Steel | Standard PPGI Steel |

|---|---|---|

| Upfront Cost | Higher | Lower |

| Maintenance | Minimal | Moderate |

| Design Impact | Premium | Traditional |

Selection Checklist

Key Questions

You should ask yourself these questions before you decide:

- What is the expected lifespan of my project?

- Will the steel face harsh weather or chemicals?

- How important is the appearance to my client or end user?

- Do I need custom colors or a specific finish?

- What is my total budget, including maintenance?

Note: Honest answers will help you choose the right steel coil.

Consulting Experts

You should consult with suppliers or technical experts if you feel unsure. They can review your project details and recommend the best coil type. Bring your checklist and project drawings to the meeting. Ask for product samples and certifications. You gain peace of mind when you make an informed decision with expert support.

Remember: The right choice today leads to fewer problems tomorrow.

You now understand the key differences between matte PPGI steel and standard PPGI steel. Choose the coil that matches your project’s durability and design needs. Review your checklist before making a decision. Consult suppliers for expert advice. Consider long-term value and specific application requirements to ensure the best results.

- Match coil type to your project goals

- Use expert guidance for tailored solutions

- Focus on durability and design impact

Smart choices today lead to lasting project success.

FAQ

What is the main advantage of matte PPGI steel over standard PPGI steel?

You gain a longer service life and a modern, non-reflective finish with matte PPGI steel. The advanced coating resists corrosion better, making it ideal for high-end projects.

Can you use matte PPGI steel for exterior applications?

Yes, you can. Matte PPGI steel works well for roofing, facades, and exterior panels. The zinc coating and paint film protect against harsh weather and UV exposure.

How do you choose the right color for your project?

You select from a wide range of RAL colors or request a custom sample. This flexibility lets you match your project’s branding or design vision exactly.

Does matte PPGI steel require special maintenance?

You spend less time on maintenance with matte PPGI steel. The durable finish resists fading and corrosion, so you clean it with mild soap and water as needed.

Is matte PPGI steel suitable for appliances and furniture?

Absolutely! You can use matte PPGI steel for appliance panels, cabinets, and furniture. The surface hides fingerprints and scratches, keeping products looking new.

What certifications should you look for when buying PPGI steel?

You should check for international standards like JIS G 3312, EN 10169, or ASTM A755. These certifications ensure you receive consistent quality and performance.

How does the cost of matte PPGI steel compare to standard PPGI steel?

You pay more upfront for matte PPGI steel, but you save money over time. The longer service life and reduced maintenance lower your total project costs.