You see matt galvalume coil used more in modern construction because it brings you a blend of style and strength. This material stands out with its matte finish, giving surfaces a modern look while also adding slip resistance. You get a product that resists corrosion, handles heat well, and keeps its shape. Matt galvalume coil offers you flexibility for shaping and cutting, so you can use it in many ways. You also benefit from its durability, which lowers your maintenance costs. Matt galvalume coil supports sustainability since you can recycle it. When you choose matt galvalume coil, you improve both the performance and the appearance of your project.

Key Takeaways

- Matt galvalume coil combines style and strength, making it ideal for modern construction projects.

- The aluminum-zinc coating provides excellent corrosion resistance, extending the lifespan of the material.

- Galvalume is three to four times more durable than traditional galvanized steel, reducing maintenance costs.

- The matte finish not only enhances aesthetics but also adds slip resistance, making it safe for various applications.

- Galvalume is fully recyclable, supporting sustainability and reducing environmental impact.

- Choose the right grade and thickness for your project to ensure optimal performance and safety.

- Regular inspections and cleaning help maintain the coil’s appearance and prevent rust.

- Work with certified suppliers to ensure quality and compliance with industry standards.

What Is Matt Galvalume Coil?

Composition and Structure

When you look at a galvalume steel coil, you see more than just a metal sheet. This material uses a special aluminum zinc alloy to protect the steel. The coating contains three main elements. You can see their exact percentages in the table below:

| Element | Percentage |

|---|---|

| Aluminum | 55% |

| Zinc | 43.4% |

| Silicon | 1.6% |

This unique blend gives galvalume its strength and resistance to rust. The aluminum zinc alloy forms a barrier that shields the steel from moisture and chemicals. Silicon helps the coating stick tightly to the steel, making the galvalume steel coil even more reliable.

Manufacturing Process

You get a galvalume steel coil through a careful process that starts with raw materials and ends with a finished product ready for construction. Here are the main steps:

- Steel mills heat iron ore and other materials to create molten iron, called pig iron.

- Workers add new elements to the pig iron, then cool and shape it into plates.

- The plates go through rolling, which turns them into thin sheets. This can be done hot or cold.

- For galvalume, the steel sheets are cold-rolled. After rolling, the sheets receive a coating of aluminum zinc alloy, which sets galvalume apart from other types of steel.

This process ensures that every galvalume steel coil has a strong, even coating. You get a product that stands up to tough conditions and lasts for years.

Key Properties

Galvalume steel coil stands out because of its physical and chemical properties. You can see some of the most important features in the table below:

| Property | Description |

|---|---|

| Corrosion Resistance | Galvalume combines aluminum’s corrosion resistance with zinc’s sacrificial protection, extending lifespan significantly. |

| Durability | It lasts two to four times longer than traditional galvanized steel, making it ideal for construction. |

| Coating Composition | The protective alloy consists of 55% aluminum, 43.4% zinc, and 1.6% silicon, enhancing its protective qualities. |

You benefit from a galvalume steel coil that resists rust, handles harsh weather, and keeps its appearance over time. The matte finish adds slip resistance and a modern look. You can use galvalume in many places, from roofing to wall panels. The aluminum zinc alloy coating makes it a smart choice for projects that need both style and strength.

Tip: When you choose galvalume steel coil, you invest in a material that offers long-term value and performance for your construction needs.

Benefits of Matt Galvalume Coil

Corrosion Resistance

You want your construction materials to last, especially in harsh environments. Galvalume stands out because of its excellent corrosion resistance. The special aluminum-zinc coating on galvalume steel coil forms a strong barrier. This layer protects the steel from moisture, chemicals, and salt in the air. You see the benefits most in humid or marine locations, where rust can destroy ordinary steel.

The matte finish on galvalume adds another layer of protection. It helps prevent scratches and keeps the surface looking new. You can trust galvalume steel coil to resist rust and wear, even after years of use. The protective layer works hard to stop corrosion before it starts. You get peace of mind knowing your project will stay strong and attractive.

- The protective layer prevents wear over time, especially in humid or marine environments.

- Galvalume steel coil offers corrosion resistance that lasts for decades.

- You need less maintenance because the material resists rust and stains.

Tip: Choose galvalume for projects that face tough weather or high humidity. You will see fewer repairs and longer service life.

Durability and Longevity

When you use galvalume steel coil, you invest in a material built for the long haul. Galvalume is three to four times more resistant than galvanized steel. This means you get a much higher life expectancy for your buildings and products. The combination of aluminum and zinc in the coating gives galvalume its strength.

You can use galvalume in both indoor and outdoor settings. It stands up to rain, sun, and temperature changes. You do not have to worry about frequent replacements. The high durability of galvalume steel coil means you save money on repairs and maintenance.

Here is a quick look at why galvalume lasts so long:

| Feature | Benefit |

|---|---|

| Aluminum-zinc coating | Shields steel from rust and corrosion |

| Matte finish | Reduces scratches and surface damage |

| High durability | Extends life expectancy in all environments |

| Low maintenance | Keeps costs down over the years |

You can expect a long life expectancy for galvalume steel coil in both indoor and outdoor projects. The material keeps its shape and strength, even after years of exposure.

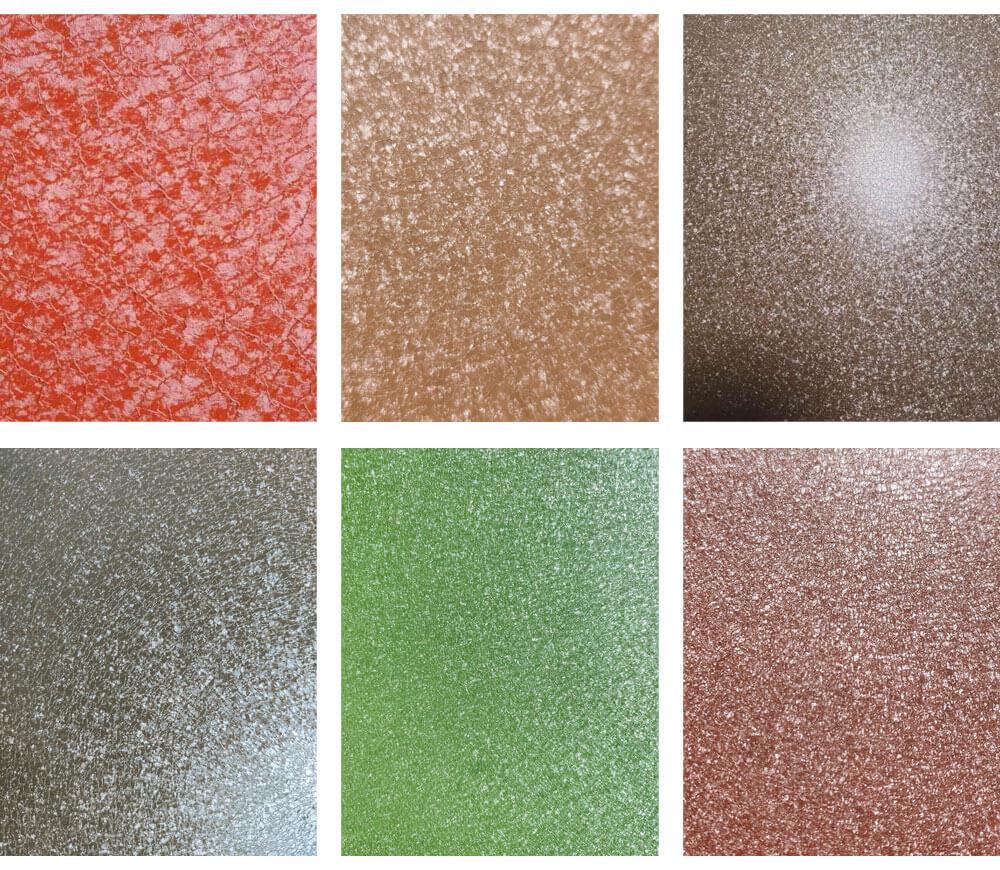

Aesthetic and Texture

You want your project to look good as well as perform well. Galvalume gives you both. The matte finish on galvalume steel coil creates a modern, stylish appearance. It does not reflect too much light, so you get a soft, elegant look. This finish also hides fingerprints and minor marks, keeping surfaces clean.

The texture of galvalume adds slip resistance. You can use it for roofing, wall panels, or decorative features. The surface feels pleasant to the touch and looks great in any setting. You can choose from a wide range of colors to match your design.

- Matte finish provides a unique, contemporary look.

- Slip resistance makes galvalume safe for floors and roofs.

- Custom color options let you match any style.

Galvalume steel coil helps you create buildings and products that stand out. You get durability, corrosion resistance, and a beautiful finish all in one material.

Cost-Effectiveness

You want your construction project to stay within budget. Galvalume helps you achieve this goal. When you choose galvalume steel coil, you invest in a material that saves you money over time. The initial price may seem similar to other steel products, but the long-term savings set galvalume apart.

Galvalume lasts much longer than regular steel. You do not need to replace it as often. This means you spend less on repairs and maintenance. The protective coating on galvalume steel coil reduces the risk of rust and surface damage. You avoid costly downtime and unexpected expenses.

Here are some ways galvalume helps you control costs:

- Fewer replacements: Galvalume steel coil can last twice as long as standard PPGL steel coils.

- Lower maintenance: The strong coating resists scratches and stains, so you do not need frequent touch-ups.

- Less waste: You use fewer materials over the life of your project.

- Energy savings: Galvalume reflects sunlight, which can help keep buildings cooler and reduce air conditioning costs.

Note: Galvalume gives you value for your money. You get a product that performs well and keeps your project affordable.

You can see the cost benefits in the table below:

| Feature | Cost Advantage |

|---|---|

| Long service life | Reduces replacement costs |

| Low maintenance needs | Cuts repair and upkeep expenses |

| High durability | Prevents early failures |

| Reflective surface | Lowers energy bills |

When you use galvalume steel coil, you make a smart investment. You protect your budget and your building at the same time.

Environmental Impact

You care about the environment and want to make responsible choices. Galvalume supports your sustainability goals. The production process for galvalume uses fewer resources than many other metals. You help reduce waste and energy use when you select galvalume steel coil for your project.

Galvalume is fully recyclable. When a building reaches the end of its life, you can recycle the galvalume steel coil instead of sending it to a landfill. This keeps valuable materials in use and lowers the demand for new raw materials.

Here are some environmental benefits of galvalume:

- Recyclable: You can recycle galvalume steel coil without losing quality.

- Energy efficient: The reflective surface helps reduce cooling needs in buildings.

- Long lifespan: You use fewer resources because you do not need to replace galvalume as often.

- Lower emissions: The durable coating means less frequent manufacturing and transportation.

Tip: Choosing galvalume helps you meet green building standards and supports a healthier planet.

You make a positive impact when you use galvalume steel coil. You save money, protect your project, and support the environment all at once.

Applications of Matt Galvalume Coil

You can find matt galvalume coil in many industries because of its versatility and strength. This material works well for both indoor and outdoor projects. You see it used in building and construction, furniture, decorative elements, and even in appliances. The matte finish and slip resistance make it a smart choice for surfaces that need both style and safety.

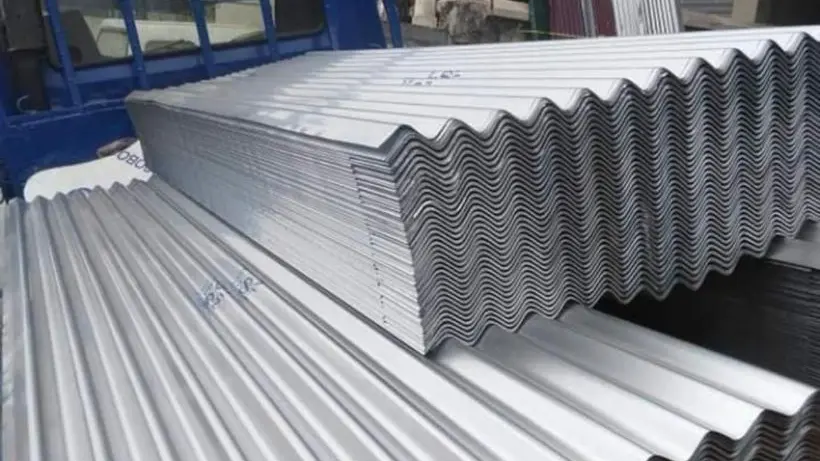

Construction Uses

Matt galvalume coil plays a key role in modern construction. You can use it for roofs, panels, and gutters. The material stands up to harsh weather and keeps its appearance for years. The table below shows some common uses in construction:

| Application Type | Description |

|---|---|

| Roofs | Ideal for roofing due to high corrosion resistance. |

| Panels | Used in various panel applications for durability. |

| Gutters | Effective for gutters exposed to weather conditions. |

Roofing and Cladding

You often see galvalume used for roofing and cladding. The aluminum-zinc coating protects the steel from rain, sun, and wind. The matte finish reduces glare, which helps in bright environments. You get a roof that lasts longer and needs less maintenance. Builders choose galvalume steel coil for both residential and commercial roofs. The material also works well for wall cladding, giving buildings a modern look and extra protection.

Sandwich Panels

You can use matt galvalume coil to make sandwich panels. These panels have layers that include insulation between two sheets of steel. The galvalume surface keeps the panel strong and resists rust. You find sandwich panels in warehouses, factories, and cold storage buildings. They help control temperature and add strength to walls and roofs.

Rolling Shutter Doors

Rolling shutter doors need materials that can handle frequent use and tough conditions. Matt galvalume coil provides the durability and slip resistance you want. The textured surface helps prevent scratches and dents. You see these doors in shops, garages, and industrial buildings. They protect property and last for many years.

Furniture and Decorative Uses

You can use matt galvalume coil for furniture and decorative projects. The matte finish gives tables, cabinets, and shelving a modern look. Designers like the textured surface because it hides fingerprints and small marks. You find galvalume in public spaces, offices, and homes. It works well for partitions, wall panels, and even art installations. The material resists wear, so your furniture stays attractive for a long time.

Tip: Try using galvalume for custom furniture or decorative panels. You get both style and durability in one material.

Appliances and Electrical Applications

You see galvalume in many household and electrical products. Manufacturers use cold-rolled galvalume for items like washing machines, refrigerators, and ovens. The material appears in both white and brown goods. Electronics companies use galvalume for cases and panels because it resists rust and looks clean. The matte finish helps prevent fingerprints and keeps appliances looking new.

- Cold-rolled products are used in household utilities

- Applications in white and brown goods

- Utilization in the electronics industry

You benefit from the protective qualities and modern appearance of galvalume in your appliances. The material helps your devices last longer and stay in good condition.

Note: The wide range of applications of galvalume steel coil shows its value in many industries. You can rely on it for strength, style, and long-term performance.

Choosing the Right Galvalume Steel Coil

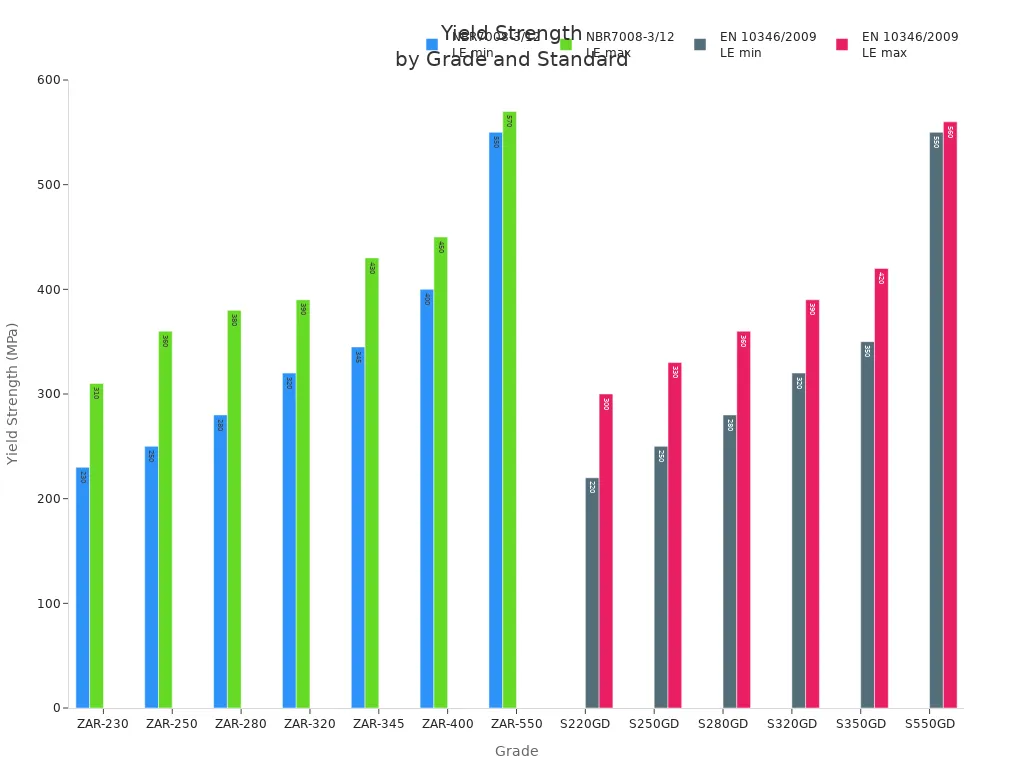

Grades and Specifications

You need to understand grades and specifications before you select a coil for your project. Grades tell you how strong and flexible the steel is. Specifications set the rules for how the coil performs in real-world conditions. You find these details in technical standards like NBR7008-3/12 and EN 10346/2009. These standards help you compare products and make the right choice for your needs.

Here is a table that shows common grades and their properties:

| Standard | Grade | LE min (MPa) | LE max (MPa) | LR min (MPa) | Elongation | Thickness (mm) |

|---|---|---|---|---|---|---|

| NBR7008-3/12 | ZAR-230 | 230 | 310 | Any | 80 | 22 |

| NBR7008-3/12 | ZAR-250 | 250 | 360 | 17 | ||

| NBR7008-3/12 | ZAR-280 | 280 | 380 | 16 | ||

| NBR7008-3/12 | ZAR-320 | 320 | 390 | 14 | ||

| NBR7008-3/12 | ZAR-345 | 345 | 430 | 12 | ||

| NBR7008-3/12 | ZAR-400 | 400 | 450 | 10 | ||

| NBR7008-3/12 | ZAR-550 | 550 | 570 | – | ||

| EN 10346/2009 | S220GD | 220 | 300 | Any | 80 | 20 |

| EN 10346/2009 | S250GD | 250 | 330 | 19 | ||

| EN 10346/2009 | S280GD | 280 | 360 | 18 | ||

| EN 10346/2009 | S320GD | 320 | 390 | 17 | ||

| EN 10346/2009 | S350GD | 350 | 420 | 16 | ||

| EN 10346/2009 | S550GD | 550 | 560 | – |

You can see how the minimum and maximum yield strengths change with each grade. This helps you pick the right coil for your building or product. If you need higher strength, choose a higher grade.

Tip: Always check the technical standard and grade before you order. This ensures your coil meets the demands of your project.

Thickness and Width Options

You must select the right thickness and width for your application. Thicker coils give you more strength and durability. Thinner coils work well for lighter structures or decorative uses. The width affects how you cut and shape the coil for your project.

Here is a quick reference for common options:

| Material | Standard | Thickness (mm) | Width (mm) |

|---|---|---|---|

| Galvalume Steel | NBR 15578 | 0.40 to 0.80 | Custom Order |

You can order custom widths to fit your design. For roofing, you may want a thicker coil. For wall panels or furniture, a thinner coil may be enough. Always match the thickness and width to the load and use.

Note: Choosing the right size helps you avoid waste and ensures your structure stays safe.

Color and Finish Selection

You can choose from many colors and finishes for your coil. The matte finish gives you a modern look and reduces glare. It also hides fingerprints and small marks. You can match the color to your building or brand. Many suppliers offer custom colors based on RAL codes or your own sample.

When you select a finish, think about where you will use the coil. For outdoor projects, the matte finish resists weather and keeps its appearance. For indoor uses, it adds style and texture. You get both beauty and performance.

Tip: Ask your supplier for color samples before you decide. This helps you get the exact look you want for your project.

Supplier Certifications

When you choose a matt galvalume coil for your project, you want to make sure you get quality and reliability. Supplier certifications help you do that. Certifications show that a supplier follows strict industry standards and uses proper quality control. You can trust certified suppliers to deliver products that meet your needs.

Why Certifications Matter

Certifications give you confidence. They prove that the supplier uses approved processes and materials. You reduce the risk of defects or failures in your project. Certified suppliers also follow safety and environmental rules. This helps you meet building codes and green standards.

Tip: Always ask your supplier for proof of certification before you place an order.

Key Certifications to Look For

You should look for suppliers who meet international and national standards. These standards cover the production, testing, and performance of galvalume steel coils. Here are some important certifications:

| Certification | What It Means | Why It Matters |

|---|---|---|

| ISO 9001 | Quality Management System | Ensures consistent product quality and process control |

| ISO 14001 | Environmental Management | Shows commitment to reducing environmental impact |

| JIS G 3312 | Japanese Industrial Standard for Prepainted Steel | Guarantees compliance with Japanese quality benchmarks |

| EN 10169 | European Standard for Organic Coated Steel | Confirms adherence to European quality and safety standards |

| ASTM A755 | American Standard for Prepainted Metallic-Coated Steel | Ensures products meet U.S. performance and durability requirements |

You can ask your supplier for certificates or test reports. These documents show that the coils have passed inspections and meet the required standards.

How to Verify Supplier Certifications

You should not just take a supplier’s word for it. You can check certifications in several ways:

- Request copies of certificates and check their validity dates.

- Look for official stamps or logos from recognized organizations.

- Contact the certifying body to confirm the supplier’s status.

- Review third-party audit reports if available.

Note: Reliable suppliers will share certification documents without hesitation.

The Impact on Your Project

Choosing a certified supplier protects your investment. You get coils that perform as promised. You avoid costly delays or replacements. Certified products also help you pass inspections and meet client expectations.

You make your project safer, more durable, and more sustainable when you work with certified suppliers. Take time to check certifications before you buy. This simple step can save you time, money, and stress.

Handling and Storage

Proper handling and storage of matt galvalume coil help you maintain its quality and extend its lifespan. You need to follow best practices from the moment you receive the coil until you install it. This section guides you through transportation, storage, and surface protection so your material stays in top condition.

Transportation Guidelines

You must transport matt galvalume coil with care. The coil’s surface can get scratched or dented if you do not use the right methods. Always secure the coil on a flat, stable surface during transit. Use padded supports to prevent pressure marks. Avoid stacking coils directly on top of each other. If you move coils with forklifts or cranes, use soft slings or protective padding.

| Transportation Tip | Why It Matters |

|---|---|

| Use padded supports | Prevents dents and scratches |

| Secure coils firmly | Reduces movement and damage |

| Avoid direct stacking | Protects the surface finish |

| Use soft slings/padding | Minimizes pressure marks |

Tip: Inspect the coil for damage before and after transportation. Early detection helps you avoid problems during installation.

Storage Conditions

You need to store matt galvalume coil in a clean, dry area. Moisture and dirt can damage the surface and reduce the coil’s lifespan. Place the coil on wooden pallets or racks to keep it off the ground. Make sure the storage area has good ventilation. Do not expose the coil to direct sunlight or rain.

To keep your coil in the best condition, follow these steps:

- Install the coil according to the manufacturer’s instructions.

- Clean the coil regularly to prevent dirt and moisture buildup.

- Keep the coil away from corrosive materials.

- Schedule preventive maintenance checks.

- Use cleaning products that do not harm the coil’s surface.

Note: Regular cleaning and maintenance help you avoid costly repairs and keep the coil looking new.

Surface Protection

You must protect the surface of matt galvalume coil from scratches, stains, and chemical exposure. Use protective films or covers if you store the coil for a long time. Avoid dragging tools or heavy objects across the surface. If you need to clean the coil, choose mild cleaning agents and soft cloths. Harsh chemicals or abrasive pads can damage the matte finish.

If you notice any stains or marks, clean them promptly. Quick action prevents permanent damage. You can also apply a temporary protective coating if you expect the coil to face tough conditions before installation.

Callout: Handle the coil gently during all stages. Careful handling keeps the surface smooth and attractive.

Proper handling and storage ensure that your matt galvalume coil performs well and looks great in your project. You protect your investment and avoid unnecessary repairs when you follow these guidelines.

Installation Steps for Matt Galvalume Coil

Preparation and Tools

You need to start with the right preparation before you install matt galvalume coil. Gather all necessary tools and materials. This step helps you avoid delays and mistakes. You should have safety gloves, safety glasses, and a dust mask. These protect you from sharp edges and dust. Use a measuring tape and a marker to plan your cuts and layout. You also need a straightedge or chalk line for marking straight lines. Keep a clean, flat workspace to prevent scratches on the coil’s surface.

Check the coil for any damage before you begin. Make sure the surface is clean and dry. Remove any protective film only when you are ready to install. This keeps the finish in top condition. Organize your tools so you can work efficiently.

Tip: Double-check your measurements before you cut. Accurate planning saves time and reduces waste.

Cutting and Shaping

You must cut and shape matt galvalume coil with care. The right technique ensures clean edges and a professional look. Use sharp, high-quality tools designed for metal. Common tools include electric shears, nibblers, or a circular saw with a metal-cutting blade. Always wear protective gear to avoid injury from sharp edges or flying metal pieces.

For best results, use precision equipment. High-quality machines give you uniform and accurate cuts. This reduces waste and helps you use the material efficiently. Many professionals use slitter services for large projects. These services offer custom cuts that fit your exact needs.

Here is a quick overview of recommended cutting and shaping methods:

| Service Type | Description |

|---|---|

| Slitter Service | Offers precise and customized cuts for coils, optimizing material use and minimizing waste. |

| Equipment Quality | High precision equipment ensures uniform and accurate cuts for any type of coil. |

After cutting, check the edges for burrs or sharp points. Smooth them with a metal file if needed. This step makes handling safer and improves the final appearance.

Note: Always cut on a stable surface to prevent bending or damaging the coil.

Fastening Methods

You need to choose the right fastening method for matt galvalume coil. The correct fasteners keep the coil secure and prevent leaks or movement. Use self-drilling screws or rivets made for metal. Stainless steel or coated fasteners work best because they resist corrosion. Place fasteners at regular intervals to hold the coil flat against the surface.

Start fastening from one end and work your way across. This helps you keep the coil straight and tight. Do not overtighten the screws. Too much pressure can dent the surface or damage the coating. Use washers if needed to spread the load and protect the finish.

Tip: Check that all fasteners sit flush with the surface. Loose or raised fasteners can cause leaks or catch debris.

Proper fastening ensures your matt galvalume coil stays in place and performs well for years.

Sealing and Finishing

You need to seal and finish matt galvalume coil to protect your installation and make it last longer. Sealing helps keep out water, dust, and other elements that can damage the steel. Finishing gives your project a clean look and adds another layer of protection.

Start by checking all seams and joints. You want to make sure there are no gaps where water can get in. Use a high-quality sealant made for metal surfaces. Many professionals choose neutral-cure silicone or polyurethane sealants. These products stick well to galvalume and stay flexible as temperatures change.

Follow these steps for effective sealing:

- Clean the area around each seam. Remove dust, oil, and debris with a soft cloth.

- Apply the sealant in a steady, even bead along the joint.

- Smooth the sealant with a gloved finger or a finishing tool. This helps the sealant fill every gap.

- Wipe away extra sealant before it dries.

Tip: Always seal fastener heads and overlaps. This prevents leaks and rust.

After sealing, you need to finish the edges and exposed surfaces. Use touch-up paint that matches the coil’s color. This paint covers small scratches or cut edges. It also helps the coil blend with the rest of your project.

Here is a quick table of recommended finishing materials:

| Area | Recommended Product | Purpose |

|---|---|---|

| Seams and joints | Neutral-cure silicone | Waterproofing |

| Fastener heads | Polyurethane sealant | Corrosion protection |

| Cut edges | Matching touch-up paint | Appearance and sealing |

Let the sealant and paint dry fully before exposing the coil to rain or heavy use. Check your work for missed spots. A careful finish keeps your installation strong and attractive.

Note: Good sealing and finishing protect your investment. You avoid costly repairs and keep your project looking new.

You can use these steps for roofs, wall panels, doors, and decorative features. Proper sealing and finishing help your matt galvalume coil perform at its best for many years.

Safety and Best Practices

When you work with matt galvalume coil, you must follow safety rules. These best practices protect you and your team. They also help you keep your project on track and avoid accidents.

Personal Protective Equipment

You need to wear the right gear before you start. Matt galvalume coil has sharp edges and a heavy weight. The right equipment keeps you safe from cuts and injuries.

Essential PPE for Working with Galvalume Coil:

| Equipment | Purpose |

|---|---|

| Cut-resistant gloves | Protect your hands from edges |

| Safety glasses | Shield your eyes from debris |

| Steel-toe boots | Guard your feet from heavy loads |

| Long sleeves/pants | Prevent scrapes and scratches |

| Dust mask | Block dust during cutting |

Tip: Always check your gear for damage before you use it. Replace worn-out items right away.

Safe Handling

You must handle matt galvalume coil with care. The coils are heavy and can cause injury if dropped or moved the wrong way. Use proper lifting techniques and tools.

- Lift with your legs, not your back.

- Work with a partner when moving large coils.

- Use forklifts, cranes, or coil lifters for heavy loads.

- Keep your hands away from pinch points.

- Never drag the coil across rough surfaces.

If you need to cut the coil, secure it on a stable surface. Use sharp tools to make clean cuts. Clean up metal shavings right after you finish.

Alert: Do not rush. Take your time to avoid mistakes and injuries.

Site Safety

You must keep your work area safe and organized. A clean site helps prevent accidents and makes your job easier.

- Mark the work zone with cones or tape.

- Store coils on flat, stable racks.

- Keep walkways clear of tools and debris.

- Post warning signs near cutting and lifting areas.

- Make sure everyone knows emergency procedures.

You should hold a safety meeting before starting big jobs. Review the plan and assign roles. Check that all equipment works before you begin.

Note: Good site safety protects you, your team, and your project. You set a strong example when you follow these best practices.

By using the right gear, handling coils safely, and keeping your site organized, you lower the risk of accidents. You also help your project run smoothly from start to finish.

Standards and Certifications for Galvalume

Industry Standards (JIS, EN, ASTM)

You need to know the main standards that guide the production and quality of galvalume. These standards help you compare products from different suppliers. They also make sure you get reliable material for your project. The most recognized standards come from Japan, Europe, the United States, and Australia. Each standard sets rules for coating, thickness, and performance.

Here is a table that shows the main international standards for galvalume and galvanized steel coils:

| Standard | Description |

|---|---|

| JIS G3302 | Japanese standard for galvanized steel coils. |

| ASTM A653 | U.S. standard for zinc-coated steel sheet by the hot-dip process. |

| EN 10327 | European standard for hot-dip galvanized steel sheet. |

| AS 1397 | Australian standard for zinc and zinc alloy coated steel sheet. |

You should check which standard your supplier follows. This helps you match the material to your project’s needs. Many projects require you to use coils that meet one or more of these standards.

Tip: Ask your supplier for details about the standard used. This makes your selection process easier and more accurate.

Quality Control and Testing

You want your galvalume to perform well and last a long time. Quality control and testing play a big role in this. Good manufacturers test every coil at different stages. They check the thickness of the coating, the strength of the steel, and the surface finish. These tests make sure the coil meets the standard you need.

You may see tests like salt spray tests, bend tests, and paint adhesion checks. These tests show how the coil will handle weather, bending, and daily use. Reliable suppliers use advanced equipment and trained staff for these checks. You can ask for test reports to see the results.

Note: Quality control protects your investment. You get a coil that meets your expectations and passes inspections.

Compliance Verification

You need to verify that your coil meets all required standards and certifications for galvalume steel coil. This step gives you peace of mind. You can ask your supplier for certificates and test results. Look for official stamps or signatures from recognized organizations. You may also contact the certifying body to confirm the documents.

You should keep these records for your project files. They help you pass building inspections and meet client demands. If you work on international projects, these documents show that your materials meet global standards.

Callout: Always check certifications before you buy. This simple step helps you avoid problems later.

By understanding standards, quality control, and compliance, you make better choices for your project. You ensure safety, durability, and value with every coil you use.

Matt Galvalume Coil vs. Other Materials

When you choose materials for your project, you want to know how each option performs. You need to see how matt galvalume coil stands up against other common choices. This section gives you a clear comparison with galvanized steel, aluminum, and other materials. You will learn when galvalume is the best fit for your needs.

Galvalume vs. Galvanized Steel

Performance and Durability

You want your building to last. In a comparison with galvanized steel, galvalume offers better resistance to rust and corrosion. Galvalume uses an aluminum-zinc coating, while galvanized steel uses only zinc. The aluminum in galvalume forms a strong barrier that protects the steel for a longer time. You will notice that galvalume lasts two to four times longer in harsh environments.

| Property | Galvalume | Galvanized Steel |

|---|---|---|

| Coating | Aluminum-Zinc | Zinc |

| Corrosion Resistance | Excellent | Good |

| Service Life | Up to 2-4x longer | Standard |

Tip: Choose galvalume for coastal or humid areas where rust is a big concern.

Cost and Value

You want to get the most value for your money. In a comparison with galvanized steel, galvalume may cost a little more at first. However, you save money over time because you need fewer repairs and replacements. Galvalume’s longer service life means you spend less on maintenance. You get a better return on your investment.

- Lower maintenance costs

- Fewer replacements needed

- Long-term savings

Appearance

You care about how your project looks. Galvalume has a matte finish that gives a modern, stylish look. It also hides fingerprints and small scratches. Galvanized steel has a shiny, spangled surface that reflects more light. If you want a softer, more elegant appearance, galvalume is a smart choice.

Galvalume vs. Aluminum and Others

You may also consider aluminum or other metals. Aluminum is lightweight and resists rust, but it can dent more easily than galvalume. Galvalume gives you a balance of strength, durability, and cost. Other materials, like stainless steel, offer high performance but often cost much more. You get a good mix of protection, style, and value with galvalume.

| Material | Strength | Corrosion Resistance | Cost | Appearance |

|---|---|---|---|---|

| Galvalume | High | Excellent | Moderate | Matte, modern |

| Aluminum | Medium | Excellent | Higher | Shiny, smooth |

| Stainless Steel | Very High | Excellent | High | Shiny, smooth |

When to Choose Matt Galvalume Coil

You should choose matt galvalume coil when you need:

- Long-lasting protection in tough weather

- A modern, slip-resistant finish

- Low maintenance and long-term savings

- Custom colors for design flexibility

Galvalume works well for roofing, wall panels, doors, and decorative features. You get both performance and style in one material.

Note: Always match your material choice to your project’s needs for the best results.

Maintenance and Longevity

Inspection and Cleaning

You need to inspect your matt galvalume coil regularly to keep it in top condition. Start with a visual check every few months. Look for signs of dirt, stains, scratches, or rust spots. Pay close attention to seams, fasteners, and edges. These areas often show problems first.

You should follow a simple inspection checklist:

- Check for surface dirt or debris.

- Look for scratches or dents.

- Inspect for rust or discoloration.

- Examine fasteners and joints.

- Make sure protective coatings remain intact.

Tip: Use a flashlight to see hidden spots, especially under panels or in shaded areas.

Cleaning your matt galvalume coil helps it last longer. Use a soft brush or cloth to remove loose dirt. For tougher stains, mix mild soap with warm water. Gently scrub the surface, then rinse with clean water. Avoid harsh chemicals or abrasive pads. These can damage the matte finish.

Here is a quick cleaning guide:

| Task | How Often | Tools Needed |

|---|---|---|

| Remove loose dirt | Monthly | Soft brush or cloth |

| Wash with soap | Every 6 months | Mild soap, water, sponge |

| Rinse thoroughly | After washing | Clean water |

Let the surface dry completely before you inspect again. If you see any stains that do not come off, repeat the cleaning process. Always test cleaning products on a small area first.

Note: Regular cleaning prevents buildup and keeps your coil looking new.

Repair and Replacement

You may find minor damage during your inspections. Small scratches or chips can happen over time. You should repair these right away to prevent rust.

Follow these steps for small repairs:

- Clean the damaged area with mild soap and water.

- Dry the spot with a soft cloth.

- Apply touch-up paint that matches your coil’s color.

- Let the paint dry fully before exposing the area to moisture.

If you see deeper scratches or dents, you may need to use a metal filler before painting. For loose or missing fasteners, replace them with new ones that match the original type.

Alert: Do not ignore rust spots. Treat them quickly to stop them from spreading.

Sometimes, you may need to replace a section of the coil. If you see large areas of damage or corrosion, remove the affected panel. Install a new piece following the original installation steps. Always use proper safety gear when handling and cutting the coil.

You keep your matt galvalume coil strong and attractive with regular maintenance. Quick repairs and careful cleaning help you get the most value and longest life from your investment.

Tips for Construction Professionals

Maximizing Value

You want to get the most out of your investment in construction materials. To maximize value, start by planning your project carefully. Measure your site and calculate the amount of coil you need. This helps you avoid waste and extra costs. Choose the right thickness and width for each part of your project. Thicker coils work well for roofs and exterior panels. Thinner coils suit interior walls or decorative features.

You should also consider the long-term benefits. Galvalume offers excellent durability and low maintenance. When you select this material, you reduce repair costs and extend the life of your building. Use protective coatings and follow proper installation steps to keep your material in top condition.

Tip: Schedule regular inspections to catch small issues early. Quick repairs prevent bigger problems and save money.

Sourcing Quality Coils

You need to find reliable suppliers to ensure you get high-quality coils. Start by researching companies with a strong reputation. Look for suppliers who provide clear product specifications and certifications. Ask for samples or visit their warehouse if possible. This lets you check the surface finish and coating quality.

Use this checklist when sourcing coils:

- Check for international certifications like JIS, EN, or ASTM.

- Review test reports for coating thickness and adhesion.

- Confirm the supplier offers custom sizes and colors.

- Ask about their quality control process.

A good supplier will answer your questions and provide documents. You should compare prices, but do not choose based only on cost. Quality materials save you money in the long run.

| Sourcing Step | Why It Matters |

|---|---|

| Check certifications | Ensures product reliability |

| Inspect samples | Confirms surface quality |

| Review test reports | Verifies performance claims |

| Compare suppliers | Finds best value and service |

Working with Suppliers

You build strong partnerships by communicating clearly with your suppliers. Share your project details and timelines. This helps the supplier prepare your order and arrange delivery on time. Ask for updates during production and shipping. Good communication prevents delays and misunderstandings.

You should also discuss after-sales support. Ask if the supplier offers technical help or installation advice. Reliable suppliers will help you solve problems quickly. Keep records of your orders, certificates, and test results. These documents help you track quality and resolve any issues.

Note: A good relationship with your supplier leads to better service and higher quality materials for your projects.

By following these tips, you make smart choices and ensure your construction projects succeed. You get the best results when you plan ahead, choose quality materials, and work closely with trusted partners.

You have seen how matt galvalume coil brings durability, style, and value to your construction projects. You can use it for roofing, panels, furniture, and appliances. To get the best results, choose the right grade, handle coils with care, and follow proper installation steps. Always check industry standards and work with trusted suppliers.

Ready to upgrade your next project? Contact a certified supplier and explore the benefits of matt galvalume coil today!

FAQ

What is the main advantage of matt galvalume coil?

You get a material that combines corrosion resistance, durability, and a modern matte finish. This coil lasts longer than standard steel and looks great in many applications.

Can you use matt galvalume coil outdoors?

Yes, you can use it outdoors. The alu-zinc coating protects the steel from rain, sun, and harsh weather. You see it often in roofing, wall panels, and exterior cladding.

How do you clean matt galvalume coil?

Use a soft cloth or sponge with mild soap and water. Avoid harsh chemicals or abrasive pads. Rinse with clean water and let the surface dry completely.

Is matt galvalume coil available in different colors?

Yes, you can choose from many colors. Suppliers offer custom options based on RAL codes or your sample. This helps you match your project’s design.

What thicknesses and widths can you order?

You can order thicknesses from 0.10 mm to 3.00 mm and widths from 20 mm to 1250 mm. Check with your supplier for custom sizes.

Does matt galvalume coil require special tools for installation?

You should use metal-cutting tools like electric shears or nibblers. Always wear safety gear. These tools help you get clean cuts and protect the coil’s surface.

How does matt galvalume coil support sustainability?

You can recycle matt galvalume coil at the end of its life. The production process uses fewer resources. The long lifespan also means less waste over time.