When deciding between Galvalume Steel Coils and Aluminum Sheets, you must consider which material provides better value for your specific needs. Value depends on factors like initial costs, long-term durability, and adaptability to different applications. Galvalume Steel Coils stand out in industries like construction due to their corrosion resistance and heat reflectivity, while Aluminum Sheets are favored in sectors such as transportation for their lightweight properties.

Recent market data highlights the growing demand for Galvalume Steel Coils, with the market size valued at USD 9.1 billion in 2023 and projected to reach USD 13.7 billion by 2031. This growth, driven by a compound annual growth rate of 5.4%, underscores the material’s relevance in construction and industrial applications. As you weigh your options, understanding these factors will help you make an informed decision.

Key Takeaways

- Galvalume Steel Coils cost less than Aluminum Sheets. They are great for saving money on projects.

- Galvalume Steel Coils are strong and resist rust well. They work best in tough conditions and last a long time.

- Aluminum Sheets are light and bend easily. They are perfect for planes and vehicles where weight matters.

- Both materials can be recycled, but Aluminum Sheets use less energy to recycle. This makes them better for the environment.

- Galvalume Steel Coils need little care, but Aluminum Sheets might need cleaning to stay nice-looking.

- For building and factory projects, Galvalume Steel Coils are a good choice. They are cheap and last a long time.

- Aluminum Sheets look modern and are great for decoration. They can be used in many creative designs.

- Think about what your project needs, like weight, strength, or cost, to pick the right material.

Cost Comparison

Initial Costs

Galvalume Steel Coil Pricing

When evaluating initial costs, Galvalume Steel Coils often present a more budget-friendly option compared to aluminum sheets. The pricing for Galvalume Steel Coils varies based on factors like gauge thickness and finish. For instance, 24-gauge corrugated panels typically range between $1.10 and $1.50 per square foot, while 26-gauge panels cost approximately $0.75 to $1.15 per square foot. These prices make Galvalume Steel Coils an attractive choice for projects requiring cost-effective yet durable materials.

Aluminum Sheet Pricing

Aluminum sheets, on the other hand, tend to be more expensive due to the energy-intensive manufacturing process and the material’s inherent properties. Aluminum roofing systems, for example, are generally 20% to 35% pricier than steel alternatives. This cost difference reflects aluminum’s superior corrosion resistance and lightweight nature, which are highly valued in industries like transportation and aerospace. While the higher upfront cost may seem daunting, aluminum’s long-term benefits often justify the investment for specific applications.

Long-Term Costs

Maintenance Expenses

Over time, maintenance costs can significantly impact the overall value of a material. Galvalume Steel Coils require minimal upkeep due to their exceptional anti-corrosion properties. The aluminum-zinc coating not only protects the steel core but also reduces the need for frequent repairs or replacements. This makes them a cost-effective choice for environments prone to humidity or acidic conditions.

Aluminum sheets also boast excellent corrosion resistance, particularly in marine or coastal areas. However, they may require periodic cleaning to maintain their appearance and performance. While the maintenance costs for aluminum are relatively low, they can still exceed those of Galvalume Steel Coils in certain scenarios.

Lifespan and Replacement Costs

The lifespan of a material directly influences its replacement costs. Galvalume Steel Coils are designed to last for decades, even in harsh environments. Their aluminum-zinc coating ensures long-term durability, reducing the frequency of replacements and associated expenses.

Aluminum sheets also offer impressive longevity, especially when used in applications where weight and corrosion resistance are critical. However, their higher initial cost means that the overall value depends on the specific use case. For projects requiring lightweight materials with extended lifespans, aluminum may prove to be a worthwhile investment despite its higher price tag.

Cost-Effectiveness in Key Industries

In construction, Galvalume Steel Coils are widely regarded as a cost-effective solution. Their affordability, combined with excellent durability and heat reflectivity, makes them ideal for roofing and siding applications. Industries like automotive and home appliances also benefit from the material’s versatility and low maintenance requirements.

Aluminum sheets, while more expensive, excel in industries where weight reduction is a priority. Transportation and aerospace sectors, for instance, rely on aluminum’s lightweight properties to improve fuel efficiency and performance. Although the upfront costs are higher, the long-term savings in fuel and maintenance often offset the initial investment.

Durability and Performance

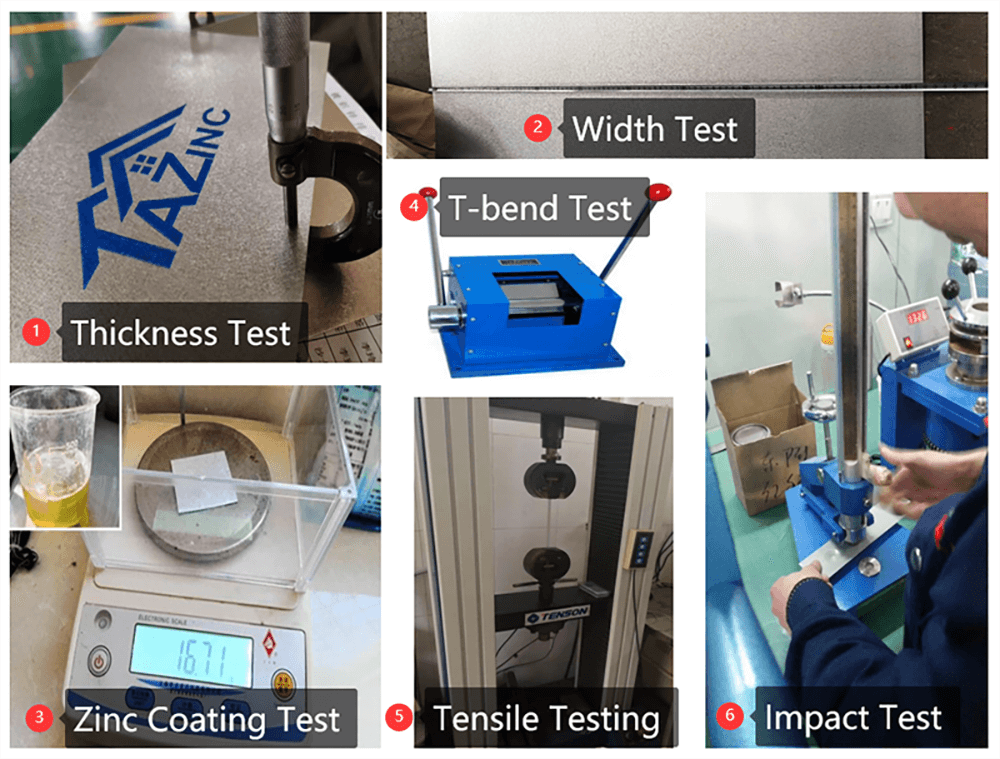

Corrosion Resistance

Galvalume Steel Coil in Harsh Environments

When it comes to corrosion resistance, Galvalume Steel Coil stands out as a top performer. Its unique aluminum-zinc coating provides a dual-layer defense against rust. The zinc layer acts as a sacrificial barrier, while the aluminum forms a protective oxide layer when exposed to moisture or air. This combination ensures long-lasting durability, even in environments with high humidity or acidic conditions.

To illustrate its superior performance, consider the following data on red rust appearance under accelerated testing conditions:

| Coating Type | Hours to Red Rust Appearance |

|---|---|

| G90 | 200 |

| G60 | 400 |

| G40 | 600 |

| Galvalume | 4000 – 8000 (20 to 40 times longer than G90) |

This table highlights how Galvalume Steel Coil outperforms traditional galvanized coatings by a significant margin. If your project involves exposure to harsh weather or corrosive elements, this material offers unmatched reliability.

Aluminum Sheets and Corrosion Resistance

Aluminum sheets also excel in resisting corrosion, particularly in marine and coastal environments. The material naturally forms a thin oxide layer that shields it from further degradation. This makes aluminum an excellent choice for applications near saltwater or in areas with frequent rainfall.

However, aluminum’s corrosion resistance depends on the specific alloy and environmental conditions. While it performs well in most scenarios, it may require additional coatings or treatments in highly acidic or alkaline settings. For projects where lightweight materials and corrosion resistance are equally critical, aluminum sheets provide a dependable solution.

Structural Strength

Load-Bearing Capacity of Galvalume Steel Coil

Galvalume Steel Coil offers impressive structural strength, making it ideal for load-bearing applications. Its steel core provides exceptional rigidity, allowing it to support heavy loads without bending or warping. This strength is particularly valuable in construction projects, where materials must withstand significant stress over time.

For example, roofing systems made from Galvalume Steel Coil can endure heavy snow loads and strong winds. The material’s durability ensures that it maintains its structural integrity, reducing the risk of damage or failure. If your project demands a robust and reliable material, this steel coil delivers both strength and peace of mind.

Flexibility and Strength of Aluminum Sheets

Aluminum sheets, while not as rigid as steel, offer a unique combination of flexibility and strength. This makes them suitable for applications requiring lightweight yet durable materials. Aluminum’s malleability allows it to be easily shaped into complex forms, which is why it is widely used in industries like aerospace and transportation.

For instance, aircraft fuselages and automotive panels often rely on aluminum sheets for their ability to absorb impact without cracking. This flexibility, combined with its corrosion resistance, makes aluminum a versatile choice for projects where weight reduction and adaptability are key priorities.

Heat Resistance

High-Temperature Applications of Galvalume Steel Coil

Galvalume Steel Coil excels in high-temperature environments, thanks to its aluminum-zinc coating. This material can withstand temperatures exceeding 300 degrees Celsius without losing its structural integrity. Its high heat reflectivity—twice that of traditional galvanized steel—makes it an excellent choice for thermal insulation applications.

You’ll find this material commonly used in chimney pipes, ovens, and industrial lighting fixtures. Its ability to endure extreme heat while maintaining durability ensures long-term performance in demanding conditions. If your project involves exposure to high temperatures, Galvalume Steel Coil offers a reliable and cost-effective solution.

Aluminum Sheets in Thermal Applications

Aluminum sheets also perform well in thermal applications, particularly where heat dissipation is crucial. The material’s high thermal conductivity allows it to distribute heat evenly, making it ideal for use in heat exchangers, radiators, and electronic enclosures.

However, aluminum’s lower melting point compared to steel limits its use in extremely high-temperature environments. For applications requiring moderate heat resistance and excellent thermal conductivity, aluminum sheets provide an efficient and lightweight option.

Uses of Galvalume Steel Coil

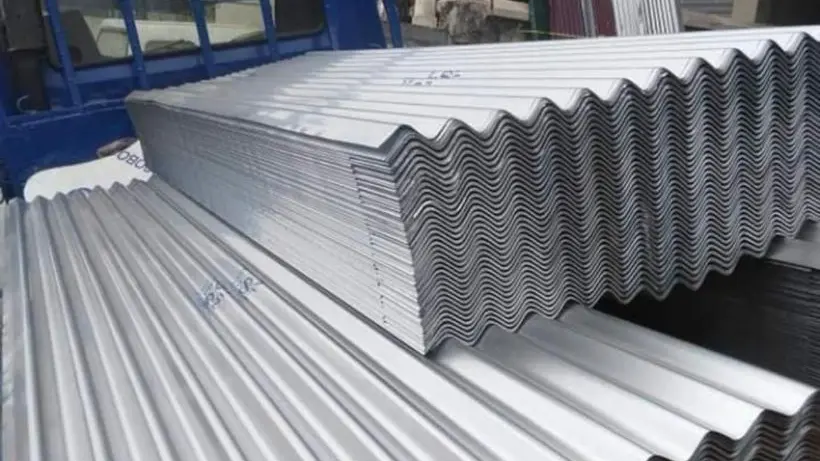

Roofing and Siding

Galvalume Steel Coil is a top choice for roofing and siding applications due to its exceptional durability and corrosion resistance. Its aluminum-zinc coating protects against rust, even in humid or acidic environments. This makes it ideal for residential and commercial buildings in regions with harsh weather conditions. The material’s smooth, spangled surface also enhances its aesthetic appeal, allowing you to achieve both functionality and style. Additionally, its high heat reflectivity helps reduce energy costs by keeping interiors cooler, making it a practical option for energy-efficient construction projects.

Industrial and Commercial Projects

In industrial and commercial settings, Galvalume Steel Coil offers unmatched versatility. Its structural strength and ability to withstand high temperatures make it suitable for demanding applications like factory roofing, storage tanks, and HVAC systems. The material’s ease of customization allows you to tailor it to specific project requirements, whether you need a particular thickness, finish, or grade. Industries such as automotive and home appliances also benefit from its durability and low maintenance needs. For example, it is commonly used in the production of air conditioners and refrigerators, where long-lasting performance is essential.

Uses of Aluminum Sheets

Transportation and Aerospace

Aluminum sheets are indispensable in the transportation and aerospace industries. Their lightweight nature reduces the overall weight of vehicles and aircraft, improving fuel efficiency and performance. This makes them a preferred material for manufacturing car body panels, aircraft fuselages, and even spacecraft components. Aluminum’s flexibility allows it to be shaped into complex forms without compromising strength, ensuring safety and reliability in critical applications. If you’re working on projects where weight reduction is a priority, aluminum sheets provide an optimal solution.

Residential and Decorative Applications

In residential and decorative applications, aluminum sheets shine for their versatility and modern appeal. They are widely used in roofing systems, facade panels, and cladding for energy-efficient buildings. According to market analysis, aluminum sheets account for 30% of the market in these areas, playing a significant role in sustainable construction. Additionally, their corrosion resistance and ease of maintenance make them ideal for decorative elements like wall panels, furniture, and signage. For large-scale commercial projects, such as malls and stadiums, aluminum sheets are often the material of choice due to their durability and sleek appearance.

| Application Area | Percentage of Market | Key Insights |

|---|---|---|

| Aluminum Sheets and Plates | 30% | Used for roofing systems, facade panels, and cladding; significant in energy-efficient buildings. |

| Commercial Infrastructure | 40% | Preferred for large-scale projects like malls and stadiums; crucial in high-rise construction. |

| Urbanization Impact | N/A | High urbanization rates in Asia-Pacific drive aluminum usage in construction. |

As urbanization continues to rise, particularly in regions like Asia-Pacific, aluminum sheets are becoming increasingly important in modern construction. Their ability to combine functionality with aesthetic appeal ensures they remain a popular choice across various industries.

Environmental Impact

Sustainability

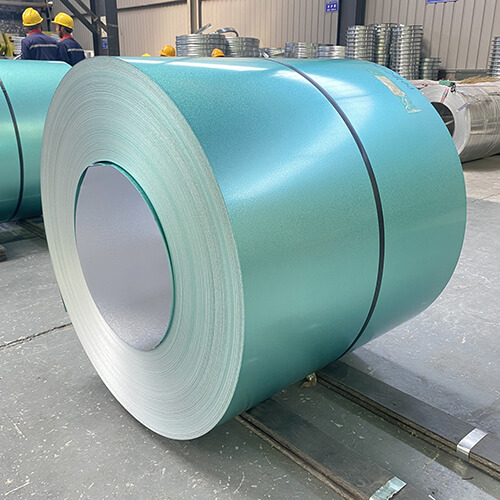

Recycling Galvalume Steel Coil

When considering sustainability, Galvalume Steel Coils offer significant advantages due to their recyclability. The steel core, combined with the aluminum-zinc coating, can be fully recycled without losing its original properties. This makes it an environmentally responsible choice for industries aiming to reduce waste.

Steel recycling is one of the most efficient processes in the materials industry. According to the World Steel Association, over 85% of steel products are recycled globally. By choosing Galvalume Steel Coils, you contribute to this circular economy, minimizing the environmental footprint of your projects.

Tip: If your project prioritizes eco-friendly materials, Galvalume Steel Coils align well with sustainability goals. Their recyclability ensures that even at the end of their lifecycle, they remain a valuable resource.

Recycling Aluminum Sheets

Aluminum sheets also excel in sustainability, boasting a near-perfect recycling rate. Unlike many materials, aluminum can be recycled indefinitely without degrading in quality. This makes it one of the most sustainable metals available today.

Recycling aluminum requires only 5% of the energy used to produce primary aluminum. This energy efficiency significantly reduces greenhouse gas emissions, making aluminum sheets an excellent choice for environmentally conscious projects. Industries like transportation and construction benefit from this, as they can reuse aluminum components while maintaining high performance.

Note: By opting for aluminum sheets, you support a material that not only reduces waste but also conserves energy during recycling. This makes it a strong contender for projects with strict environmental standards.

Energy Efficiency

Energy Use in Galvalume Steel Coil Production

Producing Galvalume Steel Coils involves energy-intensive processes, including steelmaking and the application of the aluminum-zinc coating. However, advancements in manufacturing technology have improved energy efficiency. Modern production facilities use techniques like continuous galvanizing, which reduces energy consumption and emissions.

Additionally, the durability of Galvalume Steel Coils offsets their production energy costs. Their long lifespan means fewer replacements, reducing the overall energy demand over time. If you’re looking for a material that balances performance with energy efficiency, Galvalume Steel Coils provide a compelling option.

Energy Use in Aluminum Sheet Production

Aluminum sheet production is more energy-intensive than steel, primarily due to the extraction and refinement of bauxite ore. However, the energy efficiency of aluminum recycling offsets this initial energy cost. Recycled aluminum requires only a fraction of the energy needed for primary production, making it a sustainable choice in the long run.

For industries focused on reducing carbon footprints, aluminum sheets offer a unique advantage. Their lightweight nature also contributes to energy savings in transportation and aerospace applications, where reduced weight translates to lower fuel consumption.

Insight: While aluminum production demands more energy upfront, its recyclability and lightweight properties make it an energy-efficient choice over its lifecycle.

Maintenance and Longevity

Maintenance Needs

Cleaning and Upkeep of Galvalume Steel Coil

Galvalume Steel Coils require minimal maintenance, making them an excellent choice for long-term projects. The aluminum-zinc coating protects the surface from rust and corrosion, reducing the need for frequent cleaning. However, periodic upkeep ensures optimal performance and appearance.

To clean Galvalume Steel Coils, you can use a soft brush or sponge with a mild detergent solution. Avoid abrasive tools or harsh chemicals, as they may damage the protective coating. For stubborn stains or debris, warm water and a non-abrasive cleaner work effectively.

Tip: Inspect the surface regularly for scratches or dents. Addressing minor damages promptly prevents further deterioration and extends the material’s lifespan.

Cleaning and Upkeep of Aluminum Sheets

Aluminum sheets also require low maintenance, but their cleaning process differs slightly. The material naturally forms an oxide layer that resists corrosion, yet regular cleaning helps maintain its aesthetic appeal.

Use a soft cloth or sponge with a neutral pH cleaner to remove dirt and grime. For tougher stains, a mixture of water and vinegar can be effective. Avoid using alkaline-based cleaners, as they may react with the aluminum surface.

Note: Rinse thoroughly after cleaning to remove any residue. This step ensures the surface remains free of streaks and maintains its shine.

Lifespan

Longevity of Galvalume Steel Coil

Galvalume Steel Coils are engineered for durability. Their lifespan often exceeds 40 years, even in harsh environments. The aluminum-zinc coating provides dual protection, with zinc acting as a sacrificial layer and aluminum forming a barrier against corrosion.

This material performs exceptionally well in humid or acidic conditions. For example, roofing systems made from Galvalume Steel Coils can withstand decades of exposure to rain, snow, and UV radiation without significant degradation.

Insight: If you prioritize longevity and reliability, Galvalume Steel Coils offer a cost-effective solution for projects requiring minimal replacements.

Longevity of Aluminum Sheets

Aluminum sheets also boast impressive longevity, particularly in applications where weight and corrosion resistance are critical. Depending on the alloy and environmental conditions, aluminum sheets can last 30 to 50 years.

Their natural oxide layer protects against rust, but additional coatings or treatments may enhance durability in extreme conditions. For instance, anodized aluminum offers superior resistance to wear and corrosion, extending its lifespan even further.

Key Point: Aluminum sheets are ideal for projects where lightweight materials with extended durability are essential, such as in transportation or decorative applications.

Choosing between Galvalume Steel Coils and Aluminum Sheets ultimately depends on your specific needs and priorities. Each material offers unique advantages:

- Cost: Galvalume Steel Coils provide a budget-friendly option with low maintenance expenses, while Aluminum Sheets justify their higher price with lightweight and corrosion-resistant properties.

- Durability: Galvalume excels in harsh environments and high temperatures, whereas aluminum shines in applications requiring flexibility and moderate heat resistance.

- Applications: Galvalume suits construction and industrial projects, while aluminum dominates transportation and decorative uses.

- Environmental Impact: Both materials support sustainability through recyclability, but aluminum’s energy-efficient recycling process stands out.

Recommendation: For construction or industrial projects, Galvalume Steel Coils deliver exceptional value. If weight reduction or aesthetic appeal is critical, Aluminum Sheets may better suit your needs. Evaluate your project’s demands to make the best choice.

FAQ

What is the main difference between Galvalume Steel Coils and Aluminum Sheets?

Galvalume Steel Coils excel in durability and heat resistance, while Aluminum Sheets are lightweight and corrosion-resistant. Your choice depends on the specific requirements of your project, such as structural strength or weight reduction.

Which material is better for roofing applications?

Galvalume Steel Coils are better for roofing due to their superior corrosion resistance, heat reflectivity, and cost-effectiveness. They perform exceptionally well in harsh weather conditions, making them ideal for long-term roofing solutions.

Are both materials environmentally friendly?

Yes, both materials are sustainable. Galvalume Steel Coils and Aluminum Sheets are recyclable, reducing waste. Aluminum recycling requires less energy, making it a more energy-efficient option for eco-conscious projects.

How do maintenance needs differ between the two materials?

Galvalume Steel Coils require minimal maintenance due to their aluminum-zinc coating. Aluminum Sheets also need low upkeep but may require periodic cleaning to maintain their appearance, especially in decorative applications.

Which material is more cost-effective for large-scale construction?

Galvalume Steel Coils are more cost-effective for large-scale construction. Their lower initial cost, combined with durability and minimal maintenance, makes them a practical choice for industrial and commercial projects.

Can Aluminum Sheets handle high-temperature environments?

Aluminum Sheets perform well in moderate heat applications due to their excellent thermal conductivity. However, they are less suitable for extremely high-temperature environments compared to Galvalume Steel Coils.

What industries benefit most from using Galvalume Steel Coils?

Industries like construction, automotive, and home appliances benefit most from Galvalume Steel Coils. Their strength, corrosion resistance, and heat reflectivity make them ideal for roofing, siding, and industrial components.

Are there specific projects where Aluminum Sheets outperform Galvalume Steel Coils?

Yes, Aluminum Sheets excel in transportation and aerospace projects. Their lightweight nature improves fuel efficiency and performance, making them indispensable for vehicles, aircraft, and spacecraft components.

Tip: Evaluate your project’s priorities—such as weight, durability, or cost—to determine the best material for your needs.